This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

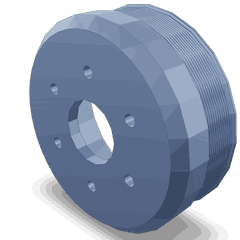

The Cummins 3095220 Fan Pulley is a critical component in commercial truck engine cooling systems. It facilitates the operation of the cooling fan, ensuring the engine maintains an optimal operating temperature under various driving conditions.

Basic Concepts of Fan Pulleys

A fan pulley connects the engine’s crankshaft to the cooling fan, transferring rotational force from the engine to the fan. This movement of air through the radiator is essential for dissipating heat, which is important for engine efficiency, longevity, and performance 1.

Purpose of the Cummins 3095220 Fan Pulley

This Cummins part is engineered to enhance cooling efficiency in commercial truck engines. It ensures the fan operates at the correct speed relative to engine RPM, maintaining optimal engine temperature for efficient operation and reducing the risk of overheating 2.

Key Features

The 3095220 is characterized by its robust design and high-quality materials. It features a precision-machined surface for smooth operation, durable materials that resist wear and corrosion, and a design that ensures efficient power transmission from the engine to the fan.

Benefits of Using the Cummins 3095220 Fan Pulley

Installing this part offers advantages such as improved engine cooling efficiency, enhanced performance, and longevity. It also reduces wear on associated components and may increase fuel efficiency by maintaining optimal engine temperature 3.

Installation Considerations

Proper installation is important for the effective operation of the 3095220. Following manufacturer guidelines, including specific prerequisites or the use of special tools, is recommended. Correct alignment and tensioning are important to ensure efficient operation and prevent unnecessary wear or damage.

Troubleshooting Common Issues

Common issues with fan pulleys include noise, vibration, or overheating. These may indicate problems with the pulley or the cooling system. Diagnostic steps include visual inspection for wear or damage, checking alignment and tension, and ensuring the cooling fan operates correctly.

Maintenance Tips

Routine maintenance is important for the longevity and efficient operation of the 3095220. This includes regular inspection for wear or damage, cleaning to remove any buildup, and following manufacturer recommendations for replacement intervals. Proper maintenance helps prevent unexpected failures and ensures efficient cooling system operation.

Compatibility with Cummins Engines

The 3095220 is designed to fit various Cummins engine models, ensuring reliable operation of the cooling system across different applications.

- G855 Series: Ensures smooth operation of the cooling fan, maintaining engine temperature within safe limits.

- G855 CM558 and GTA855 CM558 (CM2358) G101: Engineered for seamless fit, contributing to engine efficiency and longevity.

- N14 Series: Suitable for N14 CELECT PLUS and N14 G engines, ensuring the fan operates at the correct speed for adequate cooling.

- QSX15 CM2250 ECF: Ensures efficient operation of the cooling system, maintaining engine performance and reliability.

Role of the 3095220 Fan Pulley in Engine Systems

This part is integral to the efficient operation of engine systems, specifically in the interaction between the drive mechanism and the fan. It converts rotational force from the crankshaft into motion to drive the fan, facilitating air movement across the radiator for effective engine cooling. Its design allows for efficient power transmission with minimal energy loss, contributing to overall engine performance and reliability.

Conclusion

The Cummins 3095220 Fan Pulley is a vital component in the engine cooling system of commercial trucks. Its robust design, compatibility with various engine models, and role in maintaining optimal engine temperature contribute to engine efficiency, longevity, and performance. Proper installation, maintenance, and troubleshooting are important for ensuring the effective operation of this part.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.