Introduction

The Cummins 3914461 Fan Pulley is a component designed for use in commercial trucks. It is integral to the engine cooling system, ensuring that the engine operates within optimal temperature ranges. This pulley’s role in maintaining engine efficiency and performance underscores its significance in the operation of heavy-duty vehicles 1.

Basic Concepts of a Fan Pulley

A fan pulley is a mechanical device that drives the engine’s cooling fan. It is connected to the engine’s crankshaft via a belt and rotates to turn the fan, which circulates air through the radiator to cool the engine. The pulley’s design allows it to vary the fan speed based on engine load and temperature, optimizing cooling efficiency and reducing unnecessary strain on the engine 2.

Purpose of the Cummins 3914461 Fan Pulley

The Cummins 3914461 Fan Pulley plays a role in the engine cooling system by efficiently transferring rotational force from the engine to the cooling fan. This ensures that the fan operates at the correct speed to maintain optimal engine temperature. Proper cooling is vital for engine longevity and performance, making the fan pulley a key component in the system 3.

Key Features

The Cummins 3914461 Fan Pulley is characterized by its robust design and high-quality materials. It features a durable construction that can withstand the rigors of commercial truck operation. The pulley is engineered to provide precise fan speed control, enhancing cooling efficiency. Its design includes provisions for easy installation and maintenance, ensuring it meets the demands of heavy-duty applications.

Benefits

The Cummins 3914461 Fan Pulley offers several advantages. It contributes to improved engine cooling efficiency, which helps maintain engine performance and longevity. By ensuring the engine stays within optimal temperature ranges, the pulley reduces the risk of overheating and associated engine wear. Additionally, its efficient design can lead to enhanced overall truck performance by ensuring the engine operates under the best possible conditions.

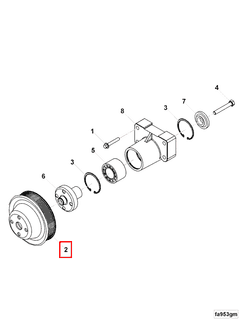

Installation Process

Installing the Cummins 3914461 Fan Pulley requires careful attention to detail. The process involves removing the old pulley, aligning the new pulley with the crankshaft, and securing it in place. Tools such as wrenches and pulley removal tools may be necessary. It is important to ensure the pulley is correctly fitted to avoid issues such as misalignment or improper belt tension, which can affect engine cooling performance.

Common Issues and Troubleshooting

Fan pulleys can encounter issues such as noise, vibration, or failure to engage properly. These problems may arise from wear, misalignment, or belt issues. Troubleshooting steps include inspecting the pulley and belt for signs of wear, ensuring proper alignment, and checking belt tension. Addressing these issues promptly can prevent more significant problems and ensure the cooling system operates efficiently.

Maintenance Tips

Regular maintenance of the Cummins 3914461 Fan Pulley is crucial for its longevity and performance. This includes periodic inspections for signs of wear or damage, ensuring the belt is properly tensioned, and checking for proper alignment. Addressing any issues early can prevent more significant problems and ensure the cooling system remains efficient.

Cummins Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation in automotive components. With a rich history of providing reliable and high-performance parts, Cummins has established a reputation for excellence. The company’s focus on advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the industry.

Compatibility with Cummins Engines

The Fan Pulley part number 3914461, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral for the proper functioning of the engine’s cooling system, ensuring that the fan operates smoothly and efficiently.

Small Bore Engines

- 4B3.9

- 6B5.9

- B4.5

- B4.5 RGT

- F4.5 CM2620 F141C

- QSB3.9 30 CM550

These engines, often found in smaller machinery and vehicles, benefit from the precise fit and reliable performance of the 3914461 Fan Pulley.

Medium Bore Engines

- 6C8.3

- B5.9 G

- B5.9 GAS PLUS CM556

- G5.9

- G5.9 CM558

- ISC CM554

- QSB4.5 CM2250 EC

- QSB4.5 CM850(CM2850)

- QSB5.9 30 CM550

- QSB5.9 44 CM550

The medium bore engines listed above, which are used in a variety of industrial and commercial applications, are also compatible with the 3914461 Fan Pulley. This compatibility ensures that these engines maintain optimal cooling performance.

Large Bore Engines

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISC CM850

- ISL CM554

- ISL9 CM2150 SN

- QSB6.7 CM850(CM2850)

The large bore engines, typically used in heavy-duty applications, also utilize the 3914461 Fan Pulley. This part is crucial for these engines to manage the increased demands of larger cooling systems.

Each of these engines relies on the 3914461 Fan Pulley for effective heat dissipation and overall engine health. Cummins has ensured that this part is engineered to meet the specific needs of each engine type, providing a reliable and durable solution for maintaining engine performance.

Role of Part 3914461 Fan Pulley in Engine Systems

The 3914461 Fan Pulley is an integral component in the efficient operation of various engine systems. It is primarily responsible for the mechanical transfer of power from the engine’s crankshaft to the fan, ensuring optimal cooling of the engine.

Interaction with the Drive System

The fan pulley is connected to the engine’s drive system via a belt. This belt transfers rotational force from the crankshaft to the pulley. The pulley’s design allows for efficient power transmission, minimizing slippage and ensuring consistent fan operation.

Coordination with the Alternator

In many engine setups, the alternator is also driven by the same belt system. The fan pulley’s position and design help maintain proper belt tension, which is essential for the alternator’s efficient operation. Proper belt tension ensures that the alternator can generate sufficient electrical power for the vehicle’s systems.

Fan Operation

The primary function of the fan pulley is to drive the engine’s cooling fan. As the pulley rotates, it spins the fan, which draws air through the radiator to cool the engine. The pulley’s design allows for variable fan speeds, which can be adjusted based on the engine’s temperature, ensuring efficient cooling under various operating conditions.

Mounting and Stability

The fan pulley is mounted on the engine’s front, typically on the crankshaft or a dedicated shaft. Its mounting must be secure to withstand the forces generated during operation. Proper mounting ensures that the pulley remains aligned with the belt and other driven components, contributing to the overall stability and efficiency of the engine system.

Integration with the Fan Drive

In some engine systems, the fan drive may include additional components such as clutches or viscous couplings. The fan pulley works in conjunction with these components to provide variable fan speeds. This integration allows the engine to maintain optimal temperature while minimizing drag and improving fuel efficiency.

Conclusion

The Cummins 3914461 Fan Pulley is a critical component in the engine cooling system of commercial trucks. Its robust design, precise fan speed control, and compatibility with a wide range of Cummins engines make it an essential part for maintaining engine performance and longevity. Regular maintenance and proper installation are key to ensuring the efficient operation of this part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.