This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

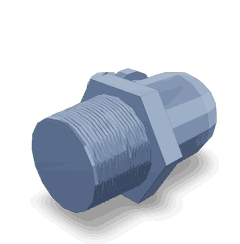

The Cummins 3335098 Grease Fitting is a component designed for the maintenance of commercial trucks. It facilitates the lubrication process, which is vital for the smooth operation and longevity of truck components. This fitting is integral to ensuring that moving parts within the truck’s system receive adequate lubrication, thereby reducing friction and wear 1.

Basic Concepts of Grease Fittings

Grease fittings are components that allow for the introduction of grease into various parts of a vehicle’s lubrication system. They play a role in ensuring that moving parts are adequately lubricated, which helps in reducing friction, minimizing wear, and enhancing the overall efficiency of the vehicle 2. In the automotive industry, several types of grease fittings are utilized, each designed to meet specific requirements and applications. These fittings vary in design and function, catering to different lubrication needs and system pressures.

Purpose of the 3335098 Grease Fitting

The 3335098 Grease Fitting is designed to contribute to the lubrication of moving parts within commercial trucks. By providing a pathway for grease to be introduced into these parts, it plays a role in maintaining optimal lubrication levels. This, in turn, helps in preventing excessive wear and tear on components, ensuring that the truck operates smoothly and efficiently over time.

Key Features

The 3335098 Grease Fitting is constructed with specific design and material considerations to ensure durability and effectiveness. It is made from materials that can withstand the pressures and conditions within a truck’s lubrication system. The fitting is designed to be compatible with various lubrication systems, ensuring that it can be effectively integrated into different truck models. Its construction also ensures that it can provide a secure and reliable connection for grease application.

Benefits

Utilizing the 3335098 Grease Fitting in commercial trucks offers several advantages. It contributes to improved lubrication efficiency, which can lead to extended component lifespan and reduced maintenance costs. By ensuring that parts are properly lubricated, the fitting helps in maintaining the overall performance and reliability of the truck.

Installation Process

Installing the 3335098 Grease Fitting requires following a specific process to ensure a secure and effective fit. This involves using the appropriate tools, preparing the fitting and the area where it will be installed, and following best practices for installation. Proper installation is key to ensuring that the fitting functions as intended, providing reliable lubrication to the truck’s components.

Troubleshooting and Maintenance

Common issues with grease fittings can include wear, leakage, or improper installation. Identifying these issues early can help in maintaining the effectiveness of the 3335098 Grease Fitting. Regular maintenance practices, such as checking for signs of wear or leakage and ensuring that the fitting is securely in place, can contribute to its longevity and performance. When issues are identified, it may be necessary to replace the fitting to ensure continued reliable operation.

Lubrication Best Practices

Selecting the appropriate type of grease for use with the 3335098 Grease Fitting is important for optimizing performance. It is also beneficial to follow recommended lubrication schedules and amounts to prevent over-greasing or under-greasing, which can affect the fitting’s effectiveness and the overall lubrication system of the truck.

Cummins Overview

Cummins Inc. is a company with a significant history and role in the commercial truck industry. Known for its commitment to quality and innovation, Cummins produces a range of automotive components designed to enhance the performance and reliability of commercial vehicles. The 3335098 Grease Fitting is one example of Cummins’ dedication to providing high-quality, durable components for the maintenance and operation of commercial trucks.

Grease Fitting 3335098 in Cummins Engines

The Grease Fitting 3335098, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to facilitate the lubrication process, ensuring that moving parts within the engine receive the necessary grease to maintain smooth operation and longevity.

In the V28 engine series, the Grease Fitting 3335098 is strategically placed to service critical points where grease is required to prevent wear and tear. Its placement is crucial for maintaining the integrity of the engine’s components, particularly in areas that are prone to friction and movement.

For the V28 engine, the Grease Fitting 3335098 is typically located in areas such as the steering linkage, suspension joints, and other pivot points. These locations are chosen based on their exposure to movement and the potential for grease depletion, which can lead to increased friction and mechanical failure if not properly maintained.

The design of the Grease Fitting 3335098 ensures that it can withstand the operational conditions of the engine, including high temperatures and pressures. This durability is essential for maintaining the reliability and performance of the engine over its operational life.

In Cummins engines, the Grease Fitting 3335098 is part of a broader maintenance strategy that emphasizes the importance of regular lubrication checks and servicing. This part’s integration into the engine’s design underscores Cummins’ commitment to providing high-quality, reliable components that contribute to the overall efficiency and durability of their engines.

Role of Part 3335098 Grease Fitting in Engine Systems

The Part 3335098 Grease Fitting is integral to the maintenance and operation of various engine components. It facilitates the lubrication process, ensuring smooth and efficient functioning of moving parts.

Connection Points

The grease fitting is strategically placed at connection points where lubrication is necessary to reduce friction and wear. These points often include joints and pivots that experience significant stress during engine operation.

Water Inlet and Pump Systems

In systems involving water inlet and pumps, the grease fitting plays a supportive role. It ensures that the moving parts of the water pump, such as the impeller and bearings, remain well-lubricated. This is particularly important in preventing corrosion and ensuring the longevity of the pump components.

Engine Rotation Components

For components that are directly involved in engine rotation, such as the crankshaft and camshaft, the grease fitting provides essential lubrication. This helps in maintaining the precision and reliability of the engine’s rotational movement.

Idler Pulley

The idler pulley, which is part of the belt drive system, benefits significantly from the grease fitting. Regular lubrication through this fitting ensures that the pulley operates smoothly, reducing the risk of belt slippage and enhancing the overall efficiency of the engine’s accessory drive system.

Water Pump and Idler Assembly

In the water pump and idler assembly, the grease fitting is vital for lubricating the idler pulley and the water pump bearings. This lubrication is essential for the seamless operation of the assembly, contributing to the efficient circulation of coolant through the engine.

Water Pump Assembly

Within the water pump assembly, the grease fitting ensures that all moving parts, including seals and bearings, are adequately lubricated. This is key to preventing overheating and ensuring consistent coolant flow, which is vital for engine temperature regulation.

Conclusion

In summary, the Part 3335098 Grease Fitting is a fundamental component in the lubrication strategy of engine systems, enhancing the performance and durability of various interconnected parts. Its role in facilitating the lubrication process is crucial for maintaining the smooth operation and longevity of commercial truck components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.