This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

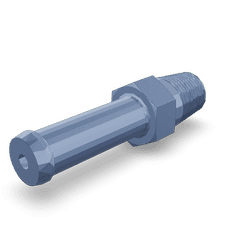

The 4943711 Orifice Connector Fitting is a component manufactured by Cummins, a well-established name in the commercial truck industry. This fitting is designed for use in various truck models, playing a significant role in the fluid systems of these vehicles.

Basic Concepts of Orifice Connector Fittings

An Orifice Connector Fitting is a device used in fluid systems to regulate the flow of liquids or gases. It operates by creating a restriction in the flow path, which can be used to control pressure, flow rate, or to mix fluids. The fitting typically consists of a small opening or orifice through which the fluid passes, and its size and shape are critical to its function 1.

Purpose of the 4943711 Orifice Connector Fitting

The 4943711 Orifice Connector Fitting is integral to the operation of a truck’s fluid systems. It helps maintain the correct flow and pressure of fluids, which is vital for the efficient operation of the engine and other systems. By regulating the flow, it ensures that the system operates within the desired parameters, contributing to the overall performance and reliability of the truck 2.

Key Features

The 4943711 Orifice Connector Fitting is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes precise orifice sizing, which is critical for its function in regulating fluid flow. Additionally, the fitting is engineered to withstand the high pressures and temperatures common in truck fluid systems, enhancing its performance and longevity 3.

Benefits

The use of the 4943711 Orifice Connector Fitting offers several benefits. It contributes to improved system efficiency by ensuring that fluids are delivered at the correct pressure and flow rate. Its durable construction and reliable performance help reduce the need for frequent replacements, offering cost savings over time. Moreover, the fitting’s precise regulation of fluid flow can lead to enhanced engine performance and fuel efficiency 4.

Installation Process

Installing the 4943711 Orifice Connector Fitting requires careful attention to detail to ensure proper function. The process involves cleaning the installation site, applying the appropriate sealant, and using the correct tools to secure the fitting in place. It’s important to follow the manufacturer’s guidelines to avoid damage to the fitting or the surrounding system components.

Common Issues and Troubleshooting

Common issues with the 4943711 Orifice Connector Fitting may include leaks, blockages, or incorrect flow rates. Troubleshooting these issues involves inspecting the fitting for signs of wear or damage, checking the connections for proper sealing, and ensuring that the orifice is not obstructed. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s fluid systems.

Maintenance Tips

Regular maintenance of the 4943711 Orifice Connector Fitting is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the fitting to remove any buildup that could affect its function, and verifying that all connections are secure and properly sealed. Adhering to these maintenance practices can help prevent issues and ensure the fitting continues to operate effectively.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial vehicles.

Orifice Connector Fitting 4943711 by Cummins: Compatibility with Various Engine Models

The Orifice Connector Fitting 4943711, manufactured by Cummins, is a critical component designed to ensure proper fluid flow and pressure regulation within various engine systems. This fitting is compatible with a wide range of Cummins engine models, each of which may have specific configurations and requirements. Below is a detailed overview of the engine models that this fitting is designed to work with:

B6.7 Series

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- L8.9 CM2670 L134C

The B6.7 and L8.9 series engines, particularly those with the CM2670 designation, benefit from the precise fluid management provided by the 4943711 fitting. These engines are known for their robust performance and reliability, often used in heavy-duty applications.

ISB Series

- ISB CM550

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

The ISB series engines, including the CM550 and CM2150 variants, are designed for versatility and efficiency. The 4943711 fitting ensures that these engines maintain optimal fluid dynamics, crucial for their performance in various operational environments.

ISBE Series

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series engines, with their CM2150 and CM800 designations, are engineered for high-performance applications. The 4943711 fitting is integral to maintaining the precise fluid control necessary for these engines to operate efficiently.

ISC and ISL9 Series

- ISC CM850

- ISL9 CM2150 SN

The ISC and ISL9 series engines, particularly the CM850 variant, are known for their durability and power. The 4943711 fitting ensures that these engines receive the correct fluid flow, enhancing their operational efficiency and longevity.

QSB Series

- QSB5.9 44 CM550

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

- QSC8.3 CM850 (CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM850 (CM2850)

- QSL9.3 CM2880 L113

The QSB series engines, including the QSC and QSL variants, are designed for a variety of applications, from agricultural to industrial use. The 4943711 fitting is essential for these engines, ensuring that they maintain the correct fluid pressure and flow, which is critical for their performance and reliability.

Role of Part 4943711 Orifice Connector Fitting in Engine Systems

The Part 4943711 Orifice Connector Fitting is integral to the efficient operation of various engine systems, particularly in managing the flow and pressure of fluids.

Engine Coolant System

In the engine coolant system, the Orifice Connector Fitting is positioned to regulate the flow of coolant between the engine block and the radiator. This regulation ensures that the coolant circulates at an optimal rate, maintaining the engine’s temperature within safe operating limits. The fitting’s precise orifice size allows for consistent coolant flow, preventing overheating and ensuring the engine operates efficiently.

Vent System

Within the vent system, the Orifice Connector Fitting plays a role in managing the pressure and flow of gases. It is often used in the crankcase ventilation system, where it helps regulate the flow of gases from the crankcase to the intake manifold. This regulation is essential for maintaining proper pressure levels within the crankcase, which in turn helps reduce emissions and improve engine performance. The fitting ensures that gases are vented efficiently, contributing to a cleaner and more effective engine operation.

Conclusion

The 4943711 Orifice Connector Fitting by Cummins is a critical component in the fluid systems of commercial trucks. Its role in regulating fluid flow and pressure is essential for the efficient operation of various engine systems. With its durable construction, precise design, and compatibility with a wide range of Cummins engine models, this fitting ensures optimal performance and reliability in demanding applications.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Barton, David C., and John D. Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.