S2268

Grease Fitting

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The S2268 Grease Fitting, manufactured by Cummins, is a component designed to facilitate the lubrication process in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts aimed at enhancing the performance and longevity of trucks. This Cummins part is significant in the maintenance regimen of these vehicles, ensuring that moving parts receive adequate lubrication to function smoothly and efficiently.

Basic Concepts of Grease Fittings

Grease fittings are components used in the lubrication systems of commercial trucks. They allow for the introduction of grease into various moving parts, such as wheel bearings and suspension components. The function of these fittings is to provide a pathway for grease to reach areas where friction occurs, thereby reducing wear and tear on the parts. Proper lubrication is vital for the efficient operation of trucks, as it minimizes friction, heat, and potential damage to components 1.

Purpose of the S2268 Grease Fitting

The S2268 Grease Fitting plays a role in the lubrication system of trucks by providing a reliable point for grease application. It is specifically designed to ensure that critical components receive consistent lubrication, which helps in maintaining their operational efficiency and extending their service life. This fitting is particularly beneficial in environments where trucks are subjected to heavy loads and harsh conditions, as it helps in reducing the friction between moving parts 2.

Key Features

The S2268 Grease Fitting is characterized by several key features that enhance its performance and durability. Its design is engineered to withstand the rigors of commercial truck operations, ensuring a secure fit and reliable grease delivery. The material used in its construction is chosen for its strength and resistance to corrosion, which is crucial in maintaining the integrity of the fitting over time. Additionally, the fitting may include unique attributes such as a sealed design to prevent contamination and ensure that the grease remains clean and effective.

Benefits of Using S2268 Grease Fitting

Utilizing the S2268 Grease Fitting offers several advantages. It contributes to improved lubrication of truck components, which in turn can lead to extended component life and enhanced overall truck performance. By ensuring that parts are well-lubricated, the fitting helps in reducing maintenance costs and downtime, as components are less likely to fail prematurely due to inadequate lubrication 3.

Installation Process

Installing the S2268 Grease Fitting requires following a step-by-step process to ensure optimal performance. The process involves preparing the fitting and the area where it will be installed, using the necessary tools to secure the fitting in place, and verifying that it is correctly installed and functioning as intended. Best practices during installation include ensuring that the fitting is clean and free from debris, and that it is tightened to the manufacturer’s specified torque to prevent leaks and ensure a secure fit.

Maintenance and Care

Regular maintenance and care of the S2268 Grease Fitting are important to ensure its continued effectiveness. This includes adhering to lubrication schedules recommended by the manufacturer to keep components well-lubricated, and performing regular inspections to check for signs of wear, leaks, or damage. Proper maintenance helps in identifying potential issues before they lead to more significant problems, ensuring the longevity and reliability of the fitting.

Troubleshooting Common Issues

Common problems associated with grease fittings can include leaks, blockages, or damage to the fitting. Addressing these issues promptly is important to maintain truck efficiency. Solutions may involve cleaning the fitting and surrounding area, replacing worn or damaged parts, or adjusting the lubrication schedule to better meet the needs of the truck’s operating conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of parts and systems designed to enhance the performance, efficiency, and durability of commercial vehicles.

Grease Fitting S2268 Compatibility with Cummins Engines

The Grease Fitting S2268 by Cummins is designed to fit seamlessly with a variety of Cummins engines, ensuring proper lubrication and maintenance. Below is a detailed overview of the engines that are compatible with this grease fitting:

GTA38 G CMEICS G116C

The Grease Fitting S2268 is compatible with the GTA38 G CMEICS G116C engine, providing essential lubrication points for optimal performance.

K Series Engines

- K19

- K38

- K50

The Grease Fitting S2268 is engineered to fit the K19, K38, and K50 engines, ensuring that critical lubrication points are accessible and maintained.

KTA19GC Series Engines

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

These engines benefit from the Grease Fitting S2268, which ensures that all necessary lubrication points are easily accessible and maintained.

NH/NT 855

The Grease Fitting S2268 is compatible with the NH/NT 855 engine, providing reliable lubrication for its components.

QSK19 Series Engines

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK19 CM2150 MCRS

- QSK19 CM850 MCRS

The Grease Fitting S2268 is compatible with the QSK19 series engines, ensuring that all necessary lubrication points are easily accessible and maintained.

QSK38 Series Engines

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

These engines are designed to work with the Grease Fitting S2268, ensuring proper lubrication and maintenance.

QSK45 and QSK50 Series Engines

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The Grease Fitting S2268 is compatible with the QSK45 and QSK50 series engines, providing essential lubrication points for optimal performance.

QSK60 Series Engines

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60 G CM2358 K110

- QSK60G

These engines are designed to work with the Grease Fitting S2268, ensuring proper lubrication and maintenance.

QSK78 and QSK95 Series Engines

- QSK78 CM500

- QSK95 CM2350 K113

The Grease Fitting S2268 is compatible with the QSK78 and QSK95 series engines, ensuring that all necessary lubrication points are easily accessible and maintained.

Role of Part S2268 Grease Fitting in Engine Systems

The S2268 Grease Fitting is an essential component in maintaining the operational efficiency of various engine systems. It facilitates the lubrication process, ensuring that moving parts within the engine operate smoothly and with reduced friction.

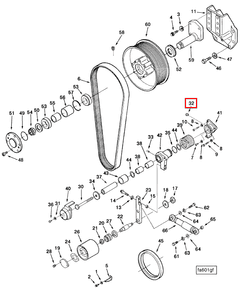

Drive Arrangement Fan and EBM-Support

In the drive arrangement fan and EBM-support systems, the S2268 Grease Fitting allows for the consistent application of lubricant to the fan’s pivot points and the EBM-support bearings. This ensures that the fan can rotate freely, enhancing cooling efficiency and reducing wear on the support structure.

Front Engine and Engine Mount

For the front engine and engine mount, the grease fitting plays a significant role in lubricating the mounting points and any pivot arms associated with the engine mount. This lubrication is vital for absorbing vibrations and maintaining the engine’s stable position within the vehicle.

Fan Idler and Flywheel

In systems involving the fan idler and flywheel, the S2268 Grease Fitting ensures that the idler pulleys and flywheel bearings receive adequate lubrication. This is important for the smooth operation of the idler assembly fan and the overall efficiency of the flywheel in storing rotational energy.

Follower and Cam

The follower and cam mechanisms benefit from the grease fitting by ensuring that the cam lobes and follower surfaces are well-lubricated. This reduces friction and wear, allowing for precise valve timing and improved engine performance.

Front Engine Supply Assembly and Idler Pulley Assembly

In the front engine supply assembly and idler pulley assembly, the S2268 Grease Fitting provides necessary lubrication to the idler pulleys and associated levers. This ensures that the pulleys can move without resistance, maintaining the integrity of the belt drive systems.

Module Fuel Control and Mounting Fan Drive

For the module fuel control and mounting fan drive, the grease fitting ensures that all moving parts within these assemblies are adequately lubricated. This is essential for the precise operation of fuel control modules and the smooth functioning of fan drive mechanisms.

Multiduct Connection and Parts Base

In the multiduct connection and parts base, the S2268 Grease Fitting helps in lubricating the connections and pivot points, ensuring that air ducts and base components can operate without undue stress or friction.

Pivot Arm Assembly and Pump Water

The pivot arm assembly and pump water systems rely on the grease fitting to keep pivot points and pump bearings well-lubricated. This is crucial for the efficient operation of water pumps and the smooth movement of pivot arms.

Radiator and Radiator Guard Package

For the radiator and radiator guard package, the grease fitting ensures that any moving components within these assemblies are lubricated. This helps in maintaining the structural integrity and operational efficiency of the cooling system.

RPTO and Assy SAE 3

In the RPTO (Remote Power Take-Off) and Assy SAE 3 systems, the S2268 Grease Fitting provides essential lubrication to gears and bearings. This ensures that power transmission components operate smoothly and with minimal wear.

Spare Mounting and Spare Parts Kit

For spare mounting and spare parts kits, the grease fitting is included to ensure that replacement components can be easily lubricated upon installation. This prolongs the lifespan of spare parts and ensures they function as intended.

Support Front Engine and Support F E

Finally, in the support front engine and support F E systems, the grease fitting plays a role in lubricating support bearings and pivot points. This is important for maintaining the structural stability and operational efficiency of the front engine support system.

Conclusion

The S2268 Grease Fitting by Cummins is a critical component in the maintenance and operation of commercial trucks. Its role in facilitating the lubrication process ensures that moving parts within the engine and other systems operate smoothly, reducing friction, wear, and potential damage. Proper installation, maintenance, and care of this fitting are essential for maximizing its benefits and ensuring the longevity and efficiency of the truck’s components.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.