This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

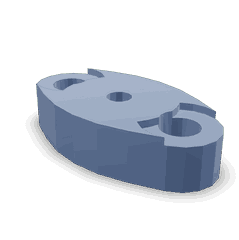

The 201017 Weld Flange, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the automotive and heavy-duty truck parts industry, produces this weld flange to meet the demanding requirements of truck operations. This part ensures secure and reliable connections within various truck systems.

Basic Concepts of Weld Flanges

Weld flanges are components used in piping and equipment connections to provide a secure and leak-proof joint. They consist of a flat, circular plate with a raised edge that is welded to the end of a pipe. Once welded, the flange can be bolted to another flange, creating a strong connection. This design allows for easy disassembly and reassembly, making weld flanges ideal for systems that require regular maintenance or modifications 1.

Purpose of the 201017 Weld Flange in Truck Operations

The 201017 Weld Flange plays a specific role in the operation of commercial trucks by providing secure connections in various truck systems. It is commonly used in fuel lines, exhaust systems, and hydraulic circuits. By ensuring a tight seal, the weld flange helps maintain system integrity, preventing leaks and ensuring efficient operation. Its application in these systems underscores its importance in maintaining the overall performance and reliability of commercial trucks 2.

Key Features of the 201017 Weld Flange

The 201017 Weld Flange boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, typically steel, which provides excellent strength and resistance to corrosion. The design specifications include precise dimensions and tolerances to ensure a perfect fit with mating components. Additionally, the weld flange may feature unique attributes such as reinforced edges or specialized coatings to further improve its durability and resistance to wear 3.

Benefits of Using the 201017 Weld Flange

Using the 201017 Weld Flange offers several advantages. It provides improved connection integrity, ensuring that systems remain leak-free and operate efficiently. The design of the flange allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, its robust construction contributes to long-term reliability, minimizing the need for frequent replacements and repairs.

Installation Process

Proper installation of the 201017 Weld Flange is crucial for ensuring its effectiveness. The process begins with preparing the pipe end to ensure it is clean and free of any debris. The flange is then welded to the pipe using appropriate welding techniques to create a strong and secure joint. After welding, the flange should be inspected for any imperfections. Once verified, the flange can be bolted to its mating component, ensuring a tight and reliable connection. Best practices include using the correct torque specifications for bolt tightening and verifying the alignment of the flanges to prevent leaks.

Maintenance and Troubleshooting

Maintaining the 201017 Weld Flange involves regular inspection routines to check for signs of wear, corrosion, or leaks. Cleaning the flange and its mating surfaces periodically helps prevent the buildup of debris that could compromise the connection. Troubleshooting common issues may involve checking for proper alignment, ensuring bolts are tightened to the correct specifications, and verifying the integrity of the weld. Any detected issues should be addressed promptly to maintain system performance.

Compatibility and Applications

The 201017 Weld Flange is designed for use in various commercial truck systems, including fuel lines, exhaust systems, and hydraulic circuits. It is compatible with a range of pipe sizes and materials, making it versatile for different applications. When integrating the flange into a system, it is important to consider compatibility with other components to ensure a seamless and efficient connection.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck parts industry. With a rich history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance components. Their product lineup includes a wide range of engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of commercial vehicle operations. Cummins’ commitment to excellence and customer satisfaction underscores their position as a leader in the industry.

Weld Flange 201017 Compatibility with Cummins Engines

The Weld Flange part number 201017, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is integral for ensuring proper sealing and connection in engine systems, providing a reliable interface for various components.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series line, known for their robustness and efficiency. The 201017 Weld Flange is compatible with these engines, ensuring a secure fit that maintains the integrity of the engine’s cooling and exhaust systems.

N-Series Engines

The N14 G and QSN14 CM876 N103 engines are part of Cummins’ N-Series, which are widely used in heavy-duty applications. The 201017 Weld Flange is engineered to fit these engines, providing a critical connection point that supports the engine’s operational demands.

NH/NT 855 Engines

The NH/NT 855 engines are another subset of Cummins’ N-Series, designed for versatility and performance. The 201017 Weld Flange is compatible with these engines, ensuring that the flange fits precisely where needed, contributing to the overall efficiency and reliability of the engine.

V-Series Engines

The V28 engine is part of Cummins’ V-Series, which is known for its power and durability. The 201017 Weld Flange is designed to fit this engine, providing a secure and reliable connection that is essential for the engine’s performance and longevity.

Each of these engines benefits from the precise engineering of the 201017 Weld Flange, ensuring that it meets the specific requirements of Cummins’ engine designs. This compatibility highlights Cummins’ commitment to providing high-quality, reliable parts that enhance the performance and durability of their engines.

Role of Part 201017 Weld Flange in Engine Systems

The part 201017 Weld Flange is a component in the integration and functionality of various engine systems. Its primary role is to facilitate secure and leak-proof connections between different parts, ensuring optimal performance and reliability.

Integration with Turbocharger Systems

In turbocharger arrangements, the Weld Flange is utilized to connect the turbocharger to the exhaust manifold. This connection is vital for maintaining the integrity of the exhaust flow, which is imperative for the efficient operation of the turbocharger. The flange ensures that the turbocharger mounting is stable and that the turbocharger oil supply hose and turbocharger oil drain hose are properly aligned and sealed.

Exhaust Manifold and Turbocharger Mounting

When dealing with the exhaust manifold and turbocharger mounting, the Weld Flange plays a significant role in securing the turbocharger lower mounting and turbocharger upper mounting components. It provides a robust connection point that can withstand the high temperatures and pressures associated with exhaust gases. This is particularly important in the heat plumbing kit where precise and reliable connections are necessary to prevent leaks and ensure efficient heat management.

Turbocharger Plumbing

In turbocharger plumbing systems, the Weld Flange is used to connect various hoses and tubes, such as the turbocharger oil supply mounting hose and turbocharger plumbing-upper and lower sections. This ensures that the oil supply to the turbocharger is consistent and that there are no leaks in the system. The flange also aids in the secure attachment of the turbocharger drain tube, which is essential for maintaining the turbocharger’s lubrication system.

Manifold and Exhaust Connections

For the manifold and exhaust connections, the Weld Flange is employed to create a sealed junction between the manifold and the exhaust system. This is critical for maintaining the exhaust flow and preventing any escape of exhaust gases, which could lead to performance issues and potential safety hazards.

Base Parts and Overall System Integrity

In the context of base parts and the overall engine system, the Weld Flange contributes to the structural integrity of the engine by providing sturdy and reliable connection points. Whether it is part of the turbocharger kit or individual turbocharger components, the flange ensures that all parts are securely fastened, contributing to the longevity and efficiency of the engine system.

Conclusion

The 201017 Weld Flange is a critical component in the maintenance and operation of commercial truck and engine systems. Its robust design, ease of installation, and compatibility with various Cummins engines make it an essential part for ensuring secure and reliable connections. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

-

G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, Automotive Systems Principles and Practice, CRC Press, 2011.

↩ -

Angelina Eret, Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves, Springer Nature, 2024.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.