This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 201341 Blind Flange is a component designed for use in commercial truck systems. It serves a specific function within the truck’s piping and tubing systems, primarily by sealing the end of a pipe. This part is integral to maintaining the integrity and efficiency of the truck’s fluid systems.

Basic Concepts of Blind Flanges

A blind flange is a type of flange that does not have a hole in the center, unlike other flanges that connect two pipes. Its primary function is to seal the end of a pipe, preventing the escape of fluids or gases. Blind flanges are used across various industries, including oil and gas, chemical processing, and automotive, to provide a secure closure for piping systems 1.

Purpose of the Cummins 201341 Blind Flange

The Cummins 201341 Blind Flange is specifically designed for use in commercial trucks. It plays a role in sealing the end of a pipe within the truck’s system, ensuring that fluids or gases remain contained within the system. This function is vital for maintaining the operational efficiency and safety of the truck’s fluid systems.

Key Features

The Cummins 201341 Blind Flange is constructed from high-quality materials, ensuring durability and reliability. Its design specifications include precise dimensions and a robust construction that can withstand high-stress environments. Unique attributes of this flange may include enhanced sealing capabilities and compatibility with various piping systems.

Benefits

Using the Cummins 201341 Blind Flange offers several advantages. Its durable construction ensures long-term reliability, while its design allows for ease of installation. The flange is also capable of withstanding high-stress environments, making it suitable for the demanding conditions often encountered in commercial truck operations.

Common Applications

The Cummins 201341 Blind Flange is typically utilized in scenarios where a secure seal at the end of a pipe is required. In commercial truck systems, this might include applications within the fuel, hydraulic, or cooling systems, where maintaining the integrity of the system is crucial for optimal performance.

Installation Procedures

Proper installation of the Cummins 201341 Blind Flange is key to ensuring optimal performance and longevity. The installation process involves cleaning the pipe end, aligning the flange, and securing it in place using appropriate fasteners. Detailed instructions should be followed to ensure a secure and effective seal.

Maintenance Tips

To prolong the service life of the Cummins 201341 Blind Flange, regular inspection and maintenance are recommended. This includes checking for signs of wear or damage, ensuring the flange remains securely fastened, and cleaning the flange and surrounding area to prevent the buildup of debris that could affect its performance.

Troubleshooting

Common issues with the Cummins 201341 Blind Flange may include leaks or damage to the flange. Troubleshooting steps can involve inspecting the flange for damage, ensuring it is properly installed, and replacing it if necessary. Addressing issues promptly can help maintain the efficiency and safety of the truck’s systems.

Safety Considerations

When working with the Cummins 201341 Blind Flange, it is important to observe safety practices and precautions. This includes ensuring the system is depressurized before beginning work, using appropriate personal protective equipment, and following all manufacturer guidelines to prevent accidents and ensure safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a strong reputation in the commercial truck industry for quality, reliability, and performance 2.

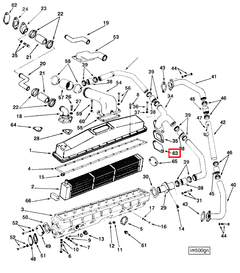

Cummins Engine Part 201341: Blind Flange Application

The Cummins part 201341, a Blind Flange, is a component used in various engine systems. This part is designed to seal the end of a pipeline, vessel, or other equipment, providing a secure and leak-proof connection. Its application in engines such as the G28 and V28 ensures that the system remains sealed and operational, preventing any fluid or gas leaks that could compromise engine performance.

In the G28 engine, the Blind Flange is often utilized in areas where a pipeline or duct needs to be terminated. This could be for maintenance purposes, where sections of the engine need to be isolated, or for permanent installation where a connection is not required. The precision engineering of the Blind Flange ensures it fits snugly, maintaining the integrity of the system.

Similarly, in the V28 engine, the Blind Flange serves the same fundamental purpose. Its application in this engine type is crucial for maintaining the engine’s operational efficiency and safety. The flange’s design allows it to be easily installed and removed, facilitating maintenance and repair work without the need for complex tools or procedures.

Both engines benefit from the use of the Cummins part 201341 Blind Flange, as it provides a reliable sealing solution that is essential for the overall functionality of the engine systems.

Role of Part 201341 Blind Flange in Engine Systems

The Blind Flange (Part 201341) is a pivotal component in various engine systems, facilitating the secure closure of openings within the engine block and other related components. Its primary function is to prevent the passage of fluids or gases through specific points in the engine, ensuring that the system operates within designed parameters.

Integration with Engine Block and Cylinder

In the engine block, the Blind Flange is often used to seal off unused ports or passages. This is particularly important in modular engine designs where certain configurations may not require all available ports to be active. By sealing these ports, the Blind Flange helps maintain the integrity of the engine’s internal pressure and prevents any unwanted leakage of lubricating oil or other fluids.

Within the cylinder assembly, the Blind Flange may be employed to cap off coolant or oil passages that are not in use for a specific engine configuration. This ensures that the fluid dynamics within the cylinder remain consistent, contributing to stable engine performance and thermal management.

Application in Filtration Systems

In filtration systems, the Blind Flange is used to seal the ends of plumbing lines that lead to or from the filter housing. This is essential in maintaining the purity of the lubricating oil by preventing contaminants from entering the system through unsealed lines. The Blind Flange ensures that the oil filtration process is effective, thereby prolonging the life of the engine components by reducing wear and tear.

Use in Oil Cooler Covers

The oil cooler cover often incorporates Blind Flanges to seal the connections between the cooler and the engine’s oil passages. This sealing is vital for the efficient operation of the oil cooling system, as it prevents oil from bypassing the cooler and ensures that the oil is adequately cooled before it is circulated back into the engine. Proper cooling of the lubricating oil is essential for maintaining optimal viscosity and performance under varying operating conditions.

Role in Performance Parts and Plumbing

In the realm of performance parts, the Blind Flange is frequently used to modify or enhance engine systems. For instance, in high-performance engines where certain stock components may be removed or altered, Blind Flanges are used to seal off the resulting openings. This is common in aftermarket modifications where stock components are replaced with performance parts that do not require all the original passages.

In plumbing applications within the engine, Blind Flanges are used to cap off sections of the cooling system or oil passages that are not utilized in a particular engine setup. This is particularly relevant in engines with aftercooler water systems, where precise control over the flow of cooling water is necessary to achieve optimal engine performance and efficiency.

Conclusion

The Blind Flange (Part 201341) plays a significant role in various engine systems by providing necessary seals and closures. Its application across different components such as the engine block, cylinder, filtration systems, oil cooler covers, performance parts, and plumbing ensures that the engine operates efficiently and reliably. The proper use of Blind Flanges is essential for maintaining the integrity of the engine’s fluid systems and overall performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.