This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

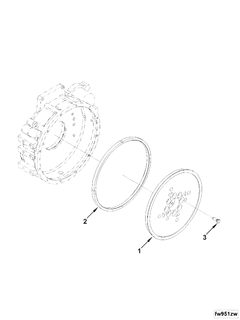

The Cummins 2830137 Flywheel is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its purpose is to store rotational energy and smooth out the power delivery from the engine to the transmission. This component is integral to the efficient and reliable performance of the truck’s engine system.

Basic Concepts of a Flywheel

A flywheel is a mechanical device specifically designed to efficiently store rotational energy. It resists changes in rotational speed by its moment of inertia. Within an engine system, the flywheel serves to stabilize the engine’s rotational speed, ensuring a consistent power delivery to the transmission. It accomplishes this by storing energy during the power stroke of the engine and releasing it during the other strokes, thereby smoothing out the power pulses 1.

Purpose of the 2830137 Flywheel

The Cummins 2830137 Flywheel is engineered to enhance the operation of commercial trucks by interacting with various engine components. It works in conjunction with the starter motor during engine start-up, providing the necessary inertia to turn over the engine. Additionally, it engages with the clutch system, facilitating smooth gear changes and power transmission from the engine to the drivetrain.

Key Features

The Cummins 2830137 Flywheel is characterized by its robust design and high-quality materials. It is constructed from durable materials to withstand the rigors of commercial truck operation. The flywheel features a precision-balanced design to ensure smooth operation and minimize vibrations. Additionally, it includes specific mounting points and alignment features to ensure proper installation and function within the engine system.

Benefits

The Cummins 2830137 Flywheel offers several advantages, including improved engine performance, enhanced durability, and increased efficiency. By providing a stable rotational mass, it contributes to smoother engine operation and more consistent power delivery. Its durable construction ensures longevity, even under the demanding conditions of commercial truck use. Furthermore, the efficient design of the flywheel contributes to overall engine efficiency, potentially leading to fuel savings.

Installation Process

Proper installation of the Cummins 2830137 Flywheel is critical for ensuring optimal performance and longevity. The process involves several steps, including preparing the engine block, aligning the flywheel with the crankshaft, and securing it in place with the appropriate fasteners. It is important to use the correct tools and follow manufacturer guidelines to ensure a proper fit and function. Additionally, precautions such as torque specifications and alignment checks should be observed to prevent installation-related issues.

Common Issues and Troubleshooting

Flywheels, including the Cummins 2830137 model, can encounter issues such as wear, warping, or damage from improper installation or use. Common symptoms of flywheel problems include difficulty starting the engine, unusual noises during operation, or issues with gear engagement. Diagnosing these issues may involve visual inspection, measurement of runout, and assessment of clutch engagement. Recommended troubleshooting steps include checking for proper installation, assessing the condition of the flywheel and related components, and performing necessary repairs or replacements as needed 2.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 2830137 Flywheel. This includes periodic inspections for signs of wear or damage, ensuring proper alignment and fit, and following manufacturer recommendations for service intervals. Additionally, maintaining the overall health of the engine and transmission system can contribute to the flywheel’s performance and lifespan.

Compatibility and Applications

The Cummins 2830137 Flywheel is designed for specific applications within the commercial truck industry. It is compatible with certain Cummins engine models and is intended for use in trucks where reliable and efficient power transmission is critical. Understanding the specific compatibility and application details is important for ensuring proper function and performance.

Historical Context of Cummins Flywheels

Cummins has a history of innovation in flywheel technology, with advancements aimed at improving performance, durability, and efficiency. The evolution of flywheel designs at Cummins reflects a commitment to enhancing the reliability and capabilities of commercial truck engines. Significant advancements have included improvements in materials, design, and manufacturing processes, contributing to the development of high-performance flywheels like the 2830137 model 3.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong presence in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicle applications.

Cummins Flywheel Part 2830137 Compatibility

The Cummins flywheel part number 2830137 is a critical component designed to work seamlessly with several Cummins engine models. This flywheel is engineered to ensure smooth engine operation by balancing the engine’s rotating assembly and reducing vibrations.

ISB CM850 and ISBE4 CM850

The flywheel part 2830137 is compatible with the ISB CM850 and ISBE4 CM850 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The flywheel’s design ensures that it can handle the high torque output and demanding operational conditions of these engines.

ISB/ISD6.7 CM2150 SN

The ISB/ISD6.7 CM2150 SN engines also benefit from the use of the 2830137 flywheel. This engine series is widely used in various industries, including construction and agriculture, due to its durability and efficiency. The flywheel’s precision engineering ensures optimal performance and longevity in these demanding environments.

ISBE CM800

The ISBE CM800 engine is another model that pairs well with the 2830137 flywheel. This engine is often found in marine and industrial applications, where reliability and performance are paramount. The flywheel’s design supports the engine’s operational needs, providing a stable and efficient power delivery.

QSB5.9 CM550

Lastly, the QSB5.9 CM550 engine is compatible with the 2830137 flywheel. This engine is known for its versatility and is used in a range of applications, from agricultural machinery to generators. The flywheel ensures that the engine operates smoothly, with minimal vibration and maximum efficiency.

Each of these engines benefits from the 2830137 flywheel’s ability to maintain balance and reduce wear, contributing to the overall reliability and performance of the engine.

Role of Part 2830137 Flywheel in Engine Systems

The flywheel, specifically part 2830137, is an integral component in the operation of engine systems, serving multiple functions that contribute to the overall efficiency and performance of the engine.

Energy Storage and Smooth Operation

The primary role of the flywheel is to store rotational energy. When the engine’s pistons move, they create an uneven power delivery. The flywheel smooths out these fluctuations by maintaining a consistent rotational speed. This stability is essential for the smooth operation of the engine, ensuring that the crankshaft continues to rotate even when the pistons are between power strokes.

Clutch Engagement

In manual transmission vehicles, the flywheel plays a key role in the clutch system. When the clutch pedal is depressed, the pressure plate is disengaged from the flywheel, allowing the driver to change gears without stalling the engine. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission and ultimately to the wheels.

Starter Motor Interaction

During engine start-up, the flywheel engages with the starter motor. The starter motor’s pinion gear meshes with the flywheel’s ring gear, initiating the engine’s rotation. This interaction is vital for the initial cranking of the engine, setting the stage for combustion and subsequent operation.

Vibration Dampening

The flywheel also acts as a vibration dampener. By absorbing and dissipating vibrations generated by the engine, it helps in reducing wear and tear on other engine components. This function is particularly important in high-performance engines where the forces and vibrations are more pronounced.

Balancing the Engine

In conjunction with the crankshaft, the flywheel helps in balancing the engine. Its mass and design contribute to counteracting the inertial forces produced by the reciprocating motion of the pistons. This balance is essential for the longevity and reliability of the engine.

Integration with Ancillary Systems

The flywheel is often connected to other ancillary systems such as the alternator and power steering pump via the crankshaft. Its consistent rotational speed ensures that these systems receive a steady input, allowing them to function efficiently and reliably.

Conclusion

In summary, the Cummins 2830137 Flywheel is a multifaceted component that enhances the performance, efficiency, and reliability of engine systems through its roles in energy storage, clutch engagement, starter motor interaction, vibration dampening, engine balancing, and integration with ancillary systems.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.