This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

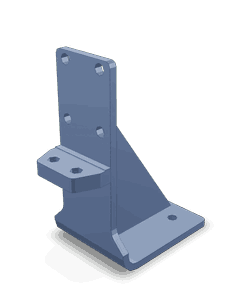

The Flywheel Housing Support 2862850 is a component designed by Cummins for use in heavy-duty truck engines. This part serves a specific function within the engine assembly, contributing to the overall performance and durability of the engine. Understanding its purpose and role is fundamental for maintaining and optimizing the engine’s operation.

Basic Concepts

Flywheel housing supports are integral to the engine assembly, providing structural support to the flywheel and facilitating its interaction with other components. The flywheel housing support ensures the flywheel is securely positioned, allowing for efficient power transfer from the engine to the transmission. It also plays a role in managing vibrations and maintaining alignment within the engine system 1.

Purpose and Role

The Flywheel Housing Support 2862850 is designed to support the flywheel in heavy-duty truck engines. By securely holding the flywheel in place, it ensures smooth and efficient power transmission. This support contributes to engine performance by reducing vibrations and maintaining the alignment of critical components. Additionally, it enhances the durability of the engine by providing a stable foundation for the flywheel 2.

Key Features

The Flywheel Housing Support 2862850 is constructed from high-quality materials, ensuring durability and reliability. Its design includes precise engineering to fit seamlessly within the engine assembly. Unique characteristics such as reinforced mounting points and vibration dampening features enhance its functionality, providing stable support and reducing operational noise 3.

Benefits

The advantages of using the Flywheel Housing Support 2862850 include improved engine efficiency through reduced vibrations and enhanced stability. This support contributes to smoother operation and increased reliability of the engine. Additionally, its robust construction ensures longevity, reducing the need for frequent replacements and maintenance 4.

Installation Process

Proper installation of the Flywheel Housing Support 2862850 involves several steps. Begin by ensuring the engine is clean and free of debris. Align the support with the mounting points on the engine block, using the provided hardware to secure it in place. Verify that all connections are tight and that the support is properly aligned with the flywheel. Conduct a thorough inspection to confirm there are no gaps or misalignments.

Common Issues and Troubleshooting

Typical problems associated with flywheel housing supports may include misalignment, wear, or damage due to vibrations. To address these issues, inspect the support for signs of wear or damage. Ensure all mounting points are secure and aligned correctly. If vibrations persist, consider additional vibration dampening measures or re-evaluating the installation process.

Maintenance Tips

To ensure the longevity and optimal performance of the Flywheel Housing Support 2862850, regular maintenance is recommended. Inspect the support during routine engine checks for signs of wear or damage. Ensure all mounting points remain secure and aligned. Clean the area around the support to prevent debris buildup, which can contribute to wear and misalignment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality and innovation. The company offers a wide range of products designed to meet the needs of various industries, including automotive, construction, and agriculture. Cummins’ reputation for reliability and performance makes it a preferred choice for heavy-duty applications.

Role of Part 2862850 Flywheel Housing Support in Engine Systems

The Flywheel Housing Support, identified as part 2862850, is integral to the structural integrity and operational efficiency of engine systems. This component is designed to provide robust support to the flywheel housing, which is a vital part of the engine’s power transmission system.

Integration with Key Components

-

Flywheel Housing: The primary function of the Flywheel Housing Support is to secure the flywheel housing in place. This ensures that the flywheel, which stores rotational energy and smooths out the power delivery from the engine, remains stable during operation.

-

Rear Engine Mount: The Flywheel Housing Support works in conjunction with the rear engine mount to absorb vibrations and reduce engine movement. This collaboration helps in maintaining the alignment and stability of the engine within the vehicle’s chassis.

-

Crankshaft: By supporting the flywheel housing, this component indirectly contributes to the stability of the crankshaft. A stable flywheel housing ensures that the rotational forces from the crankshaft are efficiently transmitted through the flywheel, enhancing engine performance.

-

Transmission Bell Housing: The Flywheel Housing Support also plays a role in aligning the transmission bell housing with the engine. Proper alignment is essential for the smooth engagement of the clutch and the transmission of power from the engine to the drivetrain.

-

Clutch Assembly: Stability provided by the Flywheel Housing Support is beneficial for the clutch assembly. It ensures that the clutch disc and pressure plate operate within the designed parameters, leading to efficient power transfer and reduced wear on clutch components.

Conclusion

In summary, the Flywheel Housing Support 2862850 is a key element in maintaining the structural and functional harmony within the engine system. Its role in supporting and aligning critical components ensures optimal engine performance and durability.

-

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Fischer, Robert, et al. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.