This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

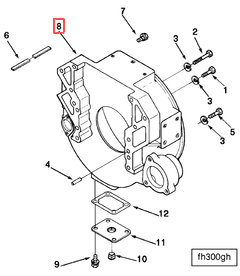

The Cummins 3002355 Flywheel Housing is a component designed for use in heavy-duty trucks. It serves a pivotal role in the engine system by supporting the flywheel and ensuring efficient power transmission from the engine to the transmission. This housing is integral to the smooth operation of the truck, contributing to both performance and reliability.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, which is a heavy rotating disc that stores rotational energy. Within the engine system, the flywheel housing interacts with several key components, including the flywheel itself, the clutch, and the transmission. Its primary function is to secure the flywheel in place and provide a stable environment for the clutch mechanism to operate, thereby facilitating the transfer of power from the engine to the transmission 1.

Purpose of the 30002355 Flywheel Housing

This Cummins part is specifically engineered to support the flywheel in heavy-duty truck applications. It plays a role in maintaining the alignment and stability of the flywheel, which is crucial for the consistent operation of the clutch system. By providing a robust enclosure, it ensures that power is transmitted smoothly and efficiently from the engine to the transmission, contributing to the overall performance and reliability of the truck.

Key Features

The 3002355 Flywheel Housing is constructed from high-quality materials that enhance its durability and performance. Key features include a robust design that withstands the rigors of heavy-duty use, precision engineering to ensure proper fit and function, and a construction that minimizes the risk of wear and tear. These attributes contribute to its longevity and effectiveness in demanding applications 2.

Benefits

The use of the 3002355 Flywheel Housing offers several benefits. It contributes to improved engine performance by ensuring efficient power transmission. Its durable construction enhances the reliability of the truck, making it suitable for heavy-duty applications. Additionally, the housing’s design helps to reduce maintenance requirements, providing cost-effective operation over the long term.

Installation Considerations

Proper installation of the 3002355 Flywheel Housing is crucial for its effective operation. It is important to follow manufacturer guidelines, use the appropriate tools, and ensure that all prerequisites are met before beginning the installation process. Careful attention to detail during installation will help to secure a proper fit and ensure the housing functions as intended.

Maintenance and Troubleshooting

Regular maintenance of the 3002355 Flywheel Housing is important for ensuring its longevity and optimal performance. This includes inspecting for signs of wear or damage, ensuring all connections are secure, and addressing any issues promptly. Common problems may include misalignment or wear on the flywheel, which can be diagnosed through careful inspection and addressed with appropriate repairs or replacements 3.

Manufacturer Information - Cummins

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to producing high-quality components. With a history of innovation and excellence, Cummins has built a reputation for reliability and performance. The company’s dedication to quality is evident in its range of products, including the 3002355 Flywheel Housing, which is designed to meet the demanding requirements of heavy-duty truck applications.

Cummins Flywheel Housing 3002355 Compatibility

The Cummins Flywheel Housing part number 3002355 is a critical component in the engine assembly, providing a housing for the flywheel and ensuring proper engine operation. This part is designed to fit seamlessly with various Cummins engines, ensuring compatibility and reliability.

V903 Engine Group

The V903 engine series by Cummins is known for its robust performance and durability. The Flywheel Housing 3002355 is specifically engineered to fit within this engine group, ensuring that it meets the stringent demands of heavy-duty applications. This compatibility is crucial for maintaining the integrity of the engine’s operation, as the flywheel housing plays a pivotal role in the engine’s overall function.

The design of the Flywheel Housing 3002355 ensures that it can withstand the high stresses and temperatures associated with the V903 engine series. This part is crafted from high-quality materials that provide durability and longevity, making it a reliable choice for those who depend on their engines for critical operations.

By ensuring that the Flywheel Housing 3002355 is compatible with the V903 engine group, Cummins guarantees that users can maintain their engines with confidence, knowing that the components are designed to work together seamlessly. This compatibility is essential for achieving optimal performance and reliability in demanding environments.

Role of Part 3002355 Flywheel Housing in Engine Systems

The flywheel housing, identified by part number 3002355, is an integral component in the operation of engine systems. It serves as the enclosure for the flywheel, which is a heavy, rotating disk that stores rotational energy and smooths out the power delivery from the engine’s combustion cycles.

Integration with Key Components

-

Flywheel: The primary role of the flywheel housing is to securely house the flywheel. This ensures that the flywheel operates within a controlled environment, minimizing vibrations and noise. The housing also protects the flywheel from external contaminants that could affect its performance.

-

Clutch Assembly: The flywheel housing interfaces directly with the clutch assembly. It provides a mounting surface for the pressure plate, which is a critical component of the clutch system. The housing must be precisely machined to ensure a proper fit and alignment with the clutch components.

-

Transmission Bell Housing: The flywheel housing connects to the transmission bell housing, forming a critical junction between the engine and the transmission. This connection ensures that the rotational energy from the flywheel is efficiently transferred to the transmission, enabling the vehicle to move.

-

Engine Block: The housing is bolted to the engine block, typically at the rear of the engine. This connection is vital for maintaining the structural integrity of the engine assembly. The housing must be robust enough to withstand the torque and vibrations generated by the engine.

-

Starter Motor: The flywheel housing often includes provisions for the starter motor. The starter motor engages with the flywheel to crank the engine during startup. The housing ensures that the starter motor is correctly aligned and secured in place.

-

Flexplate (in Automatic Transmissions): In engines equipped with automatic transmissions, the flywheel housing accommodates a flexplate instead of a traditional flywheel. The flexplate serves a similar purpose but is designed to flex slightly to absorb torque fluctuations. The housing must be compatible with the flexplate’s design.

Functional Significance

The flywheel housing plays a significant role in maintaining the balance and efficiency of the engine system. By providing a secure and precise environment for the flywheel and related components, it ensures smooth operation and reliable power transmission. The housing’s design also contributes to the overall durability and performance of the engine, making it a component of high importance in engine systems.

Conclusion

The Cummins 3002355 Flywheel Housing is a critical component in heavy-duty truck engines, ensuring efficient power transmission and contributing to the overall performance and reliability of the vehicle. Its robust design, precision engineering, and compatibility with Cummins engines make it a reliable choice for demanding applications. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing its benefits and ensuring long-term durability.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.