This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

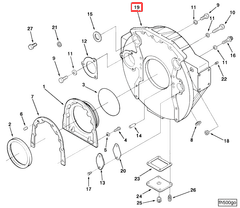

The Cummins 3013255 Flywheel Housing is a critical component for heavy-duty trucks, integral to the engine’s functionality by housing the flywheel. Understanding its purpose and significance offers insights into the performance and efficiency of heavy-duty truck engines.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure for the flywheel, a heavy rotating disc that stores rotational energy. This housing ensures the flywheel operates within a controlled environment, interacting with components like the clutch and transmission to facilitate power transfer from the engine to the drivetrain. It also contributes to the structural integrity of the engine assembly by providing a mounting point for these critical components 1.

Purpose and Role of the 3013255 Flywheel Housing

The Cummins 3013255 Flywheel Housing is engineered to enhance the operation of heavy-duty trucks. It secures the flywheel, smoothing power delivery from the engine to the transmission. This component ensures the flywheel operates under optimal conditions, supporting consistent power output and reliable gear shifting 2.

Key Features

This Cummins part is constructed from durable materials to withstand heavy-duty applications. Its design includes precise engineering for a perfect fit with engine components. Unique attributes may include enhanced sealing provisions to prevent oil leaks and robust construction to endure high torque environments 3.

Benefits of Using the 3013255 Flywheel Housing

Utilizing this part in heavy-duty trucks offers several advantages. Its durable construction contributes to the longevity of the engine system, while its precise design enhances performance. The reliability of this component ensures that heavy-duty trucks can operate under demanding conditions without compromising on efficiency or power delivery 4.

Installation and Compatibility

Proper installation of the 3013255 Flywheel Housing is vital for its correct function within the truck’s engine system. Installation guidelines recommend thorough preparation of the engine compartment, including checks for compatibility with existing engine components. Attention to detail during installation can prevent future issues and ensure the housing fits seamlessly within the engine assembly.

Maintenance and Troubleshooting

Maintaining the 3013255 Flywheel Housing is key to ensuring its longevity and optimal performance. Regular inspections for signs of wear or damage can help identify potential issues before they become critical. Troubleshooting common problems, such as oil leaks or unusual noises, may involve checking the housing’s seals and connections, ensuring they are intact and functioning as intended.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the automotive and heavy-duty truck industry, Cummins is renowned for its innovative solutions and commitment to quality. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles across multiple sectors.

Compatibility of 3013255 Flywheel Housing

The 3013255 Flywheel Housing is designed to fit seamlessly with a variety of engine models. It is crucial for maintaining the integrity and performance of the engine by housing the flywheel, which is essential for the engine’s starting mechanism and smooth operation.

V28 Engines

The 3013255 is specifically engineered to fit the V28 engine series, known for its robust design and high power output, making it suitable for heavy-duty applications. The compatibility of the flywheel housing with the V28 engine ensures that the engine can handle the stresses and demands of such applications effectively.

Grouping by Application

In addition to the V28 engines, the 3013255 is also compatible with other Cummins engines that share similar design and operational requirements. This grouping ensures that the part can be used across various models without compromising performance or reliability.

Installation and Integration

When installing the 3013255, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. This includes aligning the housing correctly with the engine block and ensuring all bolts and fasteners are tightened to the specified torque settings. Proper installation is critical for the longevity and efficiency of the engine.

Maintenance and Replacement

Regular maintenance of the flywheel housing is necessary to prevent wear and tear, which can lead to engine performance issues. When replacing the flywheel housing, it is advisable to use genuine Cummins parts to maintain the engine’s warranty and performance standards.

Role of 3013255 Flywheel Housing in Engine Systems

The 3013255 Flywheel Housing is an integral component in the assembly and operation of engine systems. It serves as the protective enclosure for the flywheel, which is a heavy rotating disc that stores rotational energy and smooths out the delivery of power from a motor to the transmission.

Integration with Key Components

-

Flywheel: The primary role of the flywheel housing is to encase the flywheel, safeguarding it from external elements and containing any potential debris that may result from wear or failure. This housing ensures that the flywheel operates within a controlled environment, maintaining the efficiency and reliability of the engine’s power delivery.

-

Clutch Assembly: The flywheel housing interfaces directly with the clutch assembly. It provides a mounting surface for the pressure plate and clutch disc, which are essential for engaging and disengaging the engine from the transmission. Proper alignment and secure fitting of the housing are vital for the smooth operation of the clutch system.

-

Torque Converter (Automatic Transmissions): In vehicles equipped with automatic transmissions, the flywheel housing interacts with the torque converter. The housing must be precisely aligned to ensure that the torque converter can effectively transfer power from the engine to the transmission, enhancing the vehicle’s drivability and performance.

-

Engine Block: The flywheel housing is bolted to the engine block, typically at the rear of the engine. This connection is critical for maintaining the structural integrity of the engine assembly. The housing must be robust enough to withstand the vibrations and stresses generated during engine operation.

-

Starter Motor: The flywheel housing also plays a role in the starting system of the vehicle. It provides a surface for the starter motor’s gear to engage with the flywheel’s ring gear, facilitating the engine’s cranking process. The housing must ensure that this engagement is smooth and reliable to prevent starter motor damage.

-

Vibration Dampening: By enclosing the flywheel, the housing contributes to reducing vibrational noise and ensuring a quieter operation of the engine. This is particularly important in high-performance engines where balance and smoothness are paramount.

Conclusion

In summary, the 3013255 Flywheel Housing is a multifaceted component that ensures the proper function and protection of the flywheel and its associated systems within the engine. Its role extends beyond mere containment, contributing to the overall performance, reliability, and efficiency of the engine.

-

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics (Springer Nature, 2023).

↩ -

Qianfan Xin, Diesel Engine System Design (Woodhead Publishing, 2011).

↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding (Cengage Learning, 2019).

↩ -

Gang Sheng, Vehicle Noise, Vibration and Sound Quality (SAE International, 2012).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.