This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

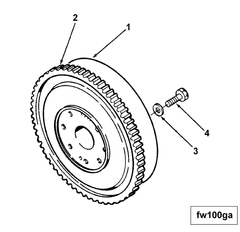

The Cummins 3023810 Flywheel is a critical component for commercial trucks, designed to store rotational energy and smooth power delivery from the engine to the transmission. This ensures consistent operation and enhances the truck’s performance and efficiency.

Basic Concepts of a Flywheel

A flywheel is a mechanical device designed to store rotational energy efficiently. It consists of a heavy disc attached to a rotating shaft, resisting changes in rotational speed. In an engine system, the flywheel maintains momentum between power strokes, ensuring a steady power supply to the transmission, resulting in smoother engine operation and reduced wear on other components 1.

Purpose of the Cummins 3023810 Flywheel

This Cummins part is integral to a truck’s engine operation. It interacts with the crankshaft to store energy during the power stroke and release it during other strokes, maintaining consistent rotational speed. This stabilizes the engine’s RPM, crucial for efficient truck operation. Additionally, the flywheel engages with the starter motor during start-up and with the clutch during gear changes, facilitating smooth transitions and reducing stress on the engine and transmission 2.

Key Features

The Cummins 3023810 Flywheel is engineered with precision for commercial trucks. Constructed from high-strength materials, it ensures durability and reliability. Its design includes balanced weight distribution and specific dimensions tailored to fit seamlessly within the engine system, contributing to its ability to withstand high torque and provide consistent performance over time 3.

Benefits

This part offers several advantages. Its robust construction and precise engineering contribute to improved engine performance by ensuring smooth power delivery. The flywheel’s durability means it can withstand the rigors of commercial truck operation, leading to longer service intervals. Additionally, its efficient design enhances overall engine efficiency, contributing to better fuel economy and reduced emissions 4.

Installation Process

Installing the Cummins 3023810 Flywheel requires careful attention to detail. The process involves removing the old flywheel, cleaning the mating surfaces, and ensuring the engine is properly aligned. The new flywheel should be installed with the correct torque specifications to ensure a secure fit. It is also important to verify that all connections, including those to the starter motor and clutch, are properly made. Following the manufacturer’s guidelines during installation will help in achieving optimal performance and longevity of the flywheel.

Common Issues and Troubleshooting

Flywheels can encounter issues such as warping, cracking, or excessive wear, which may lead to symptoms like difficulty in starting the engine, unusual noises, or vibrations during operation. Regular inspection and maintenance can help in identifying these issues early. Troubleshooting steps may include checking for proper alignment, ensuring all connections are secure, and replacing worn or damaged components as necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3023810 Flywheel, regular maintenance is recommended. This includes inspecting the flywheel for signs of wear or damage, ensuring all connections are tight, and following the manufacturer’s service intervals for replacement. Keeping the engine and transmission well-maintained will also contribute to the overall health of the flywheel.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Their commitment to excellence is reflected in the design and performance of components like the Cummins 3023810 Flywheel, which are engineered to meet the high demands of commercial truck operations.

Role of Part 3023810 Flywheel in Engine Systems

The flywheel, identified by part number 3023810, is integral to the operation of an engine system, serving as a pivotal component in the interface between the engine and transmission. Its primary function is to store rotational energy and smooth out the power delivery from the engine’s combustion cycles.

Interaction with the Engine

When the engine’s pistons move due to combustion, the flywheel absorbs the energy generated. This stored energy is then used to keep the engine running smoothly between power strokes, minimizing the jerking motion that would otherwise occur. The flywheel’s inertia helps maintain a consistent rotational speed, which is essential for the engine’s stability and efficiency.

Connection to the Transmission

The flywheel is directly connected to the engine’s crankshaft, acting as a bridge to the transmission system. In manual transmissions, the flywheel works in conjunction with the clutch. When the clutch is engaged, the flywheel transmits power from the engine to the transmission, allowing the vehicle to move. In automatic transmissions, the flywheel’s role is similar, though the connection to the transmission is managed differently.

Contribution to Starting the Engine

During engine start-up, the flywheel’s inertia plays a significant role. The starter motor engages with the flywheel to turn the engine over. Once the engine starts, the flywheel continues to spin, helping to maintain momentum and allowing the engine to reach its operating speed.

Balancing the Engine

The flywheel also contributes to balancing the engine. Its mass helps counteract the reciprocating motion of the pistons, reducing vibrations and wear on engine components. This balancing act is vital for the longevity and performance of the engine.

Thermal Management

In some engine systems, the flywheel aids in thermal management. Its mass can absorb and dissipate heat generated by the engine, helping to maintain optimal operating temperatures.

Integration with Other Components

The flywheel interacts with several other components within the engine system. For instance, it is often connected to the flexplate in automatic transmissions, which serves a similar function. Additionally, the flywheel’s design may incorporate features to facilitate the operation of the clutch assembly, ensuring smooth gear changes in manual transmissions.

Conclusion

In summary, the Cummins 3023810 Flywheel is a multifaceted component that enhances the engine’s performance, stability, and efficiency through its interactions with the crankshaft, transmission, and other engine components. Regular maintenance and proper installation are key to ensuring its longevity and optimal performance.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.