This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

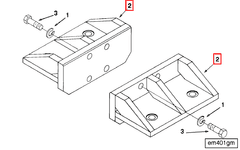

The Flywheel Housing Support, identified by Part #3058310, is a component manufactured by Cummins, a well-established name in the automotive industry. This part is integral to the operation of heavy-duty trucks, providing structural support and facilitating the interaction between several key drivetrain components.

Function and Operation

The Flywheel Housing Support plays a role in the truck’s drivetrain system by securing the flywheel in place. It ensures proper alignment and operation of the flywheel, which is essential for the efficient transfer of power from the engine to the transmission via the clutch 1. The support housing allows for the precise mounting of the flywheel, enabling smooth engagement and disengagement of the clutch. This interaction is vital for the seamless operation of the vehicle, particularly under heavy-duty conditions where precision and durability are paramount 2.

Key Features

The design of the Flywheel Housing Support is characterized by its robust construction and precision engineering. Manufactured using high-strength materials, it is built to withstand the rigors of heavy-duty use 3. The housing is engineered to provide a secure fit for the flywheel, ensuring minimal vibration and maximum efficiency. Its design also facilitates easy integration with other drivetrain components, enhancing the overall reliability and performance of the truck.

Benefits

The Flywheel Housing Support contributes to improved engine performance by ensuring the flywheel operates within specified tolerances. This precision leads to enhanced drivetrain efficiency and reduced wear on associated components 4. Additionally, the durable construction of the housing supports its longevity under demanding conditions, providing truck operators with a reliable component that can withstand the stresses of heavy-duty applications.

Installation and Compatibility

Proper installation of the Flywheel Housing Support is crucial for its effective operation. Installation procedures should follow manufacturer guidelines to ensure correct alignment and secure mounting. This may involve preparations such as cleaning the mating surfaces and verifying the condition of gaskets or seals to prevent leaks and ensure a tight fit. Compatibility with various truck models and engine types should be confirmed prior to installation to ensure optimal performance and integration within the drivetrain system.

Maintenance and Troubleshooting

Routine maintenance of the Flywheel Housing Support includes inspecting for signs of wear or damage, ensuring all fasteners are secure, and verifying the integrity of gaskets or seals. Regular checks can help identify potential issues before they lead to more significant problems. Common issues may include leaks, excessive vibration, or difficulty in clutch engagement, which can often be traced back to the housing. Troubleshooting steps may involve re-torquing fasteners, replacing worn gaskets, or, in more severe cases, inspecting the housing for cracks or deformation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes a variety of components for heavy-duty trucks, demonstrating its commitment to enhancing the performance, efficiency, and reliability of commercial vehicles. Cummins’ expertise in engine technology and component manufacturing underscores the quality and reliability of parts like the Flywheel Housing Support 5.

Conclusion

The Flywheel Housing Support part number 3058310, manufactured by Cummins, is an integral component designed to fit seamlessly with various Cummins engines. This part plays a crucial role in maintaining the structural integrity and operational efficiency of the engine by supporting the flywheel housing.

In the context of the K19 engine series, the Flywheel Housing Support ensures that the flywheel housing remains securely in place, thereby contributing to the smooth operation of the engine. The design of this part is meticulously engineered to withstand the rigors of engine operation, providing durability and reliability over time.

Additionally, the Flywheel Housing Support is compatible with other Cummins engines within the same family, ensuring a standardized fit and function across different engine models. This compatibility is essential for maintenance and repair purposes, allowing technicians to easily replace or inspect the part without the need for custom modifications.

The precision and quality of the Flywheel Housing Support are paramount, as any deviation in its fit or function can lead to significant engine performance issues. Cummins’ commitment to manufacturing excellence ensures that this part meets stringent quality standards, providing users with a dependable and long-lasting solution for their engine needs.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition (The Goodheart-Willcox Company Inc, 2016).

↩ -

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems (Springer Vieweg, 2014).

↩ -

Douglas R. Fehan, Design of Racing and High-Performance Engines 2004-2013 (SAE International, 2013).

↩ -

Cummins Inc., Company Overview, accessed March 2024, https://www.cummins.com/company/overview.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.