This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

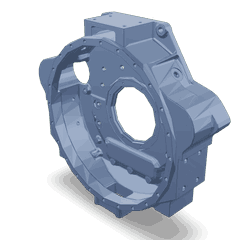

The Flywheel Housing is a critical component in the operation of heavy-duty truck engines, providing a protective enclosure for the flywheel and clutch system. Cummins, a leading manufacturer in the engine industry, produces the 3090151 Flywheel Housing, designed to meet the rigorous demands of heavy-duty applications.

Basic Concepts of Flywheel Housing

A Flywheel Housing is a structural component that encases the flywheel and clutch assembly within an engine. Its primary functions include providing a secure environment for these components, facilitating the transfer of rotational energy from the engine to the transmission, and contributing to the overall stability and balance of the engine. The housing integrates with other engine components by aligning with the crankshaft and connecting to the transmission system, ensuring smooth operation and efficient power transfer 1.

Purpose of the 3090151 Flywheel Housing

The 3090151 Flywheel Housing by Cummins plays a role in the operation of a truck engine by encapsulating the flywheel and clutch system. This housing allows for the efficient transfer of rotational energy from the engine to the transmission, which is vital for vehicle movement. It also provides structural support to the flywheel, reducing vibrations and enhancing the stability of the engine during operation 2.

Key Features

The 3090151 Flywheel Housing is constructed with high-strength materials to ensure durability and reliability under heavy-duty conditions. Its design includes precise engineering to maintain alignment with the crankshaft and transmission, which is crucial for the efficient operation of the engine. The housing is also designed to withstand high temperatures and pressures, ensuring long-term performance. Unique attributes of this housing may include enhanced sealing features to prevent leaks and improved ventilation to manage heat 3.

Benefits

The 3090151 Flywheel Housing offers several advantages, including improved engine stability due to its robust construction and precise fit. Its durable materials contribute to enhanced longevity, reducing the need for frequent replacements. Additionally, the housing’s design aids in maintaining overall engine efficiency by ensuring smooth operation of the flywheel and clutch system.

Installation Process

Proper installation of the 3090151 Flywheel Housing involves several steps to ensure correct fitting and operation. It begins with the preparation of the engine block, ensuring it is clean and free from debris. The housing is then aligned with the crankshaft and secured in place using the appropriate fasteners. Tools required may include torque wrenches to ensure proper tightening of bolts. Precautions during installation include verifying the alignment of the housing with the transmission and ensuring all seals are intact to prevent leaks.

Common Issues and Troubleshooting

Typical problems associated with Flywheel Housings can include leaks, misalignment, and wear due to high stress. Diagnostic methods involve visual inspection for signs of damage or wear, checking alignment with other components, and testing for leaks. Potential solutions may range from re-sealing the housing to realigning components or, in severe cases, replacing the housing to maintain optimal performance.

Maintenance Tips

Regular maintenance practices for the 3090151 Flywheel Housing include periodic inspection for signs of wear, ensuring all fasteners are tight, and checking for leaks. Care instructions may involve cleaning the housing to remove dirt and debris, which can contribute to wear. Following these maintenance routines can help prolong the lifespan of the housing and ensure continued efficient operation of the engine.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and efficient engine components. Their commitment to quality is evident in the design and construction of the 3090151 Flywheel Housing, which is engineered to meet the rigorous demands of heavy-duty applications.

Cummins Flywheel Housing Part 3090151 Compatibility

The Cummins flywheel housing part 3090151 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, providing a secure housing for the flywheel and contributing to the overall efficiency of the engine.

K19 Series Engines

The K19 series engines, including the K19 and QSK19 CM2350, are compatible with the flywheel housing part 3090151. This compatibility ensures that the flywheel housing fits precisely, maintaining the engine’s structural integrity and operational efficiency.

QSK19 Series Engines

The QSK19 series engines, specifically the QSK19 CM500 and QSK19 CM850 MCRS, also benefit from the use of the flywheel housing part 3090151. This part is engineered to fit these engines perfectly, ensuring that the flywheel operates smoothly and efficiently. The precision fitment of this housing is crucial for maintaining the engine’s performance and longevity.

Grouping of Compatible Engines

The flywheel housing part 3090151 is designed to fit a range of Cummins engines, including:

- K19

- QSK19 CM2350

- QSK19 CM500

- QSK19 CM850 MCRS

These engines, while differing in specifications and applications, share a common requirement for a reliable and precise flywheel housing. The part 3090151 meets this requirement, ensuring that the flywheel operates within its designed parameters, contributing to the engine’s overall efficiency and durability.

Role of Part 3090151 Flywheel Housing in Engine Systems

The Flywheel Housing, identified by part number 3090151, is an integral component in the assembly and operation of engine systems. This housing encases the flywheel, providing a secure and stable environment for it to function. The flywheel, a heavy rotating disc, is connected to the engine’s crankshaft and plays a significant role in storing rotational energy.

When the engine operates, the flywheel’s inertia helps to smooth out the power delivery between the engine’s combustion cycles. The Flywheel Housing not only protects the flywheel but also ensures that it is properly aligned with other components such as the clutch assembly and the transmission input shaft.

In manual transmission vehicles, the Flywheel Housing interfaces directly with the pressure plate of the clutch system. This interaction is essential for the efficient transfer of power from the engine to the transmission. In automatic transmissions, although the setup differs, the Flywheel Housing still plays a role in maintaining the structural integrity and alignment of the flywheel with the flexplate, which is connected to the torque converter.

Additionally, the Flywheel Housing serves as a mounting point for various engine components. It often includes provisions for attaching the starter motor, which engages with the flywheel to crank the engine during startup. The housing may also have bolt patterns for securing the engine to the transmission, ensuring a solid connection between these critical systems.

In summary, the Flywheel Housing (part 3090151) is a foundational element in the engine system, facilitating the smooth operation of the flywheel and ensuring proper integration with the clutch, transmission, and starter motor. Its design and placement are essential for the overall performance and reliability of the engine.

Conclusion

The 3090151 Flywheel Housing by Cummins is a vital component in heavy-duty truck engines, ensuring the efficient operation and longevity of the flywheel and clutch system. Its robust construction, precise engineering, and compatibility with a range of Cummins engines make it a reliable choice for maintaining engine performance and stability.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Automobile Vehicle Safety, George Peters, Barbara J Peters, CRC Press, 2002

↩ -

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.