This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

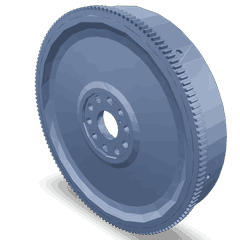

The Cummins 3093712 Flywheel is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its purpose is to store rotational energy and contribute to the smooth functioning of the engine. Understanding the flywheel’s function and significance can provide valuable insights into the overall performance and efficiency of commercial trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing energy during acceleration and releasing it during deceleration. This mechanism smooths out the power delivery from the engine, ensuring a more stable and efficient operation. Flywheels are integral to the engine’s operation, particularly in diesel engines where combustion occurs in discrete cycles 1.

Purpose of the Cummins 3093712 Flywheel

The Cummins 3093712 Flywheel is specifically engineered to enhance the performance of commercial truck engines. It plays a role in storing rotational energy, which helps to smooth out the power delivery from the engine. This results in more consistent engine operation, which can contribute to improved fuel efficiency and overall vehicle performance. The flywheel also assists in the engagement of the clutch, ensuring smooth transitions between gear changes.

Key Features

The Cummins 3093712 Flywheel is characterized by its robust design and high-quality materials. It is constructed using durable materials that can withstand the rigors of commercial truck operation. The flywheel’s design includes features that enhance its ability to store and release rotational energy efficiently. Engineering considerations such as weight distribution and balance have been meticulously addressed to ensure optimal performance and longevity.

Benefits

Using the Cummins 3093712 Flywheel offers several advantages. It contributes to improved engine performance by ensuring a smoother and more consistent power delivery. This can lead to enhanced fuel efficiency, as the engine operates more efficiently with reduced fluctuations in rotational speed. Additionally, the durable construction of the flywheel increases its longevity, providing truck operators and fleet managers with a reliable component that requires minimal maintenance.

Installation and Compatibility

Proper installation of the Cummins 3093712 Flywheel is crucial for ensuring optimal performance. It is designed to be compatible with specific truck models and engine types, ensuring a seamless integration into the engine system. Following manufacturer guidelines during installation can help prevent issues and ensure the flywheel functions as intended.

Maintenance and Troubleshooting

Maintaining the Cummins 3093712 Flywheel is relatively straightforward, but it is important to follow best practices to ensure optimal performance and longevity. Regular inspections for signs of wear or damage can help identify potential issues early. Common problems with flywheels may include uneven wear or damage to the friction surface, which can affect clutch engagement. Addressing these issues promptly can help maintain the flywheel’s performance and extend its service life.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components, with a strong reputation in the industry for innovation and quality. The company has a long history of developing reliable and efficient engine solutions for a wide range of applications, including commercial trucks. Cummins’ commitment to quality and performance is evident in their products, including the Cummins 3093712 Flywheel, which is designed to meet the demanding requirements of commercial truck operation.

Cummins Flywheel Part 3093712 Compatibility

The Cummins flywheel part number 3093712 is designed to fit seamlessly with a variety of engine models. This part is engineered to ensure optimal performance and reliability across different engine configurations. Below is a detailed description of its compatibility with specific engine models.

QST30 CM552 Engines

The Cummins flywheel part 3093712 is specifically engineered to fit the QST30 CM552 engines. This compatibility ensures that the flywheel operates efficiently within the engine’s design parameters, providing the necessary balance and power transfer. The part’s precision engineering guarantees that it will integrate smoothly with the engine’s components, enhancing overall performance.

Grouping of Compatible Engines

While the primary focus here is on the QST30 CM552 engines, it is important to note that the Cummins flywheel part 3093712 is also compatible with other similar engine models. This compatibility is due to the standardized design and engineering principles that Cummins employs across its engine lineup. By ensuring that the flywheel fits well with a range of engine models, Cummins maintains a high level of consistency and reliability in its products.

This compatibility allows for easier maintenance and repair processes, as technicians can use the same part across multiple engine types. This standardization not only simplifies inventory management but also ensures that the performance and durability of the flywheel remain consistent across different engine applications.

Role of Part 3093712 Flywheel in Engine Systems

The flywheel, identified by part number 3093712, is an integral component within the engine system, interacting with several other parts to ensure smooth operation and efficient energy transfer.

Interaction with the Clutch System

The flywheel works in conjunction with the clutch system, specifically the pressure plate and clutch disc. When the engine is running, the flywheel rotates, transferring rotational energy from the engine to the transmission via the clutch. This interaction is essential for the seamless engagement and disengagement of the clutch, allowing for smooth gear changes.

Connection to the Crankshaft

The flywheel is bolted to the rear of the crankshaft. This connection enables the flywheel to rotate in sync with the crankshaft, storing rotational energy during the power stroke of the engine’s cycle. This stored energy helps to smooth out the power delivery, reducing vibrations and ensuring consistent engine operation.

Role in the Starter System

During engine start-up, the flywheel engages with the starter motor’s pinion gear. The starter motor rotates the flywheel, which in turn rotates the crankshaft, initiating the engine’s combustion cycle. The flywheel’s inertia assists in cranking the engine over, ensuring a reliable start.

Contribution to the Flywheel Housing

The flywheel is encased within the flywheel housing, which provides structural support and containment. The housing also houses the dual mass flywheel system in some engine configurations, which further reduces NVH (Noise, Vibration, and Harshness) levels by decoupling the engine from the transmission.

Interaction with the Torque Converter (Automatic Transmissions)

In vehicles equipped with automatic transmissions, the flywheel’s role is analogous to that of the flexplate. The torque converter, which replaces the clutch in automatic transmissions, interacts with the flywheel or flexplate to transfer engine power to the transmission. This ensures smooth power delivery and efficient operation of the automatic transmission system.

Influence on the Engine’s Flywheel Effect

The flywheel’s mass and rotational inertia play a significant role in the engine’s flywheel effect. This effect helps maintain rotational energy between power strokes, ensuring the engine runs smoothly even when individual cylinders are not firing. The consistent rotation aids in stabilizing engine RPMs, contributing to overall engine performance and drivability.

Conclusion

The Cummins 3093712 Flywheel is a critical component in the operation of commercial truck engines, designed to store rotational energy and ensure smooth engine performance. Its robust design, compatibility with various engine models, and the benefits it offers in terms of fuel efficiency and longevity make it a valuable part for truck operators and fleet managers. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing its performance and reliability.

-

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.