This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

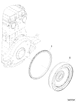

The Cummins 3101528 Flywheel is a component designed to enhance the operation of commercial trucks. Its role is significant in ensuring the smooth and efficient functioning of the engine. This flywheel is engineered to provide reliable performance under demanding conditions, contributing to the overall efficiency and durability of the truck’s engine system.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to smooth out the operation of an engine. It consists of a heavy disc attached to the crankshaft. As the engine runs, the flywheel accumulates kinetic energy, which it then releases to maintain consistent engine speed between power strokes. This mechanism reduces vibrations and ensures a steady power delivery, which is particularly important in the variable load conditions typical of commercial truck operations 1.

Purpose of the 3101528 Flywheel

The Cummins 3101528 Flywheel is specifically designed to play a role in the operation of a truck’s engine. It contributes to engine performance by assisting in the starting process, maintaining smooth idling, and enhancing overall efficiency. The flywheel’s design allows it to effectively store and release energy, which helps in stabilizing the engine’s rotational speed and reducing wear on other components.

Key Features

The Cummins 3101528 Flywheel is characterized by several key features that enhance its performance and durability. Its design incorporates high-strength materials to withstand the rigors of commercial truck use. The flywheel is engineered to provide a balance between weight and inertia, ensuring optimal energy storage and release. Additionally, its construction includes precision machining and balancing to minimize vibrations and ensure smooth operation.

Benefits

Using the Cummins 3101528 Flywheel offers several benefits. It contributes to improved engine performance by ensuring consistent power delivery and reducing engine strain. The flywheel’s durable construction enhances the longevity of the engine components, potentially leading to cost savings over time. Additionally, its efficient design helps in maintaining optimal engine operation under various load conditions 2.

Installation Considerations

Proper installation of the Cummins 3101528 Flywheel is important to ensure its effective functioning. Before installation, it is necessary to ensure that the engine is clean and free of any debris. The use of appropriate tools and following the manufacturer’s guidelines will help in achieving a successful installation. Careful attention to torque specifications and alignment is important to prevent any issues during operation.

Maintenance and Troubleshooting

Regular maintenance practices are important to ensure the longevity and optimal performance of the Cummins 3101528 Flywheel. This includes periodic inspections for signs of wear or damage, ensuring proper lubrication, and checking for any unusual noises or vibrations during operation. Common troubleshooting tips involve addressing issues such as imbalance, which can be rectified by rebalancing the flywheel, and inspecting for any cracks or deformities that may affect its performance 3.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a history of innovation and quality in engine components. The company is known for its commitment to developing reliable and efficient engine solutions, which is reflected in its range of products, including the Cummins 3101528 Flywheel. Cummins’ dedication to quality and performance ensures that its components meet the high standards required for commercial truck applications.

Cummins Flywheel Part 3101528 Compatibility

The Cummins flywheel part number 3101528 is a component in the engine’s operation, ensuring smooth power delivery and efficient engine performance. This flywheel is designed to fit a variety of Cummins engines, providing a reliable and robust solution for various applications. Here is a detailed look at the compatibility of this flywheel with different engine models:

ISX15 Series

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX15 series engines benefit from the 3101528 flywheel due to its ability to handle the high torque and power output characteristic of these models. This flywheel ensures that the engine’s rotational energy is efficiently managed, contributing to the overall performance and longevity of the engine.

QSX15 Series

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 series engines, known for their durability and efficiency, are also compatible with the 3101528 flywheel. This part is engineered to withstand the demanding conditions these engines operate under, providing a stable and reliable connection between the engine and the transmission.

X15 Series

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines, which are designed for heavy-duty applications, are another perfect match for the 3101528 flywheel. This flywheel’s design ensures that it can handle the high stress and frequent use typical of these engines, maintaining optimal performance and reducing the risk of wear and tear.

By ensuring compatibility with these various engine models, the 3101528 flywheel from Cummins provides a versatile and dependable solution for maintaining the efficiency and reliability of the engines it is used with.

Role of Part 3101528 Flywheel in Engine Systems

The flywheel, specifically part 3101528, is an integral component in the operation of an engine system. It is primarily responsible for maintaining rotational energy and ensuring smooth operation between the engine and the transmission.

Interaction with the Engine

When the engine’s pistons move, they generate power that is transferred to the crankshaft. The flywheel is attached to the crankshaft and stores rotational energy during each power stroke. This stored energy helps to smooth out the power delivery, reducing vibrations and ensuring consistent engine operation.

Relationship with the Clutch

In manual transmission vehicles, the flywheel works closely with the clutch. As the driver engages the clutch, the pressure plate compresses the clutch disc against the flywheel, transferring engine power to the transmission. When disengaging the clutch, the flywheel continues to spin, allowing the engine to remain operational while the transmission is disconnected.

Contribution to Starter Motor Function

During engine start-up, the flywheel plays a role in cranking the engine. The starter motor engages with the flywheel’s ring gear, spinning the crankshaft to initiate combustion. The flywheel’s mass aids in this process by providing inertia, making it easier for the starter motor to turn the engine over.

Balance and Vibration Dampening

The flywheel’s design helps to balance the engine by counteracting the reciprocating motion of the pistons. This balance reduces vibrations transmitted to the vehicle’s chassis, contributing to a smoother driving experience. Additionally, the flywheel acts as a vibration dampener, absorbing and dissipating vibrations generated during engine operation.

Support for Ancillary Components

The flywheel also serves as a mounting point for various ancillary components, such as the flexplate in automatic transmissions. This flexplate connects the engine to the torque converter, facilitating the transfer of power to the transmission.

Conclusion

In summary, the Cummins 3101528 Flywheel is a multifaceted component that ensures efficient power transfer, smooth operation, and reduced vibrations within the engine system. Its interaction with the crankshaft, clutch, starter motor, and other components underscores its significance in maintaining overall engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.