This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

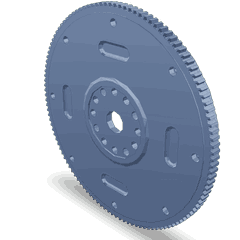

The Cummins 3102962 Flywheel is a critical component in the operation of commercial trucks. It is designed to work in conjunction with the engine to ensure smooth and efficient power transmission. Understanding its purpose and significance can help in maintaining the overall performance and reliability of the vehicle.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and smooths out the power delivery of an engine. It operates on the principle of inertia, resisting changes in rotational speed. Within an engine system, the flywheel plays a role in stabilizing the engine’s rotational speed by storing energy during the power stroke and releasing it during the other strokes 1.

Purpose of the Cummins 3102962 Flywheel

The Cummins 3102962 Flywheel serves multiple functions in the operation of a truck. It interacts with the crankshaft to maintain consistent engine speed and provides the necessary inertia to keep the engine running smoothly between power strokes. Additionally, it engages with the clutch to transmit power from the engine to the transmission, ensuring efficient power delivery 2.

Key Features

The Cummins 3102962 Flywheel is engineered with several key features that enhance its performance. Its design includes a robust housing and a precision-balanced rotor, which contribute to its durability and efficiency. The flywheel is constructed from high-quality materials, such as cast iron, to withstand the rigors of commercial truck operation. Unique attributes, such as its damping capabilities, help reduce vibrations and improve overall engine performance 3.

Benefits

The Cummins 3102962 Flywheel offers several advantages. It contributes to improved engine performance by ensuring smooth power transmission and consistent engine speed. Its durable construction enhances the longevity of the component, while its efficient design helps optimize fuel consumption and reduce wear on other engine components.

Installation Process

Proper installation of the Cummins 3102962 Flywheel is crucial for ensuring its optimal performance. The process involves several steps:

- Ensure the engine is cool and disconnected from the battery.

- Remove the old flywheel, taking care to note its position and any attached components.

- Clean the mating surfaces to ensure a proper fit.

- Install the new flywheel, aligning it with the crankshaft and securing it in place.

- Reattach any components that were removed during the process.

- Reconnect the battery and test the installation for proper function.

Common Issues and Troubleshooting

Flywheels can encounter several common issues, such as excessive wear, warping, or failure to engage properly with the clutch. Potential causes include improper installation, lack of maintenance, or excessive load on the engine. Troubleshooting steps may involve inspecting the flywheel for damage, ensuring proper alignment, and addressing any issues with the clutch or transmission.

Maintenance Tips

Routine maintenance is key to ensuring the longevity and optimal performance of the Cummins 3102962 Flywheel. Regular inspections for signs of wear or damage, proper lubrication of moving parts, and timely replacement of worn components can help prevent issues and extend the lifespan of the flywheel. Additionally, following the manufacturer’s recommended service intervals and guidelines can contribute to the overall health of the engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s commitment to innovation and quality has made it a preferred choice for commercial vehicle manufacturers and operators worldwide.

Compatibility of Flywheel Part 3102962 with Cummins Engines

The Cummins flywheel part number 3102962 is designed to be compatible with a range of Cummins engines, ensuring seamless integration and optimal performance. Here’s a detailed look at the compatibility of this flywheel with the specified engine models:

ISX15 Series

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The flywheel part 3102962 is engineered to fit perfectly with the ISX15 series engines, including the ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101. This compatibility ensures that the flywheel will function effectively with these engines, providing the necessary balance and power transfer.

QSX15 Series

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 series engines, specifically the QSX15 CM2250 ECF and QSX15 CM2350 X105, are also compatible with the flywheel part 3102962. This compatibility is crucial for maintaining the engine’s performance and ensuring that the flywheel can handle the specific demands of these models.

X15 Series

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines, including the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, are designed to work with the flywheel part 3102962. This compatibility ensures that the flywheel can effectively manage the power output and balance requirements of these engines, contributing to overall engine efficiency and longevity.

By ensuring compatibility across these engine models, the flywheel part 3102962 provides a reliable and efficient solution for maintaining the performance and balance of Cummins engines.

Understanding the Role of Part 3102962 Flywheel in Engine Systems

The flywheel, specifically part 3102962, is an integral component in the operation of an engine system. It is primarily responsible for storing rotational energy and ensuring smooth power delivery from the engine to the transmission.

When the engine’s pistons move, they create a rotational force that is transferred to the crankshaft. The flywheel is connected to the crankshaft and helps in maintaining a consistent rotational speed, even when the engine is not firing on all cylinders. This stability is essential for the smooth operation of the engine, especially during the combustion process where power delivery can be inconsistent.

Additionally, the flywheel plays a significant role in the operation of the clutch system. When the clutch is engaged, the flywheel transmits power from the engine to the transmission, allowing the vehicle to move. When the clutch is disengaged, the flywheel continues to rotate, providing a buffer that helps in the smooth re-engagement of the clutch.

Moreover, the flywheel is often used in conjunction with the starter motor during engine start-up. The starter motor engages with the flywheel to crank the engine, initiating the combustion process.

In summary, part 3102962 flywheel is a key component that ensures the efficient and smooth operation of the engine system by storing rotational energy, stabilizing engine speed, facilitating clutch operation, and aiding in engine start-up.

Conclusion

The Cummins 3102962 Flywheel is a vital component in the operation of commercial trucks, ensuring smooth and efficient power transmission. Its robust design, durable construction, and efficient performance contribute to the overall reliability and longevity of the engine system. Proper installation, routine maintenance, and understanding its role in the engine system are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.