This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

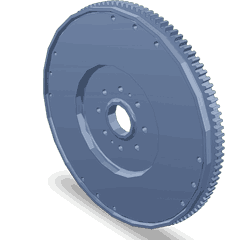

The Cummins 3104135 Flywheel is a critical component in commercial trucks, essential for the engine’s efficient operation. This part stores rotational energy, contributing to the engine’s smooth running and consistent performance. Understanding its function and importance is key to maintaining optimal vehicle performance.

Basic Concepts of a Flywheel

A flywheel is a mechanical device designed to store rotational energy efficiently. It resists changes in rotational speed, providing a smoothing effect on the power delivery from an engine. In an engine system, the flywheel maintains momentum between power strokes, ensuring consistent operation 1.

Purpose of the Cummins 3104135 Flywheel

The Cummins 3104135 Flywheel is integral to a truck’s engine operation. It stores rotational energy during the power stroke and releases it during other strokes, helping to maintain a steady engine speed. This flywheel balances power delivery, reduces vibrations, and aids in the efficient transfer of power to the transmission 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials. It is engineered to withstand the demanding conditions of commercial truck operations. Key features include a precision-balanced design for smooth operation, durable materials for enhanced longevity, and a design that facilitates efficient energy storage and transfer 3.

Benefits

The Cummins 3104135 Flywheel offers several benefits. It contributes to improved engine efficiency by ensuring smooth power delivery and reducing vibrations. Its durable construction enhances the longevity of the component, providing reliable performance over extended periods. Additionally, the flywheel ensures consistent engine operation, contributing to overall vehicle performance 4.

Installation Considerations

Proper installation of the Cummins 3104135 Flywheel is essential for optimal performance. Installation procedures should follow manufacturer guidelines, which may include specific torque settings and the use of appropriate tools. Ensuring the flywheel is correctly aligned and balanced during installation prevents issues such as vibrations or uneven wear.

Troubleshooting Common Issues

Common issues with flywheels can include excessive wear, vibrations, or difficulty in engaging the clutch. Troubleshooting steps for the Cummins 3104135 Flywheel may involve inspecting for signs of wear or damage, ensuring proper alignment and balance, and checking the condition of the clutch system. Addressing these issues promptly maintains the efficiency and reliability of the engine.

Maintenance Tips

Regular maintenance of the Cummins 3104135 Flywheel is important for ensuring longevity and optimal performance. Maintenance tips include periodic inspection for signs of wear or damage, ensuring proper alignment and balance, and following manufacturer recommendations for service intervals. Keeping the flywheel clean and free from contaminants contributes to its efficient operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3104135 Flywheel, which is designed to meet the demanding requirements of commercial truck applications.

Compatibility with Cummins Engines

The 3104135 Flywheel is integral to the operation of the Cummins ISM CM570 and ISM CM570/870 engines. It is designed to work seamlessly with the engine’s crankshaft, ensuring smooth rotational motion and efficient power transfer. The flywheel’s role is critical in maintaining the engine’s balance and stability, which is essential for the overall performance of these engines.

Similarly, the 3104135 Flywheel is also compatible with the Cummins ISM CM876 and ISM11 CM876 SN engines. This part is engineered to fit precisely with the crankshaft of these engines, ensuring that the rotational motion is smooth and efficient. The flywheel’s design is optimized to work with the specific torque and rotational speed characteristics of these engines, contributing to their reliable and powerful performance.

Role of the 3104135 Flywheel in Engine Systems

The 3104135 Flywheel is an integral component within the engine system, facilitating smooth operation and efficient energy transfer. When the engine’s pistons move, they generate rotational force, which is transferred to the flywheel via the crankshaft. This rotational force is then stored as kinetic energy within the flywheel.

As the engine cycles through its power strokes, the flywheel’s stored energy helps to maintain consistent rotational speed, smoothing out the power delivery to the transmission. This is particularly important during the engine’s idle phases or when the vehicle is decelerating, as the flywheel ensures that the engine does not stall.

Additionally, the flywheel plays a significant role during the clutch engagement process. When the clutch is disengaged, the flywheel continues to spin, allowing the engine and transmission to operate independently. Upon re-engagement, the flywheel’s stored energy assists in transferring power from the engine to the transmission, ensuring a seamless transition.

Conclusion

In summary, the 3104135 Flywheel is a key element in the engine system, contributing to stable engine operation, efficient energy transfer, and smooth clutch engagement. Its role in storing and releasing kinetic energy is essential for the overall performance and drivability of the vehicle.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.