This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

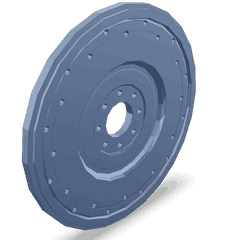

The Cummins 3281524 Flywheel is a component designed for use in heavy-duty trucks. It plays a role in the engine system by aiding in the smooth operation and efficient performance of the vehicle. Understanding its function and significance can provide valuable insights into the overall operation of heavy-duty trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing energy during acceleration and releasing it during deceleration. This mechanism smooths out the power delivery from the engine, ensuring a more stable and efficient operation. In the context of heavy-duty trucks, flywheels play a role in managing the engine’s rotational energy, contributing to both performance and fuel efficiency 1.

Purpose of the Cummins 3281524 Flywheel

The Cummins 3281524 Flywheel is specifically engineered to enhance the operation of heavy-duty trucks. It contributes to engine performance by storing rotational energy, which helps to stabilize the engine’s RPM during the combustion process. This stabilization leads to smoother engine operation and can improve fuel efficiency. Additionally, the flywheel aids in the engagement of the clutch, facilitating smoother gear changes and reducing wear on the transmission system 2.

Key Features

The Cummins 3281524 Flywheel is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials, such as cast iron or steel, which provide strength and resilience under the demanding conditions of heavy-duty truck operation. The flywheel’s balanced weight distribution ensures smooth operation, while its precise machining contributes to accurate fitment and function within the engine system. These features collectively enhance the flywheel’s ability to store and release rotational energy efficiently, supporting optimal engine performance 3.

Benefits

Utilizing the Cummins 3281524 Flywheel offers several benefits for heavy-duty truck operators. Improved engine efficiency is one of the primary advantages, as the flywheel’s design contributes to smoother engine operation and potentially better fuel economy. Enhanced durability is another significant benefit, with the flywheel’s robust construction allowing it to withstand the rigors of heavy-duty use. Over time, these factors can lead to potential cost savings, as the flywheel’s longevity and efficiency may reduce the need for frequent replacements or repairs.

Installation and Compatibility

Proper installation of the Cummins 3281524 Flywheel is crucial for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines for installation, which may include specific torque settings and alignment procedures. Compatibility with various truck models and engine types should be verified to ensure the flywheel is suitable for the intended application. This step is vital for maintaining the integrity of the engine system and ensuring the flywheel operates as designed.

Maintenance and Troubleshooting

Maintaining the Cummins 3281524 Flywheel is key to ensuring its optimal performance and longevity. Regular inspections for signs of wear or damage can help identify issues before they become critical. Cleaning the flywheel and its mating surfaces during maintenance can prevent contamination that might affect its operation. Common issues that may arise include uneven wear or damage to the flywheel’s surface, which can affect its ability to store and release rotational energy efficiently. Troubleshooting these issues may involve rebalancing the flywheel or, in severe cases, replacement.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. Founded in 1919, Cummins has built a legacy of quality, innovation, and reliability. The company’s commitment to engineering excellence is evident in its wide range of products, including engines, filtration systems, and aftermarket parts. Cummins’ dedication to quality and customer satisfaction has made it a trusted name in the industry, with a global presence and a strong focus on sustainability and technological advancement.

Compatibility with Cummins Engines

4B3.9 Engine

The 3281524 flywheel is engineered to integrate perfectly with the 4B3.9 engine. This engine, known for its robust design, benefits from the flywheel’s ability to store and release energy efficiently, contributing to the engine’s smooth operation and longevity.

6B5.9 Engine

Similarly, the 3281524 flywheel is also compatible with the 6B5.9 engine. This engine, which is part of Cummins’ lineup, is designed for heavy-duty applications. The flywheel’s role in this engine is crucial, as it helps in maintaining consistent engine speed and power output, essential for the demanding tasks these engines are built to handle.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines share a commonality in their requirement for a high-quality flywheel like the 3281524. This part’s design ensures it meets the specific needs of these engines, whether for light to medium-duty or heavy-duty applications. The compatibility of the 3281524 flywheel with these engines underscores its versatility and importance in Cummins’ engine lineup.

Understanding the Role of Part 3281524 Flywheel in Engine Systems

The flywheel, identified by part number 3281524, is an integral component within the engine system, facilitating a seamless operation between various mechanical parts. Its primary function is to store rotational energy and deliver it as needed, ensuring smooth engine operation.

Interaction with the Crankshaft

The flywheel is directly connected to the crankshaft via a series of bolts. This connection allows the flywheel to rotate in sync with the crankshaft, storing kinetic energy during the power stroke and releasing it during the other strokes (intake, compression, and exhaust). This energy transfer helps maintain engine momentum and stability.

Engagement with the Clutch

In manual transmission vehicles, the flywheel works in conjunction with the clutch. When the clutch pedal is depressed, the pressure plate disengages from the flywheel, allowing the driver to shift gears without interrupting the engine’s rotation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission.

Contribution to the Starter Motor

During engine start-up, the flywheel engages with the starter motor’s pinion gear. The starter motor rotates the flywheel, which in turn rotates the crankshaft, initiating the combustion process. This interaction is essential for the engine to transition from a stationary state to operational mode.

Balance and Vibration Reduction

The flywheel’s mass and design contribute to balancing the engine. By counteracting the reciprocating motion of the pistons, it reduces vibrations and ensures a smoother running engine. This balance is particularly important in inline engines where the forces are not inherently balanced.

Support for Ancillary Components

The flywheel often serves as a mounting point for other engine components, such as the flexplate in automatic transmissions or various sensors that monitor engine performance. Its robust structure provides a stable base for these additional elements, ensuring their accurate function and durability.

Conclusion

In summary, the Cummins 3281524 Flywheel plays a multifaceted role in engine systems, enhancing performance, ensuring smooth operation, and supporting various interconnected components. Its design and features contribute to the efficient and reliable operation of heavy-duty trucks, making it a critical component in the engine’s operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.