This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

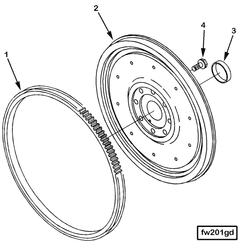

The Cummins 3328886 Flywheel is a critical component for heavy-duty trucks, designed to enhance engine performance and ensure smooth operation. This part contributes to the efficient functioning of the engine by stabilizing rotational speed and facilitating power transmission.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and smooths power delivery in an engine 1. It operates on the principle of inertia, maintaining rotational speed during acceleration and deceleration cycles. Within an engine system, the flywheel stabilizes the engine’s rotational speed, ensuring consistent power output and efficient operation. It also engages with the starter motor during engine start-up and facilitates power transmission to the drivetrain.

Purpose of the 3328886 Flywheel

The 3328886 Flywheel is engineered to enhance the performance of heavy-duty truck engines. It ensures smooth power delivery and reduces vibrations, providing the necessary balance and stability for optimal performance under various operating conditions 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, constructed to withstand the demanding conditions of heavy-duty truck operation. Notable features include its durable composition, precise engineering, and design elements that enhance performance and longevity. These characteristics make it a preferred choice for heavy-duty applications.

Benefits

Utilizing the 3328886 Flywheel in heavy-duty trucks offers several advantages. It contributes to improved engine efficiency, ensuring smooth and effective operation. The flywheel’s durable construction enhances the engine’s reliability and longevity, even under strenuous conditions. Additionally, it supports better performance across a range of operating scenarios, making it a valuable component for heavy-duty truck engines.

Installation Considerations

Proper installation of the 3328886 Flywheel is essential for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines closely, paying attention to alignment, torque specifications, and any specific installation procedures. Correct installation ensures the flywheel functions as intended and contributes to the overall efficiency and reliability of the engine.

Troubleshooting Common Issues

Flywheels, including the 3328886 model, may encounter issues such as excessive wear, noise, or failure to engage properly with the starter motor. Troubleshooting these problems involves a systematic approach to diagnosis, which may include inspecting for wear and tear, checking alignment, and ensuring all connections are secure. Addressing these issues promptly can prevent further damage and ensure the flywheel continues to operate efficiently.

Maintenance Tips

Regular maintenance of the 3328886 Flywheel is key to ensuring its continued reliable performance. This includes routine inspections for signs of wear or damage, cleaning to remove any debris that may affect operation, and making any necessary adjustments. Adhering to a maintenance schedule helps in identifying potential issues early, thereby extending the lifespan of the flywheel and ensuring the engine operates smoothly.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the production of automotive components, particularly for heavy-duty trucks. Established with a commitment to quality and innovation, Cummins has built a legacy of producing reliable and high-performance parts. The company’s expertise in engine technology and component manufacturing underscores the quality and reliability of the 3328886 Flywheel 3.

Compatibility with Cummins Engines

The flywheel part number 3328886 is designed to fit seamlessly with several Cummins engine models. This part is integral to the engine’s operation, ensuring smooth power delivery and efficient performance. Here is a detailed look at its compatibility with specific Cummins engines:

L10 GAS Engine

The L10 GAS engine is a robust and reliable option for various applications. The 3328886 Flywheel is engineered to integrate perfectly with this engine, providing the necessary balance and rotational inertia to maintain engine stability and performance.

M11 CELECT and M11 CELECT PLUS Engines

The M11 CELECT and M11 CELECT PLUS engines are advanced models known for their efficiency and power. The 3328886 Flywheel is specifically designed to fit these engines, ensuring optimal performance and durability. This part is crucial for the smooth operation of these engines, contributing to their reputation for reliability and efficiency.

Grouping of Engines

When considering the compatibility of the 3328886 Flywheel, it is useful to group the engines based on their design and application. The L10 GAS engine, while robust, is typically used in applications requiring high power output. In contrast, the M11 CELECT and M11 CELECT PLUS engines are more advanced and are often found in applications where efficiency and lower emissions are critical. Despite these differences, the 3328886 Flywheel is designed to fit all these engines, ensuring a consistent and reliable performance across different models.

Role of the 3328886 Flywheel in Engine Systems

The 3328886 Flywheel is an integral component within the engine system, facilitating smooth operation and efficient energy transfer. It is primarily responsible for storing rotational energy and ensuring consistent power delivery between the engine’s power strokes.

Interaction with Engine Components

-

Crankshaft: The flywheel is bolted to the rear of the crankshaft. As the engine operates, the flywheel rotates with the crankshaft, storing kinetic energy during each power stroke. This stored energy helps maintain the engine’s momentum between strokes, ensuring a steady rotational speed.

-

Clutch System: In manual transmission vehicles, the flywheel works in conjunction with the clutch. When the clutch is engaged, the flywheel transmits power from the engine to the transmission. During gear changes, the clutch disengages, allowing the flywheel to continue spinning independently, which smooths out the transition between gears.

-

Starter Motor: During engine start-up, the starter motor engages with the flywheel to crank the engine. The flywheel’s mass provides the necessary inertia to start the engine smoothly and efficiently.

-

Dual Mass Flywheel (DMF) Systems: In vehicles equipped with a DMF, the 3328886 Flywheel plays a role in reducing NVH (Noise, Vibration, and Harshness). The DMF consists of two masses connected by a series of springs, which absorb torsional vibrations from the engine, resulting in a quieter and more comfortable driving experience.

-

Flywheel Housing: The flywheel is encased within the flywheel housing, which protects it from external elements and contains any potential debris generated during operation.

-

Pressure Plate: In the clutch assembly, the flywheel interacts directly with the pressure plate. The pressure plate applies force to the clutch disc, which in turn connects to the flywheel, transmitting power to the transmission.

-

Flywheel Ring Gear: The flywheel incorporates a ring gear that meshes with the starter motor’s pinion gear during engine start-up. This gear arrangement ensures reliable and consistent engine cranking.

By understanding the flywheel’s interactions with these components, engineers and mechanics can better appreciate its significance in maintaining engine performance and drivability.

Conclusion

The Cummins 3328886 Flywheel is a vital component for heavy-duty truck engines, ensuring smooth operation, efficient energy transfer, and reliable performance. Its robust design, precise engineering, and compatibility with various Cummins engines make it an essential part for maintaining engine stability and efficiency. Regular maintenance and proper installation are crucial for maximizing the lifespan and performance of this part.

-

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Hannes Hick, Klaus Kupper, and Helfried Sorger, Systems Engineering for Automotive Powertrain Development, Springer, 2021.

↩ -

Cummins Inc., Owners Manual for QSB6.7 CM2250 EC (173 HP or Below), Bulletin Number 2883623.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.