This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

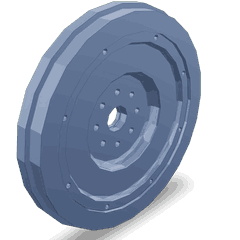

The Cummins 3415350 Flywheel is a critical component designed for commercial trucks, essential for maintaining consistent engine operation under varying load conditions. This part stores rotational energy and smooths power delivery from the engine to the transmission, ensuring efficient and reliable performance in commercial trucking applications.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy, consisting of a heavy disc attached to a rotating shaft. It resists changes in rotational speed, stabilizing the engine’s rotational speed by storing energy during the power stroke and releasing it during other strokes. This ensures smoother operation and aids in the starting process by engaging with the starter motor to initiate engine rotation 1.

Purpose of the Cummins 3415350 Flywheel

The Cummins 3415350 Flywheel is engineered to enhance the performance and reliability of commercial truck engines. It interacts with the engine’s crankshaft, clutch, and transmission system, storing rotational energy to maintain consistent engine speed and reduce vibrations, ensuring a smoother driving experience 2.

Key Features

This Cummins part is characterized by robust construction, capable of withstanding high stresses and loads in commercial truck applications. It is made from high-quality materials, typically a combination of steel and cast iron, providing strength and durability. Precision machining ensures accurate fitment and optimal performance within the engine system 3.

Benefits

The 3415350 Flywheel offers several benefits, including smooth engine vibrations, consistent power delivery, enhanced drivability, and reduced wear on other engine components. Its durable construction ensures long-term reliability and reduced maintenance requirements.

Installation Process

Proper installation of the 3415350 is crucial for optimal performance and longevity. The process involves:

- Ensuring the engine is properly supported and the transmission is disconnected.

- Removing the old flywheel, noting its orientation and mounting details.

- Cleaning the mating surfaces on the crankshaft and transmission.

- Installing the new flywheel, aligning it correctly with the crankshaft and transmission.

- Securing the flywheel using appropriate bolts and torque specifications.

- Reconnecting the transmission and performing a final inspection to ensure proper installation and alignment.

Maintenance Tips

To ensure peak performance, regular maintenance is recommended:

- Inspect the flywheel for wear or damage during routine engine maintenance.

- Ensure proper alignment and fitment to prevent excessive wear on the crankshaft and transmission.

- Clean the flywheel and mating surfaces to remove debris or contaminants.

- Follow the manufacturer’s recommended torque specifications during installation.

Troubleshooting Common Issues

Common issues may include vibrations, difficulty starting the engine, or unusual noises. To address these:

- Inspect the flywheel for cracks or damage.

- Check alignment and fitment to ensure proper installation.

- Verify that the clutch is engaging correctly.

- Ensure the starter motor is functioning properly.

Compatibility and Applications

The 3415350 is designed for specific applications within the commercial truck industry, compatible with certain Cummins engine models and series, ensuring optimal performance and reliability.

Cummins Overview

Cummins Inc. is a global power leader with a history spanning over a century. The company’s commitment to excellence is reflected in its extensive range of engine components, including the 3415350, designed to meet the demanding requirements of commercial trucking applications.

Cummins Flywheel 3415350 Compatibility

The 3415350 is a critical component in the engine’s operation, ensuring the smooth transfer of power from the engine to the transmission. It is designed to fit a variety of Cummins engines, providing a reliable interface between the engine and the transmission system.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B6.7 CM2670 B164C

- ISL9.5 CM2880 L138

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9.3 L105

- QSB4.5 CM850(CM2850)

- QSB6.7 CM850(CM2850)

- QSB7 CM2880 B117

- QSC8.3 CM2880 C102

- QSL8.9 CM2150 L141

- QSL9 CM850(CM2850)

- QSL9.3 CM2880 L113

Grouping of Compatible Engines

-

Smaller Engines:

- 4B3.9

- 6B5.9

- 6C8.3

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

- L9.3 L105

- QSB4.5 CM850(CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM850(CM2850)

-

Larger Engines:

- B6.7 CM2670 B164C

- ISL9.5 CM2880 L138

- QSB6.7 CM850(CM2850)

- QSB7 CM2880 B117

- QSC8.3 CM2880 C102

- QSL9.3 CM2880 L113

This flywheel is engineered to meet the demands of both smaller and larger engines, ensuring compatibility across a wide range of applications.

Role of Part 3415350 Flywheel in Engine Systems

The flywheel, specifically part 3415350, is integral to the smooth operation of an engine system. It is designed to work in harmony with several key components to ensure efficient energy transfer and consistent engine performance.

Interaction with the Crankshaft

The flywheel is bolted to the rear of the crankshaft. As the engine’s pistons move up and down, they impart rotational force to the crankshaft. The flywheel stores this rotational energy and releases it smoothly, helping to maintain the engine’s momentum between power strokes. This interaction is essential for the engine’s continuous operation, especially during the phases when the pistons are not actively generating power.

Relationship with the Clutch System

In manual transmission vehicles, the flywheel works closely with the clutch system. When the clutch pedal is depressed, the pressure plate disengages from the flywheel, allowing the driver to change gears without interrupting the engine’s rotation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission. The flywheel’s mass and inertia are vital in this process, ensuring a seamless transfer of power.

Contribution to Vibration Dampening

The flywheel also plays a significant role in reducing vibrations within the engine system. Its substantial mass helps to smooth out the pulsations caused by the reciprocating motion of the pistons. This dampening effect is particularly important in inline engines, where the firing intervals can create significant vibrations if not properly managed.

Support for Starter Motor Engagement

During engine start-up, the flywheel provides a surface for the starter motor’s pinion gear to engage. The teeth on the flywheel’s outer rim mesh with the pinion gear, allowing the starter motor to turn the engine over. This engagement is a critical step in the starting process, ensuring that the engine begins its cycle of operation.

Influence on Engine Balance

The flywheel’s design and mass distribution contribute to the overall balance of the engine. Proper balancing is essential to prevent excessive wear on engine components and to ensure smooth operation. The flywheel helps to counteract the forces generated by the pistons and crankshaft, promoting a stable and efficient engine performance.

Conclusion

The Cummins 3415350 Flywheel is a multifaceted component that interacts with various engine systems to enhance performance, ensure smooth operation, and maintain balance. Its role extends beyond simple energy storage, influencing clutch engagement, vibration dampening, and engine start-up.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.