This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

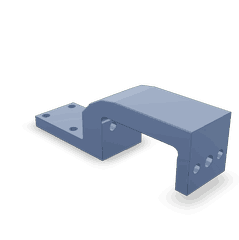

The Flywheel Housing Support, identified by Part #3643951, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly in heavy-duty trucks. This part is integral to the engine assembly, contributing to the overall stability and performance of the vehicle.

Basic Concepts

Flywheel housing supports are designed to secure the flywheel within the engine assembly. They facilitate the connection between the engine and the transmission, ensuring smooth power transfer. These supports interact closely with other engine components, including the crankshaft and clutch system, to maintain alignment and reduce vibrations 1.

Purpose and Function

The Flywheel Housing Support (Part #3643951) plays a role in the operation of a truck by providing a stable mounting point for the flywheel. This stability is crucial for maintaining engine balance and minimizing vibrations, which can otherwise lead to wear and tear on other engine components. Additionally, it contributes to the efficient transfer of power from the engine to the transmission, enhancing overall vehicle performance 2.

Key Features

The Flywheel Housing Support is constructed from durable materials, typically cast iron or high-strength steel, to withstand the rigors of heavy-duty use. Its design includes precise mounting points and alignment features to ensure proper fitment and function within the engine assembly. Unique attributes such as integrated damping features may also be present to further reduce vibrations and enhance engine smoothness 3.

Benefits

The advantages of using the Flywheel Housing Support include improved engine reliability due to its robust construction and precise fit. Reduced vibration contributes to a smoother operation, which can extend the lifespan of connected components. Enhanced durability ensures that the part can withstand the demanding conditions typical of heavy-duty truck applications 4.

Installation Process

Installing the Flywheel Housing Support requires careful attention to detail. The process involves aligning the support with the engine block, securing it in place using the appropriate fasteners, and ensuring that all connections are tight and properly torqued. It is important to follow manufacturer guidelines to avoid over-tightening, which can lead to damage, or under-tightening, which can result in instability.

Common Issues and Troubleshooting

Frequent problems with Flywheel Housing Supports may include misalignment, which can cause vibrations or difficulty in shifting gears. Troubleshooting often involves checking the alignment of the support and ensuring that all fasteners are properly tightened. In some cases, replacing worn or damaged components may be necessary to restore optimal function.

Maintenance Tips

To ensure the longevity and optimal performance of the Flywheel Housing Support, routine maintenance practices should be followed. This includes regular inspections for signs of wear or damage, ensuring that all fasteners remain tight, and addressing any vibrations or unusual noises promptly. Keeping the engine clean and free of debris can also contribute to the overall health of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. Their product range includes engines and components for on-highway, off-highway, and stationary applications, serving a variety of industries worldwide.

Role of Part 3643951 Flywheel Housing Support in Engine Systems

The 3643951 Flywheel Housing Support is an integral component in the assembly and operation of engine systems, particularly in the context of the support and rear engine components. This part ensures the stable mounting of the flywheel, which is essential for the smooth operation of the engine.

Integration with Support Components

The Flywheel Housing Support interfaces directly with the engine’s support structure. It provides a robust framework that secures the flywheel in place, allowing it to operate efficiently without undue movement. This stability is vital for maintaining the precision of the engine’s rotational dynamics, which directly influences the overall performance and longevity of the engine.

Interaction with Rear Engine Components

In the rear section of the engine, the 3643951 component plays a significant role in aligning and supporting the flywheel. This alignment is crucial for the proper engagement of the flywheel with the clutch system, ensuring seamless power transmission from the engine to the transmission system. The support offered by this part helps in reducing wear and tear on both the flywheel and the clutch, contributing to the engine’s reliability and efficiency.

Enhanced Engine Performance

By providing a solid mounting point for the flywheel, the 3643951 Flywheel Housing Support contributes to the engine’s ability to maintain consistent RPMs, which is essential for optimal fuel efficiency and power delivery. Its design and placement within the engine system are tailored to withstand the high stresses and vibrations inherent in engine operation, thereby enhancing the engine’s overall performance and durability.

Conclusion

Understanding the role of the 3643951 Flywheel Housing Support within the engine system highlights its importance in maintaining the structural integrity and operational efficiency of the engine. Its interaction with both support and rear engine components underscores its significance in the complex dynamics of engine functionality.

-

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Carroll, D.R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.