This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3655407 Flywheel Housing is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by housing and supporting the flywheel, which is integral to the engine’s function. This housing ensures the smooth operation of the engine by maintaining balance and facilitating efficient gear transitions.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, a heavy rotating disc that stores rotational energy. This housing plays a role in the engine system by providing a secure environment for the flywheel to operate. It interacts with other components such as the clutch and transmission, ensuring that power is efficiently transferred from the engine to the drivetrain 1.

Purpose of the 3655407 Flywheel Housing

This Cummins part is designed to play a role in the operation of a truck by supporting the flywheel. It contributes to maintaining engine balance, which is vital for smooth operation. Additionally, it facilitates smooth gear transitions by providing a stable mounting point for the flywheel, which is crucial for the efficient operation of the clutch and transmission system 2.

Key Features

The design and construction of the 3655407 include a robust material composition that ensures structural integrity. It is engineered with precision to accommodate the flywheel and other related components. Unique design elements may include reinforced sections to withstand the stresses of heavy-duty applications, enhancing its performance and longevity.

Benefits

The 3655407 offers several advantages, including improved engine efficiency due to its precise design and material choice. Its durability is enhanced by the robust construction, making it suitable for heavy-duty applications. Reliability is also a key benefit, as the housing is designed to withstand the rigors of commercial truck operation.

Installation Process

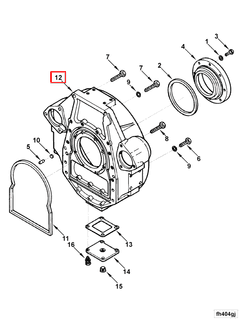

Proper installation of this part involves several steps to ensure optimal performance. Necessary tools and preparation steps include ensuring the engine is clean and free of debris. Alignment procedures are critical to ensure that the housing is correctly positioned relative to the flywheel and other components. Following manufacturer guidelines during installation will help maintain the integrity and function of the housing.

Common Issues and Troubleshooting

Typical problems associated with flywheel housings can include leaks, cracks, or misalignment. Troubleshooting these issues involves a systematic approach to diagnose the problem. For leaks, checking seals and gaskets is important. Cracks may require a visual inspection and, if found, professional repair or replacement. Misalignment issues can often be resolved by re-checking the installation process and making necessary adjustments.

Maintenance Tips

Routine maintenance practices can help prolong the lifespan of the 3655407. Regular inspection intervals should be observed to check for signs of wear or damage. Cleaning procedures, such as removing dirt and grime, can prevent buildup that may lead to performance issues. Knowing when to consider replacement is also important, typically when significant wear or damage is observed.

Compatibility and Applications

The 3655407 is designed for specific types of engines and truck models. It is important to consult compatibility information to ensure it is suitable for the intended application. Specific application notes or considerations may include engine size, truck model, and any unique requirements of the vehicle’s drivetrain system.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of high-quality engine components. With a history of innovation and reliability, Cummins products, including the 3655407, are designed to meet the demanding requirements of commercial trucking. The company’s reputation for quality and performance underscores the reliability of its components in heavy-duty applications.

Compatibility of Flywheel Housing Part 3655407

The Cummins flywheel housing part number 3655407 is designed to fit seamlessly with several engine models. This part is crucial for the proper functioning of the engine’s flywheel mechanism, ensuring smooth operation and efficient power transfer.

K19 Engines

The K19 engine series is one of the primary beneficiaries of the 3655407 flywheel housing. This part is engineered to match the specific design and requirements of the K19 engines, ensuring optimal performance and durability. The compatibility of this flywheel housing with the K19 engines makes it a reliable choice for maintenance and repairs.

Grouping of Compatible Engines

While the K19 series is a primary focus, it is essential to recognize that the 3655407 flywheel housing is also compatible with other Cummins engines that share similar design parameters and specifications. This part’s versatility allows it to be used across multiple engine models, providing a standardized solution for various applications.

The compatibility of the 3655407 flywheel housing with the K19 engines and other similar models underscores its importance in maintaining the integrity and efficiency of the engine’s flywheel system.

Conclusion

The 3655407 Flywheel Housing is an integral component in the assembly and operation of engine systems. It serves as the primary mounting point for the flywheel, which is a heavy, rotating disk designed to smooth out the power delivery of the engine by storing rotational energy. The flywheel housing is engineered to provide a secure and stable environment for the flywheel, ensuring that it operates efficiently and reliably.

When integrated into the engine system, the flywheel housing interfaces with several key components. It is bolted to the engine block, creating a solid foundation for the flywheel to rotate. This connection is vital for maintaining the structural integrity of the engine, as it must withstand the considerable forces generated during operation.

The flywheel itself is connected to the crankshaft via the flywheel bolts, which pass through the flywheel housing. This arrangement allows the flywheel to rotate in sync with the crankshaft, facilitating the transfer of power from the engine to the transmission. The precise alignment and secure fit provided by the flywheel housing are essential for the smooth operation of this power transfer.

Additionally, the flywheel housing interacts with the clutch system. In manual transmissions, the pressure plate and clutch disc are mounted to the flywheel, and the housing provides the necessary support for these components. The housing must be designed to accommodate the clutch alignment tool, ensuring that the clutch components are properly aligned during installation and maintenance.

In automatic transmissions, the flywheel housing still plays a significant role, although the setup differs. Here, the housing supports the flexplate, which performs a similar function to the flywheel in manual transmissions. The flexplate is connected to the torque converter, and the housing ensures that this connection is stable and secure.

Overall, the flywheel housing is a fundamental component that ensures the proper functioning and durability of the engine system by providing a robust and precise interface for the flywheel and related components 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.