This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

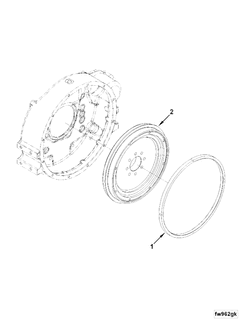

The Cummins 3864088 Flywheel is a component designed for use in heavy-duty trucks. It plays a significant role in the operation of these vehicles by contributing to the smooth and efficient functioning of the engine. Understanding its purpose and functionality is key to appreciating its importance in the overall performance of heavy-duty trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device specifically designed to efficiently store rotational energy. It operates by resisting changes in rotational speed, providing a stabilizing effect on the engine’s operation. In an engine, the flywheel maintains consistent rotational energy, which is important for the smooth operation of the vehicle. It also engages with the starter motor during the starting process, helping to initiate engine rotation 1.

Purpose of the 3864088 Flywheel

The 3864088 Flywheel is integral to the operation of a truck’s engine. It functions to smooth out the power delivery from the engine’s cylinders, ensuring a consistent rotational speed. This smoothing effect is particularly important in diesel engines, where the power delivery can be less uniform compared to gasoline engines. Additionally, the flywheel aids in the starting process by engaging with the starter motor, facilitating the initial rotation of the engine 2.

Key Features

The 3864088 Flywheel is characterized by its robust design and the materials used in its construction. It is typically made from high-strength materials to withstand the rigors of heavy-duty use. The design includes features that enhance its performance, such as a balanced weight distribution to minimize vibrations and a durable surface to resist wear 3.

Benefits

The use of the 3864088 Flywheel in heavy-duty trucks offers several benefits. It contributes to improved engine efficiency by ensuring smooth power delivery. Its durable construction enhances the longevity of the component, providing reliable performance under demanding conditions. Additionally, the flywheel’s design helps in reducing engine vibrations, leading to a more stable and comfortable driving experience.

Installation Process

Installing the 3864088 Flywheel requires careful attention to detail. The process involves aligning the flywheel with the engine and transmission, ensuring that it is properly seated and secured. Tools such as torque wrenches are necessary to tighten the flywheel bolts to the manufacturer’s specified torque settings. It is also important to check the alignment of the flywheel with the starter motor to ensure proper engagement during starting.

Common Issues and Troubleshooting

Common issues with the 3864088 Flywheel may include wear and tear, imbalance, or failure symptoms such as unusual noises or vibrations. Troubleshooting these issues involves inspecting the flywheel for signs of damage or wear, checking the alignment, and ensuring that all bolts are tightened to the correct specifications. In some cases, rebalancing or replacing the flywheel may be necessary to resolve these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3864088 Flywheel, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the flywheel to remove any debris, and checking the alignment and torque of the mounting bolts. Following the manufacturer’s guidelines for maintenance and replacement can help prevent issues and ensure the flywheel continues to function effectively.

Compatibility and Applications

The 3864088 Flywheel is designed for specific types of engines and truck models. It is important to verify compatibility with the specific engine and transmission configuration to ensure proper fit and function. The flywheel is intended for use in applications where heavy-duty performance and reliability are required.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines and components designed to meet the demands of various applications, from on-highway to off-highway and industrial uses.

Cummins Flywheel Part 3864088 Compatibility

The Cummins flywheel part number 3864088 is designed to fit a variety of Cummins engines, ensuring compatibility across different models. Here is a detailed breakdown of the engines with which this flywheel is compatible:

Compatible Engines

- 4B3.9

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

Grouping of Compatible Engines

The flywheel part 3864088 is engineered to fit within the following groups of engines:

-

QSB Series:

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

-

Other Models:

- 4B3.9

This part is designed to ensure seamless integration and optimal performance across these engine models, providing a reliable solution for various applications.

Role of Part 3864088 Flywheel in Engine Systems

The flywheel, specifically part 3864088, is an integral component in the operation of engine systems, serving multiple functions that contribute to the overall performance and efficiency of the engine.

Energy Storage and Smooth Operation

One of the primary roles of the flywheel is to store rotational energy. When the engine’s pistons move, they generate power that is transferred to the crankshaft. The flywheel absorbs this energy during the power stroke and releases it during the other strokes (intake, compression, and exhaust), ensuring a smooth and consistent rotational speed. This helps in maintaining engine stability and reducing vibrations 1.

Clutch Engagement

In manual transmission systems, the flywheel plays a key role in the clutch mechanism. When the clutch pedal is depressed, the pressure plate is moved away from the flywheel, disconnecting the engine from the transmission. Releasing the pedal allows the pressure plate to engage with the flywheel, transferring engine power to the transmission and ultimately to the wheels. The flywheel’s surface must be smooth and free of imperfections to ensure a proper engagement 2.

Starter Motor Interaction

During engine start-up, the flywheel interacts with the starter motor. The starter motor’s pinion gear engages with the flywheel’s ring gear to crank the engine. The flywheel’s design must accommodate this interaction without causing damage to either component 3.

Balancing the Engine

The flywheel also contributes to the engine’s balance. Its mass helps counteract the reciprocating motion of the pistons, reducing the overall vibration and wear on engine components. This balancing act is essential for the longevity and smooth operation of the engine.

Torque Conversion

In some engine systems, particularly those with automatic transmissions, the flywheel’s role is somewhat analogous to the torque converter. While the torque converter uses fluid dynamics to transfer power, the flywheel uses mechanical means. The consistent rotational inertia provided by the flywheel helps in maintaining a stable power delivery to the transmission.

Thermal Management

The flywheel also plays a part in thermal management within the engine bay. Its mass absorbs heat generated during engine operation, helping to dissipate this heat gradually. This can contribute to more stable engine temperatures and improved overall performance.

Conclusion

In summary, the 3864088 Flywheel is a multifaceted component that enhances the functionality and efficiency of engine systems through energy storage, smooth operation, clutch engagement, starter motor interaction, engine balancing, torque conversion, and thermal management. Its robust design and durable construction make it suitable for heavy-duty applications, ensuring reliable performance and longevity in demanding conditions.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ ↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ ↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.