This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

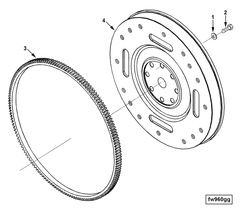

The Cummins 3906800 Flywheel is a critical component designed for heavy-duty truck engines, significantly contributing to the efficient operation of these robust machines. Its primary function is to store rotational energy, ensuring smooth engine operation and enhancing overall performance and reliability.

Basic Concepts of a Flywheel

A flywheel is a mechanical device designed to store rotational energy efficiently. It resists changes in rotational speed, providing stability and consistency in engine operation. Within the powertrain system, the flywheel connects the engine to the transmission, ensuring seamless power transfer and maintaining engine momentum between power strokes 1.

Purpose of the Cummins 3906800 Flywheel

The Cummins 3906800 Flywheel serves multiple functions in truck operation. It stores rotational energy, smoothing power delivery from the engine’s cylinders and maintaining engine speed during periods between power strokes. This ensures consistent and stable engine operation. Additionally, the flywheel engages with the starter motor to initiate engine rotation during the starting process 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, contributing to its performance and durability. It features a balanced mass for smooth operation and reduced vibrations. Constructed from durable materials, it withstands high stresses and temperatures in heavy-duty applications. Its design includes provisions for easy installation and maintenance, enhancing practicality in field applications 3.

Benefits

The Cummins 3906800 Flywheel offers several benefits that contribute to the overall efficiency and performance of heavy-duty trucks. By storing rotational energy, it maintains consistent engine speed, improving engine efficiency. The smooth operation enhances drivability, making the truck more responsive and easier to operate. Efficient energy storage and transfer can also contribute to potential fuel savings, making it valuable for fleet operators aiming to optimize fuel consumption 4.

Installation Considerations

Proper installation of the Cummins 3906800 Flywheel is crucial for optimal performance and longevity. Installation procedures should follow manufacturer guidelines to ensure correct alignment and secure fitting. Special tools may be required, and it is important to verify that all mating surfaces are clean and free from debris to prevent operational issues.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3906800 Flywheel is important for continued reliable operation. This includes checking for signs of wear or damage, ensuring all fasteners are secure, and verifying proper alignment with the engine and transmission. Common issues include uneven wear, leading to vibrations, and surface damage affecting engagement with the starter motor or transmission. Troubleshooting typically involves a thorough inspection and, if necessary, replacement or repair of affected components.

Performance Enhancements

The Cummins 3906800 Flywheel can enhance overall engine performance by providing a stable platform for power delivery. Its ability to store and release rotational energy can improve torque and power delivery, making the engine more responsive under load. This is particularly beneficial in heavy-duty applications where consistent and reliable power is crucial.

Compatibility and Applications

The Cummins 3906800 Flywheel is designed for use in various heavy-duty truck engines, offering versatility across different applications. Its compatibility with a range of engine models makes it a popular choice for fleet operators and maintenance professionals seeking a reliable and high-performance flywheel solution.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3906800 Flywheel, designed to meet the demanding requirements of heavy-duty applications.

Cummins Flywheel Part 3906800 Compatibility

The Cummins flywheel part number 3906800 is a critical component that interfaces with various Cummins engine models. This flywheel is designed to work seamlessly with a range of engines, ensuring smooth operation and reliable performance. Here are the specific engines with which this flywheel is compatible:

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B5.9 G

- C GAS PLUS CM556

- C8.3 G

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSC8.3 CM850 (CM2850)

- QSL9 CM850 (CM2850)

Grouping of Compatible Engines

-

QSB Series:

- QSB5.9 30 CM550

- QSB5.9 44 CM550

-

C Series:

- C GAS PLUS CM556

- C8.3 G

-

B Series:

- 4B3.9

- 6B5.9

- B5.9 G

-

QSL Series:

- QSL9 CM850 (CM2850)

-

QSC Series:

- QSC8.3 CM850 (CM2850)

-

6C Series:

- 6C8.3

The flywheel part number 3906800 is engineered to meet the specific needs of these engines, ensuring compatibility across different models and series. This compatibility allows for easier maintenance and repair, as technicians can use a single part number for multiple engine types.

Role of Part 3906800 Flywheel in Engine Systems

The flywheel, designated as part 3906800, is an integral component within the engine system, facilitating smooth operation and efficient energy transfer. Positioned between the engine and the transmission, the flywheel serves multiple functions that contribute to the overall performance of the engine.

Energy Storage and Smooth Operation

One of the primary roles of the flywheel is to store rotational energy. As the engine’s pistons move up and down, they create an inconsistent power delivery. The flywheel mitigates this by storing excess energy during the power stroke and releasing it during the other strokes (intake, compression, and exhaust). This results in a more consistent and smooth operation of the engine 1.

Clutch Engagement

The flywheel is directly involved in the clutch system. When the clutch pedal is depressed, the pressure plate is disengaged from the flywheel, allowing the driver to change gears without stalling the engine. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission and ultimately to the wheels 2.

Vibration Dampening

Engines inherently produce vibrations due to the reciprocating motion of the pistons. The flywheel helps in dampening these vibrations, contributing to a smoother ride and reducing wear and tear on other engine components 3.

Starter Motor Interaction

During engine start-up, the flywheel interacts with the starter motor. The starter motor’s gear engages with the flywheel’s ring gear to crank the engine, initiating the combustion process. A properly functioning flywheel ensures reliable engine starts 4.

Balance and Stability

The flywheel contributes to the overall balance of the engine. Its mass helps in counteracting the forces generated by the moving parts within the engine, promoting stability and reducing the likelihood of mechanical issues.

Conclusion

In summary, the Cummins 3906800 Flywheel plays a multifaceted role in the engine system, enhancing performance, ensuring smooth operation, and contributing to the longevity of the engine components. Its robust design, compatibility with various engine models, and the benefits it offers make it a critical component for heavy-duty truck engines.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ ↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ ↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.