This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

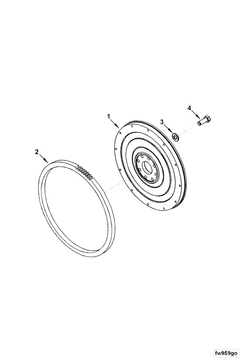

The Cummins 3921250 Flywheel is a component designed to enhance the operation of heavy-duty trucks. Its purpose is to store rotational energy and smooth out engine operation, contributing to overall engine performance and efficiency. Understanding its function and significance is vital for maintaining and optimizing truck performance.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing kinetic energy. This stored energy smooths out the power delivery from the engine, ensuring a more consistent operation. Flywheels play a role in stabilizing engine RPMs, reducing vibrations, and facilitating smoother gear changes in manual transmissions 1.

Purpose of the Cummins 3921250 Flywheel

The Cummins 3921250 Flywheel is specifically engineered to enhance the operation of heavy-duty trucks. It contributes to engine performance by storing rotational energy, which helps to maintain a stable engine speed during power strokes and compression strokes. This stability improves fuel efficiency by allowing the engine to operate more smoothly and reduces wear on other components. Additionally, the flywheel plays a role in the drivetrain functionality by ensuring smooth power transmission from the engine to the transmission 2.

Key Features

The Cummins 3921250 Flywheel is characterized by its robust design and high-quality materials. It is constructed from durable materials that can withstand the high stresses and temperatures encountered in heavy-duty applications. Key features include a balanced design to reduce vibrations, precision machining for optimal performance, and a robust mounting system to ensure secure installation. These features enhance the flywheel’s performance and durability, making it suitable for demanding truck applications.

Benefits

Using the Cummins 3921250 Flywheel offers several benefits. It improves engine efficiency by providing a stable rotational mass that helps to smooth out engine operation. This stability can lead to better fuel economy and reduced emissions. The durable construction of the flywheel enhances its longevity, reducing the need for frequent replacements and maintenance. Additionally, the smooth operation of the flywheel contributes to better overall truck performance, including improved acceleration and towing capacity.

Installation and Compatibility

Proper installation of the Cummins 3921250 Flywheel is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure proper alignment and balance. Compatibility with various truck models and engine configurations should be verified to ensure seamless integration into the drivetrain system. Following the recommended installation procedures will help to avoid potential issues and ensure the flywheel operates as intended.

Troubleshooting and Maintenance

Common issues with the Cummins 3921250 Flywheel may include vibrations, unusual noises, or difficulty in gear shifting. These issues can often be traced to improper installation, wear and tear, or damage to the flywheel. Troubleshooting involves inspecting the flywheel for signs of damage, ensuring proper alignment, and checking for any loose or worn components. Regular maintenance, such as cleaning and inspecting the flywheel for wear, can help to prevent issues and ensure long-term performance.

Performance Enhancements

The Cummins 3921250 Flywheel can contribute to performance enhancements in heavy-duty trucks. By providing a stable rotational mass, it helps to improve acceleration and fuel economy. Additionally, the robust design of the flywheel can support increased towing capacity, making it suitable for demanding applications. Aftermarket modifications, such as upgrading to a lighter or heavier flywheel, can further optimize performance based on specific truck requirements.

Compatibility of Flywheel Part 3921250 with Cummins Engines

The Cummins flywheel part number 3921250 is designed to fit a variety of Cummins engines, ensuring compatibility across different engine configurations. Here is a detailed breakdown of the engines with which this flywheel part is compatible:

Cummins B Series Engines

- 6B5.9

- 6C8.3

- B5.9 G

- B5.9 GAS PLUS CM556

- C8.3 G

These engines are part of the B Series, which are known for their robust performance and reliability in various applications. The flywheel part 3921250 is engineered to match the specific requirements of these engines, ensuring smooth operation and efficient power transfer.

Cummins C Series Engines

- C GAS PLUS CM556

The C Series engines, like the C GAS PLUS CM556, are designed for high-performance applications. The flywheel part 3921250 is compatible with these engines, providing the necessary balance and durability to handle the demands of heavy-duty operations.

Cummins ISB Series Engines

- ISB CM550

- ISB5.9G CM2180

The ISB Series engines are known for their advanced technology and fuel efficiency. The flywheel part 3921250 is designed to fit these engines, ensuring optimal performance and longevity. This compatibility is crucial for maintaining the integrity and efficiency of the engine’s operation.

By ensuring that the flywheel part 3921250 is compatible with these various engines, Cummins maintains a high standard of quality and reliability across its engine lineup. This compatibility allows for easier maintenance and repair, as technicians can use a single part number for multiple engine models, simplifying inventory management and reducing downtime.

Role of Part 3921250 Flywheel in Engine Systems

The flywheel, identified by part number 3921250, is a pivotal component in the operation of engine systems. It is engineered to store rotational energy and smooth out the power delivery from the engine’s combustion cycles.

When the engine’s pistons move due to combustion, the flywheel absorbs the energy and uses its mass to maintain a consistent rotational speed. This is particularly important in internal combustion engines where the power delivery is not continuous but rather in pulses corresponding to each cylinder’s firing sequence.

The flywheel is connected to the crankshaft via the flexplate or direct mounting, depending on the engine design. This connection ensures that the rotational energy is efficiently transferred from the engine to the transmission system.

In manual transmission vehicles, the flywheel plays an additional role in the clutch system. It interfaces with the pressure plate and clutch disc, allowing for smooth engagement and disengagement of the engine from the transmission. This is essential for gear changes without jarring the drivetrain.

Furthermore, the flywheel’s design contributes to the engine’s balance. Its mass helps counteract the reciprocating motion of the pistons, reducing vibrations and enhancing the engine’s overall stability and longevity.

In summary, the flywheel (part 3921250) is integral to the efficient operation of engine systems, providing energy storage, smooth power delivery, and contributing to the mechanical balance of the engine.

Conclusion

The Cummins 3921250 Flywheel is a critical component for heavy-duty trucks, designed to store rotational energy and smooth out engine operation. Its robust design, high-quality materials, and precise engineering contribute to enhanced engine performance, fuel efficiency, and durability. Proper installation, regular maintenance, and understanding its role in the engine system are essential for maximizing the benefits of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.