This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

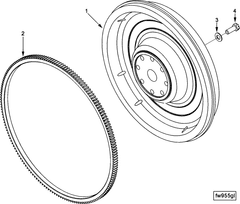

The Cummins 3936424 Flywheel is a critical component in heavy-duty trucks, designed to enhance engine performance and efficiency. Its role in the engine system is to ensure smooth operation and reliable power delivery.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and smooths out the power delivery of an engine. It operates on the principle of inertia, maintaining a consistent rotational speed despite the intermittent power pulses from the engine’s combustion cycles 1. A well-designed flywheel contributes to engine stability, efficiency, and overall smoothness.

Purpose of the Cummins 3936424 Flywheel

This Cummins part is engineered to support the operation of heavy-duty trucks. It stores kinetic energy during the power stroke and releases it during the other strokes, maintaining a consistent rotational speed. This contributes to engine efficiency and performance by ensuring smooth power delivery and reducing strain on the engine components 2.

Key Features

The 3936424 Flywheel is characterized by its robust design and construction. It is made from high-quality materials that offer durability and resistance to wear. The flywheel is precision-balanced to minimize vibrations and ensure smooth operation. Its weight is optimized to provide the necessary inertia without adding excessive load to the engine. Unique characteristics such as its surface finish and damping features enhance its functionality and longevity.

Benefits

This part offers several advantages, including improved engine smoothness, enhanced fuel efficiency, and increased durability. These benefits directly impact the overall performance of the truck by ensuring consistent power delivery, reducing fuel consumption, and prolonging the lifespan of the engine components 3.

Installation Process

Proper installation of the 3936424 Flywheel is essential for optimal performance and longevity. The process involves preparing the engine, aligning the flywheel with the crankshaft, securing it in place, and ensuring all connections are tight and properly torqued. Following best practices during installation helps prevent issues such as misalignment, which can lead to vibrations and reduced efficiency.

Common Issues and Troubleshooting

Flywheels can encounter several problems, such as wear, noise, and vibration. Wear can occur due to friction and heat, while noise and vibration may indicate misalignment or imbalance. Troubleshooting these issues involves inspecting the flywheel for signs of damage, ensuring proper alignment, and balancing the flywheel if necessary. Addressing these problems promptly helps maintain the performance and reliability of the engine.

Maintenance Tips

Regular maintenance is key to prolonging the lifespan of the 3936424 Flywheel. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could affect performance, and ensuring all connections are secure. Knowing when to consider replacement is also important, as a worn flywheel can lead to decreased engine efficiency and increased risk of failure.

Compatibility and Applications

The 3936424 Flywheel is designed for use in specific types of engines and truck models. Its applicability extends to various commercial and industrial settings, where reliable and efficient engine performance is crucial. Understanding the compatibility of this flywheel with different engine types ensures optimal performance and integration within the truck’s engine system.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, with a history of innovation and quality in engine components. The company’s commitment to excellence is evident in its product line, including the 3936424 Flywheel. Cummins’ reputation for reliability and performance underscores its position as a leader in the industry, providing components that meet the demanding requirements of heavy-duty applications.

Role of Part 3936424 Flywheel in Engine Systems

The 3936424 Flywheel is integral to the operation of an engine system, serving as a pivotal component in the management of rotational energy. It is connected to the crankshaft and plays a significant role in the smooth operation of the engine by storing rotational energy and delivering it as needed.

When the engine’s pistons move, they generate power strokes that cause the crankshaft to rotate. The flywheel, due to its mass and inertia, helps in maintaining a consistent rotational speed of the crankshaft. This is particularly important during the phases when the engine is not producing power, such as between the power strokes of the pistons.

The flywheel also interfaces with the clutch system in manual transmissions. When the clutch is engaged, the flywheel transmits engine power to the transmission, allowing the vehicle to move. Conversely, when the clutch is disengaged, the flywheel continues to rotate independently of the transmission, enabling smooth gear changes.

Furthermore, the flywheel houses the starter ring gear, which engages with the starter motor’s pinion gear to crank the engine during startup. This interaction is essential for initiating engine operation.

Conclusion

In summary, the 3936424 Flywheel is a fundamental component that ensures the engine operates smoothly, efficiently transmits power, and facilitates essential functions like starting the engine and changing gears in manual transmissions. Proper installation, maintenance, and understanding of its role in the engine system are crucial for optimal performance and longevity.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Tim Gilles, Automotive Service: Inspection, Maintenance, Repair: 2nd Edition, Cengage Learning, 2020.

↩ -

Wolf-Henning Schneider, Pistons and Engine Testing, Springer Nature, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.