This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

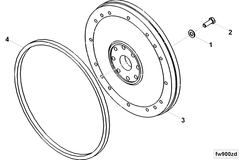

The Cummins 3936821 Flywheel is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its purpose is to store rotational energy and contribute to the smooth functioning of the engine. Understanding its function and significance is key to appreciating its role in the overall performance of commercial trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device specifically designed to store rotational energy. It consists of a heavy disk attached to a rotating shaft, which is geared to the engine. The fundamental principle behind a flywheel is the conservation of angular momentum. When the engine produces power, the flywheel stores a portion of that energy. During the phases when the engine is not producing power, the flywheel releases this stored energy, helping to maintain a consistent rotational speed. This mechanism smooths out the engine’s operation, reducing fluctuations in speed and providing a more stable power delivery 1.

Purpose of the Cummins 3936821 Flywheel

This part is engineered to play a specific role in the operation of a truck’s engine. It stores rotational energy during the power stroke of the engine’s cycle and releases it during the other strokes, thereby contributing to engine performance. This energy storage and transfer mechanism is vital during the combustion process, ensuring that the engine operates smoothly and efficiently. The flywheel’s role in balancing the engine’s rotational forces also helps in reducing wear and tear on the engine components 2.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. Its design incorporates a robust construction that can withstand the high stresses and loads encountered in commercial truck applications. The materials used in its construction are selected for their strength and resistance to wear, ensuring long-lasting performance. Additionally, the flywheel may feature specific design elements that improve its efficiency in storing and transferring energy, contributing to overall engine performance.

Benefits

Utilizing this part offers several benefits. It contributes to improved engine efficiency by ensuring a smooth transfer of energy throughout the engine cycle. The durable construction of the flywheel enhances its reliability under heavy-duty conditions, reducing the likelihood of failure. Furthermore, the flywheel’s design helps in maintaining consistent engine performance, which is crucial for the operation of commercial trucks.

Installation and Compatibility

Proper installation of this part is crucial for ensuring its optimal performance and longevity. Installation guidelines should be followed to ensure that the flywheel is correctly aligned and secured. Compatibility with various truck models and engine types is an important consideration, ensuring that the flywheel functions effectively within the specific engine system it is designed for 3.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and optimal performance of this part. This may include periodic inspections for signs of wear or damage, ensuring that all connections are secure, and addressing any issues promptly. Common issues that may arise include uneven wear or damage to the flywheel, which can affect engine performance. Troubleshooting tips may involve checking for proper alignment, ensuring that the flywheel is free from obstructions, and addressing any unusual noises or vibrations that may indicate a problem.

Performance Enhancements

This part can contribute to overall truck performance in several ways. By ensuring a smooth transfer of energy throughout the engine cycle, it can improve acceleration and fuel efficiency. The flywheel’s role in balancing the engine’s rotational forces also contributes to a smoother engine operation, enhancing the driving experience.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance automotive components. The company’s focus on research and development ensures that its products, including the Cummins 3936821 Flywheel, meet the demanding requirements of commercial truck applications.

Compatibility of Flywheel Part 3936821 with Cummins Engines

The Cummins flywheel part 3936821 is designed to fit a variety of Cummins engines, each of which is identified by specific model names and configurations. Here is a breakdown of the compatibility of this flywheel part with the listed engines:

4B3.9 and B3.9 G

This flywheel part is compatible with the 4B3.9 and B3.9 G engines. These engines are part of the Cummins B-series, known for their reliability and efficiency in various applications.

6B5.9 and B5.9 G

This part is also suitable for the 6B5.9 and B5.9 G engines. These engines are part of the Cummins B-series and are often used in medium-duty applications.

B5.9 GAS PLUS CM556

The part 3936821 fits the B5.9 GAS PLUS CM556 engine. This engine is a variant of the B5.9 series, designed for gas applications with enhanced performance features.

G5.9

The G5.9 engine is another model where this part can be used. This engine is part of the Cummins G-series, which is known for its robust design and durability.

QSB3.9 30 CM550

The QSB3.9 30 CM550 engine is compatible with this part. This engine is part of the Cummins QSB series, which is widely used in agricultural and industrial applications.

QSB4.5 CM850 (CM2850)

This part fits the QSB4.5 CM850 (CM2850) engine. This engine is part of the Cummins QSB series, known for its versatility and performance.

QSB5.9 30 CM550 and QSB5.9 44 CM550

Both the QSB5.9 30 CM550 and QSB5.9 44 CM550 engines are compatible with this part. These engines are part of the Cummins QSB series, offering a range of power options for various applications.

QSB6.7 CM850 (CM2850)

The QSB6.7 CM850 (CM2850) engine is another model that can use this part. This engine is part of the Cummins QSB series, designed for high-performance applications.

QSB7 CM2880 B117

Finally, the QSB7 CM2880 B117 engine is compatible with this part. This engine is part of the Cummins QSB series, known for its high power output and efficiency.

Understanding the Role of Part 3936821 Flywheel in Engine Systems

The flywheel, specifically part 3936821, is an integral component in the operation of engine systems, facilitating smooth and efficient power transmission. Its primary function is to store rotational energy and deliver it consistently to the crankshaft, ensuring a stable engine operation even during the intervals between power strokes.

Interaction with the Crankshaft

The flywheel is bolted to the rear of the crankshaft. As the engine operates, the flywheel rotates along with the crankshaft, storing kinetic energy during the power stroke. This stored energy is then utilized during the other phases of the engine cycle—intake, compression, and exhaust—to maintain a uniform rotational speed.

Relationship with the Clutch System

In manual transmission vehicles, the flywheel works in conjunction with the clutch system. When the clutch pedal is depressed, the pressure plate is disengaged from the flywheel, allowing the driver to shift gears without interrupting the engine’s rotation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission.

Contribution to Vibration Dampening

One of the lesser-known functions of the flywheel is its role in dampening vibrations. The mass of the flywheel helps to smooth out the pulses of torque generated by the engine’s combustion cycles. This results in a more stable and less jerky operation, which is particularly beneficial in high-performance engines where combustion events are more frequent and intense.

Support for Starter Motor Engagement

During engine start-up, the flywheel provides a surface for the starter motor’s pinion gear to engage. The teeth on the flywheel’s outer rim mesh with the pinion gear, allowing the starter motor to turn the crankshaft and initiate the engine’s operation.

Influence on Engine Balancing

The flywheel’s mass and design also contribute to the overall balancing of the engine. By counteracting the reciprocating masses of the pistons and connecting rods, the flywheel helps to minimize vibrations and ensure smoother engine operation.

Conclusion

In summary, the 3936821 flywheel plays a multifaceted role in engine systems, from energy storage and transmission to vibration dampening and engine balancing. Its seamless integration with components like the crankshaft, clutch system, and starter motor underscores its significance in maintaining efficient and reliable engine performance.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.