This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

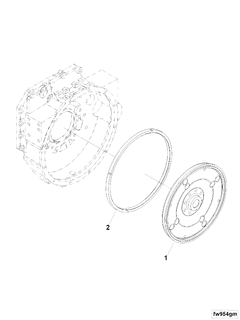

The Cummins 3974235 Flywheel is a component designed for use in commercial trucks, specifically engineered to enhance the performance and efficiency of the engine. Its role is significant in maintaining the smooth operation of the vehicle by storing rotational energy and ensuring consistent power delivery 2.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and smooths out the power delivery of an internal combustion engine. It operates on the principle of inertia, resisting changes in rotational speed and providing a stable source of energy. Within an engine system, the flywheel connects to the crankshaft and interacts with the clutch to facilitate gear changes and maintain engine momentum 1.

Purpose of the Cummins 3974235 Flywheel

The Cummins 3974235 Flywheel plays a role in the operation of a truck by storing rotational energy during the power stroke of the engine and releasing it during the other strokes. This action helps to maintain a consistent rotational speed, which is crucial for smooth engine operation. It also assists in the engagement and disengagement of the clutch, ensuring seamless gear transitions. Additionally, the flywheel contributes to reducing vibrations and enhancing the overall stability of the engine 2.

Key Features

The Cummins 3974235 Flywheel is characterized by its robust design and high-quality materials. It is constructed from durable alloys that provide strength and longevity. The flywheel features a balanced weight distribution to minimize vibrations and ensure smooth operation. Additionally, it includes precision-machined surfaces for optimal engagement with the clutch and crankshaft 2.

Benefits

The Cummins 3974235 Flywheel offers several advantages. It contributes to improved engine efficiency by maintaining consistent rotational speed and reducing energy loss during gear changes. The smooth operation of the flywheel leads to a more comfortable driving experience and reduced wear on other engine components. Additionally, the efficient energy storage and release can potentially lead to increases in fuel economy 2.

Installation Process

Proper installation of the Cummins 3974235 Flywheel involves several steps. First, ensure the engine is disconnected from the power source for safety. Remove the old flywheel by disconnecting it from the crankshaft and clutch. Inspect the mating surfaces for any damage or irregularities. Install the new flywheel, ensuring it is properly aligned with the crankshaft and clutch. Use the appropriate tools to secure the flywheel in place. Finally, reassemble the engine components and perform a test run to ensure everything is functioning correctly 2.

Common Issues and Troubleshooting

Frequent problems associated with the Cummins 3974235 Flywheel include excessive vibrations, difficulty in gear engagement, and unusual noises. These issues can often be traced to improper installation, wear and tear, or damage to the flywheel or related components. Troubleshooting methods include inspecting the flywheel for cracks or warping, checking the alignment and fit with the crankshaft and clutch, and ensuring all bolts and fasteners are tightened to the manufacturer’s specifications 2.

Maintenance Tips

Regular maintenance practices are vital for ensuring the longevity and optimal performance of the Cummins 3974235 Flywheel. Inspect the flywheel during routine engine maintenance for signs of wear or damage. Ensure that the clutch and crankshaft are in good condition, as these components interact directly with the flywheel. Keep the flywheel clean and free from debris to prevent unnecessary wear. Following the manufacturer’s recommended service intervals will help maintain the flywheel’s performance and extend its lifespan 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has built a reputation for innovation, quality, and reliability in the commercial truck industry. The company is known for its commitment to customer satisfaction and continuous improvement, making it a trusted name among fleet operators and engine manufacturers 2.

Cummins Flywheel 3974235 Compatibility

The Cummins Flywheel part number 3974235 is designed to fit a variety of Cummins engines, ensuring smooth operation and efficient power transfer. Here is a breakdown of the engines with which this flywheel is compatible:

ISB Series

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISBE Series

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

ISC Series

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

ISL Series

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

Gas Plus Series

- C GAS PLUS CM556

- L GAS PLUS CM556

This flywheel is engineered to provide the necessary balance and weight to ensure optimal engine performance across these various models. It is crucial for maintaining the integrity of the engine’s rotational dynamics and ensuring that the engine runs smoothly and efficiently 2.

Role of Part 3974235 Flywheel in Engine Systems

The flywheel, specifically part 3974235, is integral to the operation of various engine systems. It serves as a vital link between the engine and transmission, ensuring smooth power delivery and efficient energy management 2.

Interaction with the Clutch System

When the engine is running, the flywheel is directly connected to the crankshaft, allowing it to spin at the same rate. During gear changes, the clutch system disengages the flywheel from the engine, enabling seamless shifting without interrupting the engine’s operation. Once the gear change is complete, the clutch re-engages, reconnecting the flywheel to the crankshaft and transmitting power to the transmission 2.

Contribution to the Starter System

The flywheel also plays a significant role in the starter system. The starter motor engages with the flywheel’s ring gear to crank the engine. The flywheel’s mass and inertia help the engine overcome compression and start smoothly. This interaction ensures reliable engine starts, especially in cold conditions where engine oil viscosity is higher 2.

Influence on the Vibration Dampening System

Flywheels are often designed with vibration dampening features to reduce the inherent vibrations produced by the engine. Part 3974235, with its specific design, helps in absorbing and dissipating these vibrations, leading to a smoother engine operation and reduced wear on connected components 2.

Relationship with the Exhaust System

Although indirectly, the flywheel affects the exhaust system by maintaining consistent engine speed and power delivery. Stable engine operation ensures that the exhaust system functions efficiently, minimizing backpressure and enhancing overall engine performance 2.

Impact on the Fuel Injection System

Consistent engine speed and smooth power delivery facilitated by the flywheel contribute to the efficient operation of the fuel injection system. Stable engine RPMs allow for precise fuel delivery, optimizing combustion efficiency and reducing emissions 2.

Connection to the Ignition System

The flywheel’s consistent rotation ensures that the ignition system operates within the designed parameters. This stability is essential for timely spark delivery, which is critical for efficient combustion and overall engine performance 2.

Effect on the Cooling System

Stable engine operation, aided by the flywheel, ensures that the cooling system functions effectively. Consistent engine speed helps maintain optimal coolant flow, preventing overheating and ensuring the engine operates within safe temperature ranges 2.

Role in the Electrical System

The flywheel’s smooth operation contributes to the stability of the electrical system. Consistent engine speed ensures that the alternator produces a steady electrical output, powering the vehicle’s electrical components reliably 2.

Conclusion

In summary, part 3974235 flywheel is a multifaceted component that interacts with various engine systems to ensure smooth, efficient, and reliable engine operation. Its role in storing rotational energy, facilitating gear changes, and maintaining engine stability is crucial for the overall performance of commercial trucks 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.