This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

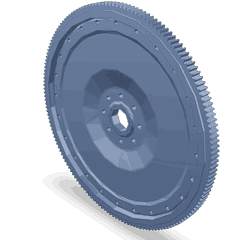

The Cummins 3974452 Flywheel is a critical component in commercial trucks, essential for the efficient operation of these vehicles. Its primary function is to store rotational energy, contributing to the smooth operation of the engine. Understanding the flywheel’s role and significance is important for maintaining the efficiency and performance of commercial trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that utilizes rotational inertia to store energy. It consists of a heavy disc attached to the engine’s crankshaft. As the engine operates, the flywheel accumulates kinetic energy, which it releases to maintain the engine’s momentum between power strokes. This mechanism stabilizes the engine’s rotational speed and ensures consistent power delivery 1.

Purpose of the Cummins 3974452 Flywheel

The Cummins 3974452 Flywheel is integral to the operation of a truck’s engine. It stores rotational energy generated during the power stroke and releases it during the other strokes (intake, compression, and exhaust), thereby smoothing out the engine’s operation. This results in a more stable and efficient engine performance, reducing the strain on other components and enhancing overall drivability 2.

Key Features

The Cummins 3974452 Flywheel is characterized by its robust design and high-quality materials. It is engineered to withstand the demanding conditions of commercial truck operations. The flywheel’s design includes precision balancing to minimize vibrations and ensure smooth operation. Additionally, it is constructed from durable materials that offer resistance to wear and fatigue, contributing to its longevity and reliability.

Benefits

The Cummins 3974452 Flywheel offers several benefits. It enhances engine efficiency by maintaining consistent rotational speed, which leads to improved fuel economy. The flywheel also reduces wear on other engine components by smoothing out the power delivery, thereby extending the engine’s lifespan. Furthermore, it contributes to enhanced drivability by providing a stable and consistent engine operation, which is particularly important in heavy-duty applications.

Installation Process

Installing the Cummins 3974452 Flywheel requires careful attention to detail. The process involves removing the old flywheel, cleaning the mating surfaces, and ensuring the engine is properly aligned. The new flywheel should be installed with the correct torque specifications to ensure a secure fit. It is also important to use the appropriate tools and follow manufacturer guidelines to avoid damage during installation.

Common Issues and Troubleshooting

Common issues with the Cummins 3974452 Flywheel may include vibrations, unusual noises, or difficulty in starting the engine. These problems can often be traced to improper installation, wear and tear, or misalignment. Troubleshooting involves inspecting the flywheel for signs of damage, ensuring proper alignment, and checking for any loose connections. Regular maintenance and timely replacements can prevent many of these issues.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3974452 Flywheel, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring proper alignment, and cleaning the mating surfaces. Additionally, following the manufacturer’s guidelines for torque specifications during installation or reinstallation can help maintain the flywheel’s integrity and performance.

Compatibility and Applications

The Cummins 3974452 Flywheel is designed to be compatible with a range of truck models and engine types. Its applications span various operating conditions, making it a versatile component for commercial truck fleets. Ensuring compatibility with the specific truck model and engine type is crucial for optimal performance and reliability.

Manufacturer: Cummins

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry. With a rich history of innovation and quality, Cummins is committed to producing reliable and high-performance components. The company’s reputation is built on its dedication to engineering excellence and customer satisfaction, making it a trusted name in the industry.

Compatibility of Cummins Flywheel Part 3974452

The Cummins flywheel part number 3974452 is designed to fit a variety of Cummins engine models. This flywheel is integral to the engine’s operation, helping to maintain smooth engine rotation and providing a mounting point for the starter motor. Here is a detailed breakdown of the engines it is compatible with:

ISC Series Engines

- ISC CM554

- ISL CM554

- QSC8.3 CM554

The flywheel part 3974452 is suitable for the ISC and ISL series engines, which are part of the Cummins QSC8.3 CM554 family. These engines are known for their robust performance and reliability in various applications.

QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

The flywheel part 3974452 also fits the QSC8.3 CM850 (CM2850) and QSC9 CM2250 / QSL9 CM2250 engines. These engines are part of the larger QSC series, offering high power output and efficiency.

QSL Series Engines

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM554

- QSL9 CM850 (CM2850)

The QSL series engines, including the QSL8.9 CM2150 L141, QSL9 CM2250, QSL9 CM2350 L102, QSL9 CM554, and QSL9 CM850 (CM2850), are also compatible with the flywheel part 3974452. These engines are designed for heavy-duty applications, providing excellent performance and durability.

By ensuring the correct flywheel is used, engine performance and longevity can be maintained, providing reliable operation across these various engine models.

Role of Part 3974452 Flywheel in Engine Systems

The flywheel, specifically part 3974452, is integral to the operation of an engine system. It serves as a vital link between the engine and the transmission, ensuring smooth power delivery.

When the engine’s pistons move, they generate rotational force. This force is transferred to the flywheel via the crankshaft. The flywheel, due to its mass and inertia, stores this rotational energy. As the engine’s speed fluctuates during operation, the flywheel helps to stabilize these variations, providing a consistent rotational speed to the transmission.

Additionally, the flywheel plays a significant role in the clutch system. When the clutch is engaged, the flywheel is directly connected to the pressure plate, which in turn presses against the clutch disc. This connection allows power to be transmitted from the engine to the transmission. When the clutch is disengaged, the flywheel continues to rotate independently, allowing the driver to shift gears without interrupting the engine’s operation.

Furthermore, in engines equipped with a starter motor, the flywheel houses the ring gear. This gear engages with the starter motor’s pinion gear during engine start-up, facilitating the initial cranking of the engine.

In summary, part 3974452 flywheel is essential for maintaining engine stability, facilitating smooth gear changes, and aiding in engine start-up. Its interaction with components like the crankshaft, clutch system, and starter motor underscores its significance in the engine system.

Conclusion

The Cummins 3974452 Flywheel is a vital component in the operation of commercial truck engines. Its role in storing rotational energy, stabilizing engine speed, and facilitating smooth power delivery cannot be overstated. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this part. By understanding its functions and benefits, fleet managers and mechanics can better maintain and optimize the performance of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.