This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

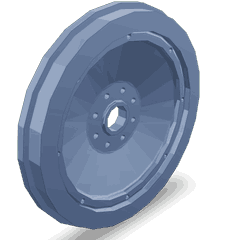

The Cummins 3974460 Flywheel is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its primary function is to store rotational energy and smooth out the power delivery from the engine to the transmission. This part is integral to maintaining consistent engine operation and ensuring efficient power transfer 1.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy. It consists of a heavy disc attached to a rotating shaft. When the engine produces power, the flywheel stores this energy and releases it during the phases when the engine requires additional power, such as during gear changes or when the engine is idling. This mechanism helps in stabilizing the engine’s rotational speed and provides a smoother operation 2.

Role of the 3974460 Flywheel in Truck Operation

This Cummins part is specifically engineered to interact with other engine components to enhance the overall performance of a truck. It works in conjunction with the clutch to transfer power from the engine to the transmission. During engine operation, the flywheel absorbs excess energy and releases it as needed, ensuring a consistent power supply to the transmission. This interaction is vital for smooth gear shifts and maintaining engine stability under varying load conditions 3.

Key Features of the 3974460 Flywheel

The 3974460 Flywheel is characterized by several key features that enhance its performance. It is designed with a robust construction to withstand the high stresses and torques encountered in commercial truck applications. The flywheel is made from high-strength materials, ensuring durability and longevity. Additionally, its design includes precision balancing to minimize vibrations and ensure smooth operation 4.

Benefits of Using the 3974460 Flywheel

Utilizing this part offers several advantages. It contributes to improved engine performance by providing consistent power delivery and reducing engine vibrations. The durable construction ensures long-term reliability, while the efficient design enhances overall engine efficiency. These benefits result in a more stable and powerful truck operation 5.

Installation Considerations

Proper installation of the 3974460 Flywheel is crucial for optimal performance. It is important to ensure that the flywheel is correctly aligned with the engine and transmission components. This may require the use of specialized tools and following manufacturer guidelines to achieve precise installation. Attention to detail during installation helps prevent issues such as misalignment or improper torque, which can affect performance 6.

Maintenance and Troubleshooting

Regular maintenance of the 3974460 Flywheel is necessary to ensure continued optimal performance. This includes checking for signs of wear or damage, ensuring proper alignment, and verifying that all connections are secure. Common issues may include vibrations, which can indicate imbalance or misalignment, and unusual noises, which may signal wear or damage. Addressing these issues promptly helps maintain the flywheel’s efficiency and longevity 7.

Performance Enhancements

The 3974460 Flywheel contributes to overall engine performance by providing a smooth and consistent power delivery. Its design helps in reducing engine vibrations, leading to a smoother operation. Additionally, the flywheel’s ability to store and release rotational energy enhances the truck’s power delivery, resulting in better acceleration and stability under varying load conditions 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality and reliable engine components. The company’s commitment to innovation and excellence ensures that its products, like the 3974460 Flywheel, meet the demanding requirements of commercial truck applications 9.

Compatibility

The Cummins flywheel part number 3974460 is designed to be compatible with a range of Cummins engines, ensuring a reliable and efficient power transmission system. This flywheel is engineered to work seamlessly with the following engine models:

- 6C8.3

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSL9 CM554

These engines are part of Cummins’ diverse lineup, each tailored for specific applications and performance requirements. The flywheel part 3974460 is meticulously crafted to meet the demands of these engines, providing a critical component in the engine’s operation. Its design ensures smooth power delivery and optimal engine performance across the specified engine models 10.

Role of the 3974460 Flywheel in Engine Systems

The flywheel, specifically part 3974460, is integral to the operation of an engine system. It serves as a pivotal component that interfaces with several other engine parts to ensure smooth and efficient performance.

Interaction with the Crankshaft

The flywheel is directly connected to the crankshaft via a series of bolts. This connection allows the flywheel to store rotational energy generated by the engine. As the crankshaft rotates, the flywheel absorbs and stores this energy, which is then used to maintain the engine’s momentum between power strokes 11.

Engagement with the Clutch

In manual transmission systems, the flywheel works in conjunction with the clutch. When the clutch pedal is depressed, the pressure plate disengages from the flywheel, allowing the driver to shift gears without interrupting the engine’s rotation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission 12.

Balance and Vibration Dampening

The flywheel’s mass helps to balance the engine by counteracting the reciprocating motion of the pistons. This balancing act reduces vibrations and ensures a smoother operation. Additionally, the flywheel acts as a vibration dampener, absorbing shocks and irregularities in the engine’s rotation, which contributes to a more stable and consistent power delivery 13.

Starter Motor Interaction

During engine start-up, the flywheel engages with the starter motor’s pinion gear. The starter motor rotates the flywheel, which in turn rotates the crankshaft, initiating the engine’s combustion cycle. This interaction is essential for the engine to transition from a stationary state to an operational one 14.

Flywheel Housing and Engine Mounts

The flywheel is housed within the flywheel housing, which is securely attached to the engine block via engine mounts. This housing not only protects the flywheel but also provides a stable platform for it to operate. The engine mounts absorb and isolate vibrations, further enhancing the engine’s stability and performance 15.

Integration with the Transmission

In automatic transmission systems, the flywheel’s role is somewhat modified. Instead of interacting with a clutch, the flywheel connects to the torque converter. The torque converter uses fluid coupling to transmit engine power to the transmission, allowing for seamless gear changes without the need for a traditional clutch mechanism 16.

Conclusion

In summary, the 3974460 flywheel is a multifaceted component that interacts with the crankshaft, clutch, starter motor, flywheel housing, engine mounts, and transmission to ensure the engine operates efficiently and smoothly. Its robust design, precision balancing, and compatibility with various Cummins engines make it a critical component in the engine’s operation, contributing to improved performance, reduced vibrations, and enhanced stability under varying load conditions.

-

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Bosch, Robert. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Cummins Inc. X15 CM2450 X134B - Performance Series, Service Manual (5613373).

↩ -

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Bosch, Robert. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Cummins Inc. X15 CM2450 X134B - Performance Series, Service Manual (5613373).

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Cummins Inc. X15 CM2450 X134B - Performance Series, Service Manual (5613373).

↩ -

Cummins Inc. X15 CM2450 X134B - Performance Series, Service Manual (5613373).

↩ -

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Bosch, Robert. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Cummins Inc. X15 CM2450 X134B - Performance Series, Service Manual (5613373).

↩ -

Bosch, Robert. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Cummins Inc. X15 CM2450 X134B - Performance Series, Service Manual (5613373).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.