This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

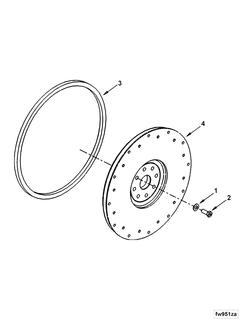

The Cummins 3977540 Flywheel is a critical component in commercial trucks, essential for the efficient operation of these vehicles. Its primary function is to store rotational energy, contributing to the smooth functioning of the engine. Understanding its role and significance is vital for appreciating its impact on the overall performance of commercial trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device designed to store rotational energy efficiently. It consists of a heavy disc mounted on the same shaft as the engine. The principle of conservation of angular momentum underpins its operation. When the engine generates power, the flywheel stores this energy and releases it during phases when the engine is not producing power, such as between combustion cycles. This mechanism smooths out the engine’s operation, reduces vibrations, and ensures consistent power delivery 1.

Purpose of the 3977540 Flywheel

This Cummins part is engineered to enhance the operation of a truck’s engine. It stores rotational energy generated during the combustion process and transfers this energy to the transmission system. This aids in maintaining engine momentum, ensuring a steady power output, and contributing to the overall efficiency and performance of the truck 2.

Key Features

The 3977540 Flywheel is characterized by its robust design and the use of high-quality materials. These features contribute to its performance and durability. The flywheel is crafted to withstand the demanding conditions of commercial truck operations, ensuring reliable performance over time. Its design also facilitates efficient energy transfer and storage, enhancing engine operation 3.

Benefits

Utilizing the 3977540 Flywheel in commercial trucks offers several advantages. It contributes to improved engine efficiency by ensuring smooth energy transfer and storage. The flywheel’s durable construction enhances the longevity of the engine components, providing reliable performance under heavy-duty conditions. Additionally, its efficient design helps in reducing engine vibrations, leading to a smoother operation.

Installation Considerations

Proper installation of the 3977540 Flywheel is crucial for ensuring its optimal performance. This process involves adhering to specific torque specifications and alignment procedures. Preparatory steps may include cleaning the mating surfaces and inspecting the flywheel for any damage. Following these guidelines ensures that the flywheel is securely and correctly installed, contributing to the efficient operation of the engine.

Maintenance and Troubleshooting

Regular maintenance of the 3977540 Flywheel is essential for ensuring its continued optimal performance. This includes conducting regular inspections for signs of wear or damage. Common issues may involve uneven wear on the flywheel surface or damage to the teeth. Addressing these issues promptly can prevent more significant problems and ensure the flywheel continues to function effectively.

Compatibility and Applications

The 3977540 Flywheel is designed for specific types of engines and truck models. Its suitability for various commercial applications and operating conditions makes it a versatile component in the automotive industry. Understanding its compatibility ensures that it is used in the appropriate applications, maximizing its benefits.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its high-quality components. With a rich history and a strong reputation, Cummins is committed to producing reliable and efficient automotive parts. The company’s dedication to quality and innovation is evident in its wide range of products, including the 3977540 Flywheel.

Cummins Flywheel Part 3977540 Compatibility

The Cummins flywheel part number 3977540 is designed to fit a variety of Cummins engines, ensuring smooth operation and efficient power transfer. Here is a breakdown of its compatibility with the listed engines:

B6.7 Series Engines

- B6.7 CM2670 B153B

- B6.7 G CMOH6.0 B125

The flywheel part 3977540 is compatible with the B6.7 series engines, which are known for their robust performance and reliability. These engines are often used in heavy-duty applications, and the flywheel ensures that the engine’s rotational energy is efficiently managed.

ISB/ISD Series Engines

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

The ISB/ISD series engines, including the 4.5 and 6.7 liter variants, also support the use of the flywheel part 3977540. These engines are widely used in both on-highway and off-highway applications, and the flywheel plays a crucial role in maintaining engine balance and performance.

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series engines, which include the CM2150, CM800, and CM850 variants, are designed for a range of applications from industrial to marine. The flywheel part 3977540 is engineered to fit these engines, ensuring that they operate smoothly and efficiently across different environments.

Role of Part 3977540 Flywheel in Engine Systems

The flywheel, identified by part number 3977540, is integral to the operation of various engine systems. It serves as a vital link between the engine and the transmission, ensuring smooth power delivery and efficient operation.

Interaction with the Crankshaft

The flywheel is bolted to the rear of the crankshaft. This connection allows the flywheel to rotate in sync with the crankshaft, storing rotational energy during the power stroke and releasing it during the other strokes. This interaction helps maintain engine momentum, particularly during the intake, compression, and exhaust strokes when the engine is not producing power.

Engagement with the Starter Motor

During engine start-up, the flywheel engages with the starter motor. The starter motor’s pinion gear meshes with the flywheel’s ring gear, allowing the starter to turn the engine over. This engagement is essential for initiating the combustion process and bringing the engine to operational speed.

Connection to the Clutch

In manual transmission systems, the flywheel works in conjunction with the clutch. The pressure plate, connected to the flywheel, applies constant pressure to the friction disc. When the clutch pedal is pressed, the pressure plate moves away from the flywheel, disengaging the clutch and allowing the driver to shift gears smoothly. Upon releasing the clutch pedal, the pressure plate presses the friction disc against the flywheel, re-engaging the clutch and transmitting power from the engine to the transmission.

Balance and Vibration Reduction

The flywheel’s mass contributes to engine balance by counteracting the reciprocating motion of the pistons. This balance reduces vibrations and smooths out the engine’s operation, leading to a more stable and reliable performance.

Energy Storage and Release

One of the flywheel’s primary functions is to store rotational energy. As the engine’s crankshaft rotates, the flywheel accumulates kinetic energy. This stored energy is then released to help the engine complete non-power strokes, ensuring consistent rotational speed and enhancing overall engine efficiency.

Integration with the Torque Converter (Automatic Transmissions)

In automatic transmission systems, the flywheel’s role is somewhat different. Here, the flywheel is often replaced by a flexplate, which serves a similar purpose. The flexplate connects to the torque converter, which uses fluid coupling to transmit engine power to the transmission. The flexplate’s design allows for the necessary flexibility to accommodate the torque converter’s operation.

Summary of Flywheel Functions

- Crankshaft Connection: Synchronizes rotation and maintains engine momentum.

- Starter Motor Engagement: Facilitates engine start-up by meshing with the starter motor’s pinion gear.

- Clutch Operation: Works with the clutch system to enable smooth gear changes in manual transmissions.

- Engine Balance: Reduces vibrations and enhances engine stability.

- Energy Management: Stores and releases rotational energy to maintain consistent engine speed.

- Torque Converter Integration: In automatic transmissions, the flexplate (a variant of the flywheel) connects to the torque converter for fluid power transmission.

Conclusion

The Cummins 3977540 Flywheel is a vital component in the operation of commercial trucks. Its role in storing rotational energy, ensuring smooth engine operation, and enhancing overall efficiency cannot be overstated. Proper installation, regular maintenance, and understanding its compatibility with various engine types are essential for maximizing its benefits. Cummins’ commitment to quality and innovation is reflected in the design and performance of this part, making it a reliable choice for heavy-duty applications.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Konrad Reif, Automotive Mechatronics, Springer Vieweg, 2015.

↩ -

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.