This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

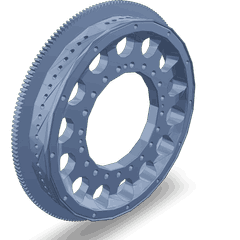

The Cummins 4012485 Flywheel is a component designed for use in commercial trucks, enhancing the performance and reliability of engines. This flywheel is engineered to ensure smooth and efficient engine operation under various conditions.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing energy during acceleration and releasing it during deceleration. This mechanism smooths out the power delivery from the engine to the transmission, contributing to a more stable and efficient operation 1.

Purpose of the Cummins 4012485 Flywheel

The Cummins 4012485 Flywheel serves to store rotational energy and smooth engine operation in commercial trucks. By maintaining consistent rotational speed, it ensures that the engine operates efficiently and reduces the strain on other components. This flywheel plays a role in balancing the engine’s power delivery, which is particularly important in heavy-duty applications where consistent performance is crucial 2.

Key Features

The Cummins 4012485 Flywheel is characterized by its robust design and high-quality materials. It is constructed using durable materials that can withstand the rigors of heavy-duty use. The flywheel features a balanced design to ensure smooth operation and minimize vibrations. Additionally, it is engineered to integrate seamlessly with Cummins engines, enhancing overall performance and reliability 3.

Benefits

The Cummins 4012485 Flywheel offers several advantages, including improved engine efficiency, enhanced durability, and reliable performance under heavy-duty conditions. Its design contributes to smoother engine operation, reducing wear on other components and extending the lifespan of the engine. The flywheel’s ability to store and release rotational energy efficiently also contributes to better fuel economy and overall engine performance 4.

Installation and Integration

Proper installation of the Cummins 4012485 Flywheel is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure it is properly aligned and balanced. Careful attention to torque specifications and alignment is necessary to prevent issues such as vibrations or uneven wear. Integrating the flywheel with the engine system requires precision to maintain the engine’s balance and efficiency 5.

Troubleshooting and Maintenance

Common issues with the Cummins 4012485 Flywheel may include vibrations, uneven wear, or failure to engage properly with the clutch. Regular inspection and maintenance are recommended to identify and address these issues promptly. Maintenance tips include checking for proper alignment, ensuring the flywheel is free of debris, and verifying that all connections are secure. Timely maintenance helps ensure the flywheel continues to operate efficiently and extends its service life 6.

Performance Enhancements

The Cummins 4012485 Flywheel contributes to overall engine performance by enhancing torque, acceleration, and fuel efficiency. Its design allows for better energy storage and release, which translates to smoother power delivery and improved drivability. The flywheel’s role in maintaining consistent rotational speed also helps the engine operate more efficiently, leading to better performance in various driving conditions 7.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engines, Cummins has established a strong reputation for delivering durable and efficient solutions for commercial trucking. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry 8.

Role of Part 4012485 Flywheel in Engine Systems

The flywheel, specifically part 4012485, is integral to the operation of various engine systems. It serves as a pivotal component in the engine’s rotational energy storage and transfer mechanism. When the engine’s pistons move, they generate rotational force, which the flywheel stores as kinetic energy. This stored energy is then utilized to smooth out the power delivery between the engine’s combustion cycles, ensuring consistent operation.

In conjunction with the crankshaft, the flywheel helps maintain engine momentum. As the crankshaft converts the linear motion of the pistons into rotational motion, the flywheel’s mass and inertia assist in stabilizing this rotation. This stability is essential for the efficient operation of the engine, particularly during the phases when the pistons are not actively firing.

The flywheel also plays a significant role in the operation of the clutch system. In manual transmission vehicles, the flywheel is directly engaged with the clutch disc. When the clutch pedal is depressed, the pressure plate disengages from the flywheel, allowing the driver to shift gears smoothly. Upon releasing the clutch pedal, the flywheel re-engages with the clutch disc, transferring engine power to the transmission.

Furthermore, the flywheel is often equipped with ring gears that mesh with the starter motor’s pinion gear during engine start-up. This interaction allows the starter motor to crank the engine, initiating the combustion process 9.

Conclusion

The Cummins 4012485 Flywheel is a vital component that enhances the efficiency and reliability of Cummins engines. Its robust design, high-quality materials, and precise engineering ensure smooth operation, improved engine performance, and extended lifespan. Proper installation, regular maintenance, and understanding its role in the engine system are essential for maximizing the benefits of this part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 3666120, QSK19.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 3666120, QSK19.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 3666120, QSK19.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 3666120, QSK19.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.