This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

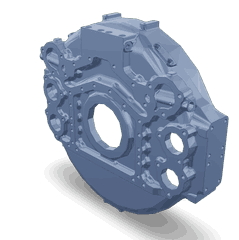

The Cummins 4016923 Flywheel Housing is a component designed for use in heavy-duty trucks. It plays a role in the engine system, contributing to the overall performance and durability of the vehicle. Understanding its purpose and significance can help mechanics and engineers maintain and optimize truck engines effectively.

Basic Concepts of Flywheel Housing

A flywheel housing is an enclosure that houses the flywheel, a heavy rotating disc that stores rotational energy and smooths out the delivery of power from the engine to the transmission. The housing protects the flywheel and clutch from external elements and contains the clutch mechanism. It interacts closely with the flywheel, clutch, and other engine components to ensure efficient power transmission 1.

Purpose of the 4016923 Flywheel Housing

The Cummins 4016923 Flywheel Housing provides a secure and protected environment for the flywheel and clutch assembly. It contributes to engine performance by ensuring that the flywheel operates smoothly and efficiently, which in turn helps maintain consistent power delivery. Additionally, the housing helps in reducing vibrations and noise, enhancing the overall durability and reliability of the engine system 2.

Key Features

This Cummins part is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty truck operation. Key features include a robust design that provides excellent protection for the flywheel and clutch, precise engineering to ensure proper fit and function, and a finish that resists corrosion and wear. These characteristics enhance the housing’s functionality and longevity 3.

Benefits

The advantages of using the Cummins 4016923 Flywheel Housing include improved engine efficiency due to reduced friction and better power transmission. It also contributes to reduced wear and tear on the flywheel and clutch, leading to longer component life. Additionally, the housing enhances overall engine performance by ensuring smooth and consistent operation of the flywheel and clutch system 4.

Installation Process

Proper installation of the Cummins 4016923 Flywheel Housing involves several steps. First, ensure the engine is cool and the vehicle is securely supported. Remove the old housing, if present, and inspect the mating surfaces for cleanliness and damage. Position the new housing over the flywheel and clutch, ensuring it aligns correctly with the engine block. Secure it in place using the appropriate fasteners, following the manufacturer’s torque specifications. Finally, perform a thorough inspection to confirm that all components are properly installed and functioning as intended 5.

Common Issues and Troubleshooting

Common problems associated with flywheel housings include leaks, excessive wear, and misalignment. To address these issues, regularly inspect the housing for signs of damage or wear. Ensure all fasteners are tight and the housing is properly aligned with the engine block. If leaks are detected, check the gaskets and seals for wear and replace them if necessary. Misalignment issues may require re-positioning or replacing the housing to ensure proper function 6.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4016923 Flywheel Housing, regular maintenance is crucial. Inspect the housing during routine engine checks for signs of wear, corrosion, or damage. Clean the housing and surrounding areas to prevent the buildup of dirt and debris. Replace gaskets and seals as needed to maintain a secure fit. Following these maintenance practices will help ensure the housing continues to perform effectively over time 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly for its heavy-duty truck components. The company is known for its commitment to quality, innovation, and customer satisfaction, providing reliable and high-performance products to meet the demands of various industries 8.

Role of Part 4016923 Flywheel Housing in Engine Systems

The 4016923 Flywheel Housing is an integral component in the assembly and operation of engine systems. It securely encases the flywheel, which is a heavy, rotating disk that stores rotational energy and smooths out the power delivery from the engine’s combustion cycles.

When installed, the Flywheel Housing aligns precisely with the engine block, ensuring a stable and vibration-free connection. This housing is designed to accommodate the flywheel’s movement while protecting it from external contaminants and damage.

The housing also interfaces with the clutch system, where the pressure plate and clutch disc are mounted. This setup allows for efficient transfer of power from the engine to the transmission. Additionally, the Flywheel Housing often includes mounting points for the starter motor, which engages with the flywheel to start the engine 9.

Conclusion

The Cummins 4016923 Flywheel Housing is a vital component in heavy-duty truck engines, contributing to engine performance, durability, and reliability. Proper installation, regular maintenance, and understanding its role in the engine system are essential for ensuring optimal operation and longevity of the vehicle.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023.

↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023.

↩ -

Operation and Maintenance Manual, Bulletin Number 5411258, Cummins Inc.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023.

↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023.

↩ -

Operation and Maintenance Manual, Bulletin Number 5411258, Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.