This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

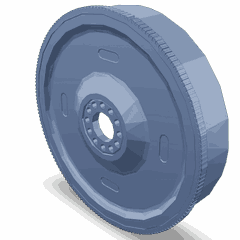

The Cummins 4100783 Flywheel is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its purpose is to store rotational energy and contribute to the smooth functioning of the engine. Understanding the flywheel’s function and significance is important for maintaining and optimizing the performance of commercial trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy. It consists of a heavy disk attached to a rotating shaft, designed to resist changes in rotational speed. Within an engine system, the flywheel serves multiple functions. It smooths out the power delivery from the engine by storing energy during the power stroke and releasing it during the other strokes. This results in a more consistent engine operation and reduces vibrations. Additionally, the flywheel engages with the starter motor to crank the engine during startup and connects to the transmission to transfer power to the vehicle’s wheels 1.

Purpose of the 4100783 Flywheel

This Cummins part is specifically engineered to enhance the operation of trucks equipped with Cummins engines. It plays a role in storing rotational energy, which helps in maintaining a consistent engine speed and reducing vibrations. This contributes to improved engine performance and fuel efficiency. By ensuring smooth power delivery, the flywheel also aids in the overall operation of the vehicle, making it a vital component in the drivetrain system 2.

Key Features

The 4100783 is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the demanding conditions of commercial truck operations. The flywheel features a balanced design to minimize vibrations and ensure smooth operation. Additionally, it is constructed from durable materials that offer resistance to wear and tear, contributing to its longevity. The engineering considerations in its development focus on optimizing performance, durability, and compatibility with Cummins engines 3.

Benefits

This part offers several benefits that enhance the operation of commercial trucks. It contributes to improved engine performance by ensuring smooth power delivery and reducing vibrations. This results in enhanced fuel efficiency, as the engine operates more efficiently with consistent power output. Additionally, the durability of the flywheel means it can withstand the rigors of heavy-duty use, providing long-term reliability for truck operators and fleet managers 4.

Installation and Compatibility

Proper installation of the 4100783 is important to ensure optimal performance. It is designed to be compatible with specific Cummins engine models, ensuring a precise fit and function within the engine system. When installing the flywheel, it is important to follow manufacturer guidelines to ensure it is properly aligned and secured. This includes any necessary preparations, such as cleaning the mating surfaces and inspecting for any damage that could affect performance 5.

Maintenance and Troubleshooting

Maintaining the 4100783 is important to ensure its optimal performance and longevity. Regular inspections for signs of wear or damage are recommended. Additionally, ensuring that the flywheel is properly lubricated and that all connections are secure can help prevent issues. Common problems with flywheels may include vibrations, difficulty starting the engine, or transmission issues. Troubleshooting these problems may involve checking for proper alignment, inspecting for wear, and ensuring all components are in good working condition 6.

Safety Considerations

When working with flywheels, including the 4100783 model, it is important to observe safety considerations. This includes using proper handling procedures to avoid injury from the heavy and rotating components. Safety equipment, such as gloves and eye protection, should be worn when performing maintenance or repairs. Additionally, being aware of potential hazards, such as the flywheel’s stored energy, can help prevent accidents during installation or removal 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry for quality and innovation, Cummins is committed to providing reliable and efficient solutions for its customers. The company’s expertise in engine technology is evident in the development and manufacturing of the 4100783, showcasing its dedication to enhancing the performance and reliability of commercial trucks.

Cummins Flywheel Part 4100783 Compatibility

The Cummins flywheel part number 4100783 is a critical component in the engine’s operation, ensuring smooth and efficient power transmission. This flywheel is designed to fit seamlessly with several Cummins engine models, enhancing their performance and reliability.

QSK60 Series

The QSK60 series engines, including the QSK60 CM500 and QSK60 CM850 MCRS, benefit significantly from the use of the 4100783 flywheel. This part is engineered to match the specific torque and rotational demands of these engines, ensuring optimal performance across various applications.

- QSK60 CM500: This engine model is designed for heavy-duty applications, and the 4100783 flywheel provides the necessary balance and strength to handle the high loads and stresses.

- QSK60 CM850 MCRS: This variant is equipped with the MCRS (Modular Common Rail System) technology, enhancing fuel efficiency and power output. The 4100783 flywheel complements these features by maintaining consistent engine speed and smooth power delivery.

QSK60G

The QSK60G engine is another model that integrates well with the 4100783 flywheel. This engine is known for its robust construction and high performance, making it suitable for demanding industrial and marine applications. The flywheel ensures that the engine operates smoothly, reducing wear and tear and extending the engine’s lifespan.

Installation and Integration

The installation of the 4100783 flywheel in these engines is straightforward, thanks to its precise engineering and compatibility with the QSK60 series. Technicians can expect a seamless fit, minimizing downtime and ensuring that the engine returns to optimal performance quickly. The flywheel’s design allows for easy integration with the engine’s existing components, facilitating a hassle-free installation process.

Role of Part 4100783 Flywheel in Engine Systems

The flywheel, identified by part number 4100783, is integral to the operation of various engine systems. It serves as a pivotal component in the engine’s rotational energy storage and transfer mechanism.

In the starter system, the flywheel engages with the starter motor’s pinion gear during engine start-up. This engagement allows the starter motor to turn the flywheel, which in turn rotates the crankshaft, initiating the engine’s combustion cycle.

Within the clutch system, the flywheel plays a significant role. It is connected to the pressure plate, which is part of the clutch assembly. When the clutch pedal is depressed, the pressure plate disengages from the flywheel, allowing the driver to change gears without interrupting the engine’s rotation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission.

In the transmission system, the flywheel ensures smooth power delivery. Its inertia helps maintain rotational momentum, which is essential for consistent gear changes and overall drivetrain performance.

The flywheel also contributes to the engine’s balance and vibration control. Its mass helps counteract the reciprocating motion of the pistons, reducing vibrations and ensuring smoother operation.

Furthermore, in the exhaust system, the flywheel’s consistent rotational speed aids in the efficient expulsion of exhaust gases. This is particularly important in engines with balanced exhaust systems, where consistent engine speed is necessary for optimal performance.

Lastly, in the fuel system, the flywheel’s stable rotation ensures that the fuel injection timing remains accurate. This is vital for maintaining the correct air-fuel mixture, which is essential for efficient combustion and overall engine performance.

Conclusion

The Cummins 4100783 Flywheel is a critical component in the operation of commercial trucks, contributing to smooth engine performance, efficient power transmission, and overall vehicle reliability. Its robust design, compatibility with specific Cummins engine models, and the benefits it offers make it an essential part of the drivetrain system. Proper installation, maintenance, and adherence to safety considerations are important to ensure the optimal performance and longevity of this part.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Cummins Inc. Service Manual (5504567).

↩ -

Cummins Inc. Service Manual (5504567).

↩ -

Cummins Inc. Service Manual (5504567).

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.