4313341

Flywheel Housing Seal

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

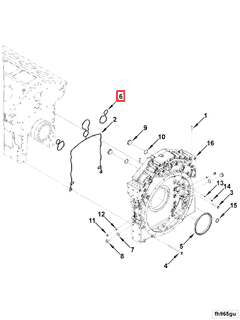

The Flywheel Housing Seal, identified by Part #4313341, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This seal is integral to the operation of heavy-duty trucks, ensuring the efficient and reliable performance of the engine system 1.

Function and Operation

The Flywheel Housing Seal operates within the truck’s engine system by maintaining the integrity of the flywheel housing. It plays a role in preserving the pressure within the system and preventing leaks that could compromise engine performance. The seal is positioned to interface with moving parts, ensuring a tight fit that withstands the operational stresses of the engine 2.

Purpose of the Flywheel Housing Seal

The primary role of the Flywheel Housing Seal is to provide a secure seal for the flywheel housing. This function is vital for maintaining the operational environment within the engine, ensuring that no contaminants enter and that pressure is consistently maintained. The seal contributes to the overall efficiency and reliability of the truck’s engine system.

Key Features

The Flywheel Housing Seal is characterized by several key features that enhance its performance. These include a durable material composition designed to resist wear and tear, precise design elements that ensure a snug fit, and unique attributes such as reinforced edges that provide additional strength and longevity. These features collectively contribute to the seal’s effectiveness in demanding engine environments.

Benefits

The advantages provided by the Flywheel Housing Seal include improved engine efficiency through consistent pressure maintenance, reduced maintenance needs due to its durable construction, and enhanced durability that ensures long-term performance. These benefits contribute to the overall reliability and efficiency of the truck’s engine system.

Installation Process

Proper installation of the Flywheel Housing Seal involves several steps to ensure optimal performance. It is important to follow best practices, such as ensuring the mating surfaces are clean and free of debris before installation. Common pitfalls to avoid include over-tightening, which can damage the seal, and improper alignment, which can lead to leaks. Careful attention to these details during installation will help ensure the seal functions effectively.

Troubleshooting Common Issues

Frequent problems associated with the Flywheel Housing Seal may include leaks or failure to maintain pressure. Diagnostic steps to identify these issues involve inspecting the seal for signs of wear or damage and checking the installation for proper alignment and fit. Solutions may range from re-sealing or replacing the seal to addressing any underlying issues that may have contributed to the failure.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Flywheel Housing Seal. These include periodic inspections for signs of wear or damage, cleaning the mating surfaces to prevent contamination, and ensuring that the seal remains properly aligned and fitted. Adhering to these maintenance tips will help maintain the seal’s effectiveness over time.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to excellence, Cummins has established itself as a trusted provider of engine components and systems, including the Flywheel Housing Seal. The company’s product range and reputation underscore its position as a key player in the industry 3.

Cummins Flywheel Housing Seal (Part 4313341) Compatibility

The Cummins Flywheel Housing Seal (Part 4313341) is designed to ensure the integrity of the flywheel housing in various engine models. This seal is engineered to fit seamlessly with the following Cummins engines:

- QSK95 CM2350 K111

- QSK95 CM2350 K113

These engines are part of the Cummins QSK series, known for their robust performance and reliability in demanding applications. The flywheel housing seal plays a vital role in maintaining the engine’s operational efficiency by preventing oil leaks and ensuring that the flywheel housing remains sealed against contaminants. This seal is specifically designed to withstand the high temperatures and pressures inherent in these engine models, ensuring longevity and consistent performance.

Role of Part 4313341 Flywheel Housing Seal in Engine Systems

This Cummins part is an essential component in maintaining the integrity and efficiency of engine systems. It is specifically designed to fit within the flywheel housing kit, ensuring a secure and leak-free environment for the flywheel and associated components.

Integration with Flywheel Housing Kit

When installed within the flywheel housing kit, the 4313341 seal plays a significant role in preventing oil and other lubricants from escaping. This containment is vital for maintaining proper lubrication levels, which in turn ensures smooth operation of the flywheel and connected parts. The seal’s precise fit within the housing helps in reducing friction and wear, contributing to the overall longevity of the engine system.

Interaction with Housing

The housing itself is a critical enclosure that protects the flywheel and other internal components from external contaminants. The 4313341 seal enhances this protective function by creating a barrier that prevents dirt, debris, and moisture from entering the housing. This barrier is essential for maintaining the cleanliness and efficiency of the internal components, thereby supporting the engine’s performance and reliability.

Relationship with Flywheel

The flywheel is a key component in the engine system, responsible for storing rotational energy and smoothing out the power delivery from the engine’s cylinders. The 4313341 seal ensures that the flywheel operates within a well-lubricated and clean environment. By maintaining the integrity of the lubricants and preventing contamination, the seal indirectly supports the flywheel’s ability to perform its function effectively, leading to consistent engine operation and reduced maintenance requirements.

Conclusion

In summary, the 4313341 Flywheel Housing Seal is a vital element in the engine system, working in conjunction with the flywheel housing kit, housing, and flywheel to ensure optimal performance and durability. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to maximize the effectiveness of this part in heavy-duty truck engines.

-

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.