This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

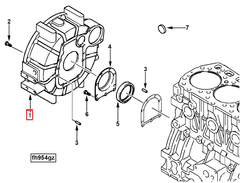

The Flywheel Housing 4900475 by Cummins is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by housing the flywheel, which is integral to the engine’s function. This housing ensures the flywheel operates within a protected environment, contributing to the overall efficiency and reliability of the truck’s engine system.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that surrounds the flywheel, a heavy rotating disc that stores rotational energy. This housing plays a role in the engine system by securing the flywheel in place and shielding it from external elements. It interacts closely with other components such as the clutch and transmission, facilitating the smooth transfer of power from the engine to the drivetrain.

Purpose of the Flywheel Housing

The 4900475 Flywheel Housing is designed to support the flywheel and ensure its proper function within the engine system. By providing a secure and stable environment for the flywheel, this housing contributes to the efficient transmission of power. It also plays a role in maintaining the alignment and integrity of the flywheel, which is vital for the consistent operation of the truck.

Key Features

The 4900475 Flywheel Housing is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty use. Its design incorporates features that enhance performance and longevity, such as precise engineering for optimal fit and function. Additionally, the housing may include elements that improve heat dissipation and reduce noise, contributing to a more efficient and quieter engine operation.

Benefits of Using the Flywheel Housing

Utilizing the 4900475 Flywheel Housing offers several advantages. It contributes to improved engine efficiency by ensuring the flywheel operates under optimal conditions. The housing’s durable construction enhances the engine’s reliability, allowing it to perform consistently under heavy-duty conditions. Furthermore, its design may reduce maintenance requirements, offering long-term value to truck operators.

Installation Process

Installing the 4900475 Flywheel Housing requires careful attention to detail to ensure proper fit and function. The process involves securing the housing around the flywheel, ensuring all fasteners are tightened to the manufacturer’s specifications. It is important to verify that the housing is aligned correctly with the clutch and transmission components to facilitate smooth power transmission. Following the manufacturer’s guidelines during installation is recommended to achieve the best results.

Common Issues and Troubleshooting

Flywheel housings may encounter issues such as leaks, cracks, or misalignment over time. These problems can affect the performance of the engine and transmission system. Troubleshooting these issues involves inspecting the housing for signs of damage or wear, checking the alignment with other components, and ensuring all fasteners are secure. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s engine system.

Maintenance Tips

Regular maintenance of the 4900475 Flywheel Housing is important for prolonging its lifespan and ensuring optimal performance. This includes routine inspections for signs of wear or damage, cleaning the housing to remove any debris or buildup, and following the manufacturer’s recommendations for replacement or repair. Adhering to these maintenance practices can help prevent issues and ensure the housing continues to function effectively.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a history of innovation and excellence, Cummins has established a reputation for reliability and performance. The 4900475 Flywheel Housing is part of Cummins’ commitment to providing durable and efficient solutions for the demanding needs of commercial trucking.

Compatibility with Cummins Engines

The Cummins part 4900475, known as the Flywheel Housing, is designed to fit seamlessly with a range of engine models. Specifically, this part is compatible with the A1400, A1700, A2000, and A2300 engines. The Flywheel Housing is a critical component that houses the flywheel, which plays a pivotal role in the engine’s operation by maintaining rotational momentum and facilitating the smooth engagement of the starter motor.

For the A1400 and A1700 engines, the Flywheel Housing is engineered to provide a robust and reliable connection, ensuring that the flywheel operates efficiently within its designated parameters. These engines, known for their reliability and performance, benefit from the precision engineering of the Flywheel Housing, which helps in maintaining the integrity of the engine’s operation.

Similarly, the A2000 and A2300 engines also utilize the Flywheel Housing part 4900475. These engines, which are part of a higher performance and power output range, require a Flywheel Housing that can withstand the increased stresses and demands placed upon it. The compatibility of this part with these engines ensures that the flywheel can function optimally, contributing to the overall efficiency and longevity of the engine.

Role of the Flywheel Housing in Engine Systems

The flywheel housing, identified by part number 4900475, is an integral component in the assembly and operation of engine systems. It serves as the enclosure for the flywheel, which is a heavy rotating disc that stores rotational energy and smooths out the delivery of power from a motor to its load.

In the context of engine systems, the flywheel housing is designed to securely hold the flywheel in place while allowing it to rotate freely. This housing is typically bolted to the engine block, ensuring a stable connection that can withstand the forces generated during engine operation.

The flywheel housing also interfaces with the clutch system. In manual transmission vehicles, it houses the pressure plate and clutch disc, which are essential for transmitting power from the engine to the transmission. The housing must be precisely machined to ensure a proper fit and alignment with these components, which is vital for efficient power transfer and smooth gear changes.

Furthermore, the flywheel housing often incorporates mounting points for the starter motor. The starter motor engages with the flywheel to crank the engine during startup. The housing must provide a robust and accurate mounting surface to ensure reliable starter motor operation.

In diesel engines, the flywheel housing may also accommodate the injection pump drive mechanism. This setup requires the housing to have additional features such as gears or splines to drive the injection pump in sync with the engine’s rotation.

Overall, the flywheel housing plays a significant role in maintaining the structural integrity and functional efficiency of the engine system. Its design and construction are tailored to endure the high stresses and dynamic loads encountered during engine operation, ensuring reliable performance and longevity of the engine components it supports.

Conclusion

The 4900475 Flywheel Housing by Cummins is a critical component in the operation of commercial truck engines. Its role in securing and protecting the flywheel contributes to the engine’s efficiency and reliability. Proper installation, maintenance, and troubleshooting are essential to ensure the housing performs optimally and supports the engine’s function effectively.

References:

: Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

: Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

: Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.