This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

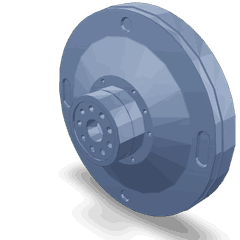

The Cummins 4913615 Flywheel is a critical component for commercial trucks, essential for the smooth operation of these vehicles. Its primary role is to store rotational energy, contributing to the engine’s consistent performance. Understanding the flywheel’s function and importance is key to maintaining and enhancing the performance of commercial trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy, consisting of a heavy disc attached to the engine’s crankshaft. As the engine operates, the flywheel rotates, storing energy that smooths power delivery between engine firing cycles. This results in a more stable engine operation, reducing vibrations and ensuring a smoother drive 1.

Purpose of the Cummins 4913615 Flywheel

The Cummins 4913615 Flywheel serves multiple functions within the engine system of a truck. It stores rotational energy, maintaining momentum between the engine’s power strokes. This stored energy helps keep the engine running smoothly, even when power delivery is not continuous. Additionally, the flywheel plays a role in the truck’s clutch system, facilitating smooth gear changes and enhancing drivability 2.

Key Features

This Cummins part is engineered with several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and reliability under the demanding conditions of commercial truck operation. The design includes precise balancing to minimize vibrations and smooth out engine operation. It may also incorporate advanced materials or coatings to improve wear resistance and longevity 3.

Benefits

The Cummins 4913615 Flywheel offers several advantages. It contributes to improved engine efficiency by ensuring smooth power delivery and reducing the load on the engine during operation. The flywheel’s durable construction enhances the overall reliability of the truck’s engine system. Furthermore, its role in the clutch system ensures smoother gear changes, contributing to a more comfortable and efficient driving experience.

Installation and Integration

Proper installation of the Cummins 4913615 Flywheel is essential for ensuring optimal performance. The installation process involves aligning the flywheel with the engine’s crankshaft and securing it in place. It is important to follow manufacturer guidelines to ensure correct torque specifications and alignment. Additionally, any necessary preparations, such as cleaning the mating surfaces and inspecting for damage, should be performed before installation.

Common Issues and Troubleshooting

Flywheels can encounter several common issues, including wear, cracking, or imbalance. Symptoms of flywheel problems may include difficulty in shifting gears, unusual vibrations, or a noticeable decrease in engine performance. Troubleshooting steps involve inspecting the flywheel for signs of damage, checking the alignment and balance, and ensuring that all mounting bolts are properly torqued. Addressing these issues promptly can prevent further damage and ensure the continued smooth operation of the engine.

Maintenance Tips

Regular maintenance of the Cummins 4913615 Flywheel is important for ensuring its longevity and performance. This includes periodic inspections for signs of wear or damage, ensuring that the flywheel remains properly balanced, and checking the condition of the clutch system. Following the manufacturer’s recommended maintenance schedule and addressing any issues promptly can help maintain the flywheel’s performance and extend its service life.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable engines and components. The company’s commitment to innovation and customer satisfaction has made it a trusted name in the automotive and heavy-duty truck industries.

The Cummins part 4913615, a Flywheel, is designed to be compatible with a range of Cummins engines, including the K19, QSK19, CM850, and MCRS. This flywheel is integral to the engine’s operation, ensuring smooth and efficient power transmission from the engine to the transmission or other mechanical systems.

For the K19 and QSK19 engines, the flywheel plays a crucial role in maintaining the balance and stability of the engine during operation. Its design allows for effective engagement and disengagement of the clutch, which is essential for smooth gear changes and overall drivability.

In the CM850 and MCRS engines, the flywheel’s robust construction and precise engineering are tailored to handle the specific demands of these engines. It ensures that the engine can operate at high speeds and under heavy loads without compromising performance or reliability.

The compatibility of the Cummins part 4913615 across these engines highlights its versatility and the high standards set by Cummins in manufacturing engine components. This flywheel is engineered to meet the rigorous requirements of each engine model, ensuring optimal performance and longevity.

Role of Part 4913615 Flywheel in Engine Systems

The flywheel, specifically part 4913615, is integral to the operation of several engine systems. It serves as a pivotal component in the interface between the engine and the transmission, ensuring smooth power delivery.

Interaction with the Clutch System

When the engine is running, the flywheel is directly connected to the crankshaft, allowing it to spin at the same rate. During gear changes, the clutch disengages from the flywheel, permitting the driver to shift gears without interrupting the engine’s operation. The flywheel’s mass helps to stabilize the engine’s rotational speed, reducing vibrations and ensuring a consistent power transfer to the transmission.

Contribution to the Starter System

During engine start-up, the flywheel engages with the starter motor. The starter motor’s pinion gear meshes with the flywheel’s ring gear, spinning the flywheel and, consequently, the crankshaft. This action initiates the engine’s combustion cycle. The flywheel’s substantial mass aids in overcoming the engine’s inertia, facilitating a smoother start.

Influence on the Drivetrain

Once the engine is running and the clutch is engaged, the flywheel transmits power from the engine to the transmission and ultimately to the drivetrain. Its design helps in managing the torque fluctuations produced by the engine’s combustion cycles, providing a more stable power delivery to the wheels.

Impact on the Vibration Dampening System

The flywheel also plays a role in the vibration dampening system. Its mass helps to absorb and smooth out the vibrations generated by the engine’s reciprocating parts. This function is particularly important in ensuring a comfortable driving experience and prolonging the lifespan of other engine components.

Relationship with the Flywheel Housing

The flywheel is housed within the flywheel housing, which is part of the engine block. This housing not only protects the flywheel but also aligns it correctly with the clutch and starter motor. The precise fit and alignment are essential for the efficient operation of the engine systems.

Conclusion

In summary, the Cummins 4913615 Flywheel is a multifaceted component that interacts with various engine systems, contributing to the overall performance and reliability of the engine. Its role in storing rotational energy, facilitating smooth gear changes, and ensuring stable power delivery is crucial for the efficient operation of commercial trucks.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.