This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

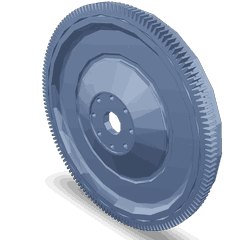

The Cummins 4929860 Flywheel is a component designed to enhance the operation of commercial trucks. Its purpose is to store rotational energy and contribute to the smooth functioning of the engine. This flywheel is significant in maintaining the efficiency and performance of truck engines, playing a role in the overall drivetrain system.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy. It operates on the principle of inertia, which allows it to resist changes in rotational speed. Within an engine system, the flywheel smooths out the power delivery from the engine to the transmission, ensuring consistent operation despite the intermittent power pulses from the combustion process. This results in a more stable and efficient engine performance 1.

Purpose of the 4929860 Flywheel

The Cummins 4929860 Flywheel is specifically engineered to enhance the operation of trucks. It contributes to engine performance by maintaining consistent rotational energy, which aids in smoother gear changes and reduces strain on the drivetrain. Additionally, it plays a role in improving fuel efficiency by ensuring that the engine operates within optimal parameters. The flywheel also supports the overall functionality of the drivetrain by providing a stable platform for power transmission 2.

Key Features

The Cummins 4929860 Flywheel is characterized by its robust design and high-quality materials. It is constructed to ensure precise balance, which is crucial for minimizing vibrations and ensuring smooth operation. The flywheel’s weight is carefully calibrated to provide the necessary inertia without adding excessive load to the engine. Its durability is enhanced through the use of premium materials that resist wear and corrosion, ensuring long-term performance 3.

Benefits

Using the Cummins 4929860 Flywheel offers several advantages. It contributes to improved engine performance by providing consistent rotational energy, which leads to smoother operation and better power delivery. Enhanced fuel efficiency is another benefit, as the flywheel helps maintain optimal engine speed and reduces the need for frequent adjustments. Additionally, it reduces wear on other components by ensuring stable power transmission, leading to increased reliability and longevity of the drivetrain.

Installation Process

Installing the Cummins 4929860 Flywheel requires careful attention to detail. The process involves removing the old flywheel, ensuring the engine and transmission are properly aligned, and securely mounting the new flywheel. It is important to use the correct tools and follow best practices to avoid potential issues such as misalignment or improper torque. Careful inspection of the installation area for any debris or damage is also crucial to ensure a successful installation.

Troubleshooting Common Issues

Common issues with the Cummins 4929860 Flywheel may include vibration, noise, or failure to engage properly. Vibration can often be traced to imbalance or misalignment, which may require re-evaluation of the installation process. Noise could indicate wear or damage to the flywheel or related components, necessitating a thorough inspection. Failure to engage properly might be due to clutch issues or misalignment, requiring diagnostic steps to identify and address the root cause.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 4929860 Flywheel, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the flywheel and surrounding components to prevent buildup of debris, and ensuring proper alignment and balance. If significant wear is detected, considering replacement may be necessary to maintain engine efficiency and reliability.

About Cummins

Cummins Inc. is a renowned manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company has a long history of producing high-quality components, including engines and related parts. Cummins is committed to innovation and excellence, contributing significantly to engine technology and the commercial truck market. Their components are known for reliability, performance, and durability, making them a preferred choice for many truck operators and manufacturers.

Compatibility

The Cummins part number 4929860, a Flywheel, is designed to fit a variety of Cummins engines, ensuring smooth engine operation and efficient power delivery. This flywheel is compatible with the following engines:

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

This flywheel is engineered to meet the specific requirements of these engines, providing durability and reliability in various applications. It is crucial for the proper functioning of the engine, as it helps in maintaining the rotational speed and energy of the engine’s crankshaft.

Role of Part 4929860 Flywheel in Engine Systems

The flywheel, specifically part 4929860, is an integral component in the operation of engine systems, serving multiple functions that contribute to the overall efficiency and performance of the engine.

Energy Storage and Smooth Operation

One of the primary roles of the flywheel is to store rotational energy. As the engine’s crankshaft rotates, the flywheel accumulates kinetic energy. This stored energy is then used to maintain the engine’s momentum between power strokes, ensuring a smooth and consistent operation. Without the flywheel, the engine would experience significant vibrations and would be less efficient due to the irregular power delivery.

Clutch Engagement

In manual transmission vehicles, the flywheel plays a key role in the clutch system. When the clutch pedal is depressed, the pressure plate is disengaged from the flywheel, allowing the driver to shift gears smoothly. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring power from the engine to the transmission. The flywheel’s mass and inertia are essential for this process, as they help to manage the torque and ensure a seamless transfer of power.

Starter Motor Assistance

During engine start-up, the flywheel assists the starter motor in cranking the engine. The starter motor engages with a ring gear attached to the flywheel, spinning it to initiate the combustion process. The flywheel’s design and material properties are optimized to withstand the stresses induced during this process, ensuring reliable starts.

Vibration Dampening

The flywheel also acts as a vibration dampener. By absorbing and smoothing out the pulses of torque generated by the engine’s combustion cycles, the flywheel reduces vibrations that could otherwise be transmitted to the drivetrain and chassis. This not only enhances driver comfort but also contributes to the longevity of engine components by minimizing wear and stress.

Balancing the Engine

In many engine designs, the flywheel helps to balance the rotating assembly. Its mass is strategically positioned to counteract the forces generated by the reciprocating components, such as the pistons and connecting rods. This balancing effect is vital for maintaining the engine’s stability and reducing harmful vibrations.

Integration with Other Components

The flywheel interacts with several other engine components, including the crankshaft, clutch assembly, and starter motor. Its design must be compatible with these parts to ensure optimal performance and durability. For instance, the flywheel must be precisely machined to mate correctly with the crankshaft and must be constructed from materials that can withstand the thermal and mechanical stresses of engine operation.

Conclusion

In summary, the Cummins 4929860 Flywheel is a multifaceted component that enhances the functionality and reliability of engine systems through energy storage, smooth operation, clutch engagement, starter motor assistance, vibration dampening, and engine balancing. Its robust design, precise balance, and compatibility with various Cummins engines make it a critical part for maintaining engine efficiency and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.