This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

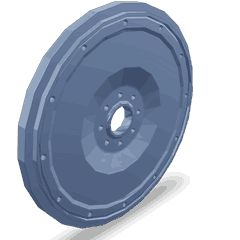

The Cummins 4933615 Flywheel is a component designed for use in heavy-duty trucks. Its purpose is to store rotational energy and smooth out engine operation, contributing to the overall efficiency and performance of the vehicle. Understanding its function and significance is key to maintaining and optimizing the operation of heavy-duty trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy. It consists of a heavy circular disk attached to a rotating shaft. When the engine produces power, the flywheel stores this energy and releases it during the power stroke, helping to maintain a consistent rotational speed. This mechanism smooths out the engine’s operation, reducing vibrations and ensuring a steady power delivery 1.

Purpose of the 4933615 Flywheel

This Cummins part plays a specific role in the operation of heavy-duty trucks. It is designed to enhance engine performance by storing and releasing rotational energy efficiently. This contributes to smoother engine operation, improved fuel efficiency, and overall vehicle performance. The flywheel’s design allows it to withstand the high stresses and demands of heavy-duty applications, ensuring reliable operation under various conditions 2.

Key Features

This part is characterized by its robust design and high-quality materials. It is constructed from durable materials to ensure longevity and performance. The flywheel features a balanced design to minimize vibrations and a precise fit to ensure compatibility with the engine. These features distinguish it from other flywheels, providing enhanced performance and reliability 3.

Benefits

Using the 4933615 Flywheel offers several benefits. It contributes to improved engine performance by ensuring smooth and consistent power delivery. The flywheel enhances fuel efficiency by optimizing the engine’s rotational energy usage. Additionally, its durable construction increases the longevity of the component, reducing the need for frequent replacements and maintenance. These benefits contribute to the overall operation and maintenance of heavy-duty trucks 4.

Installation Process

Installing this part requires careful attention to detail. The process involves removing the old flywheel, cleaning the mating surfaces, and installing the new flywheel with the correct torque specifications. Proper installation is vital to ensure optimal performance and longevity. Following the manufacturer’s guidelines and using the appropriate tools will help achieve a successful installation 5.

Common Issues and Troubleshooting

Common issues with the 4933615 Flywheel may include vibration, noise, or failure to engage. These issues can often be traced to improper installation, wear and tear, or compatibility issues. Troubleshooting involves inspecting the flywheel for damage, ensuring proper installation, and addressing any underlying issues. Regular maintenance and inspections can help prevent these issues and ensure the flywheel operates smoothly 6.

Maintenance Tips

Maintaining the 4933615 Flywheel is crucial for ensuring optimal performance and longevity. Regular inspections should be conducted to check for signs of wear or damage. Cleaning the flywheel and its mating surfaces can prevent contamination and ensure a proper fit. Lubricating the flywheel’s mounting points can reduce friction and wear. Following these maintenance practices will help keep the flywheel in good condition 7.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality components and innovative technologies. With a strong reputation in the automotive industry, Cummins is committed to producing reliable and efficient parts for various applications. The company’s focus on innovation and quality ensures that its products, like the 4933615 Flywheel, meet the demanding requirements of heavy-duty trucks 8.

Cummins Flywheel Part 4933615 Compatibility

The Cummins flywheel part number 4933615 is designed to fit several engine models within the Cummins lineup. This part is integral to the engine’s operation, ensuring smooth and efficient power transmission from the engine to the transmission.

ISB/ISD6.7 CM2150 SN Engines

The ISB/ISD6.7 CM2150 SN engines are robust and reliable, commonly used in various heavy-duty applications. The flywheel part 4933615 is engineered to match the specific torque and rotational requirements of these engines, ensuring optimal performance and longevity.

ISBE CM2150 Engines

The ISBE CM2150 engines are another variant where the flywheel part 4933615 is applicable. These engines are known for their durability and efficiency, often used in industrial and commercial applications. The compatibility of this flywheel part ensures that the engine operates smoothly, maintaining its performance over time.

ISBE4 CM850 Engines

The ISBE4 CM850 engines, while different in specifications, also benefit from the use of the flywheel part 4933615. This part is designed to handle the unique demands of these engines, providing the necessary balance and power transmission to ensure the engine runs efficiently.

By using the flywheel part 4933615 across these engine models, users can expect consistent performance and reliability, making it a versatile component in the Cummins engine ecosystem.

Role of Part 4933615 Flywheel in Engine Systems

The flywheel, specifically part 4933615, is integral to the operation of various engine systems. It serves as a vital link between the engine and the transmission, ensuring smooth power transfer.

Interaction with the Clutch System

When the engine is running, the flywheel rotates, driven by the crankshaft. The clutch system engages with the flywheel to transmit engine power to the transmission. As the driver modulates the clutch pedal, the pressure plate either engages or disengages the clutch disc from the flywheel, allowing for gear changes without interrupting the engine’s operation 9.

Contribution to the Starting System

During engine start-up, the flywheel plays a significant role. The starter motor engages with the flywheel’s ring gear, spinning the engine to initiate combustion. The flywheel’s mass helps to store rotational energy, which aids in cranking the engine smoothly and efficiently 10.

Influence on the Drivetrain

Once the engine is running and the clutch is engaged, the flywheel continues to rotate, transferring power through the drivetrain. Its inertia helps maintain consistent rotational speed, reducing fluctuations that could otherwise lead to a rough-running engine 11.

Impact on the Exhaust System

The flywheel’s consistent rotation ensures that the engine’s reciprocating motion is converted into smooth rotational motion. This stability is essential for the efficient operation of the exhaust system, as it relies on consistent engine speed to expel exhaust gases effectively 12.

Relationship with the Fuel System

Although indirectly, the flywheel affects the fuel system’s performance. Consistent engine speed, maintained by the flywheel, ensures that the fuel injection system delivers fuel at the correct times, optimizing combustion efficiency and overall engine performance 13.

Effect on the Cooling System

Stable engine operation, facilitated by the flywheel, ensures that the cooling system functions effectively. Consistent engine speed helps maintain optimal coolant flow, preventing overheating and ensuring the engine operates within safe temperature ranges 14.

Interaction with the Ignition System

The flywheel’s uniform rotation is essential for the ignition system’s timing. It ensures that the spark plugs fire at the correct moments in the combustion cycle, contributing to efficient fuel burning and smooth engine operation 15.

Conclusion

In summary, the 4933615 Flywheel is a cornerstone component that interacts with multiple engine systems, ensuring seamless operation and efficient power transmission. Its robust design, compatibility with various Cummins engine models, and significant role in engine systems make it a critical part for maintaining and optimizing the performance of heavy-duty trucks.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.