This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

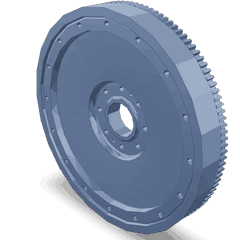

The Cummins 4934885 Flywheel is a component designed for use in commercial trucks, playing a significant role in the operation of these vehicles. Its purpose is to store rotational energy and contribute to the smooth functioning of the engine. Understanding its function and significance can provide valuable insights into the overall performance and efficiency of commercial trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing energy when the engine accelerates and releasing it when the engine decelerates. This mechanism smooths out engine operation, reducing fluctuations in speed and providing a stable power output. Flywheels are integral to the functioning of internal combustion engines, ensuring that the engine operates efficiently and reliably 1.

Purpose of the Cummins 4934885 Flywheel

This Cummins part is specifically engineered to enhance the performance of commercial truck engines. It plays a role in storing rotational energy, which helps to smooth out engine operation and maintain consistent power delivery. By doing so, it contributes to improved engine performance, better fuel efficiency, and enhanced overall drivetrain functionality. The flywheel’s design is tailored to meet the demanding requirements of commercial truck applications, ensuring reliable operation under various driving conditions 2.

Key Features

The 4934885 is characterized by several key features that set it apart from other flywheels. Its design incorporates high-quality materials that offer durability and resistance to wear. The flywheel is engineered to withstand the rigors of commercial truck use, providing long-lasting performance. Additionally, it features precise machining and balancing to ensure smooth operation and minimal vibration. The engineering considerations that went into its development focus on optimizing performance, durability, and compatibility with specific engine configurations 3.

Benefits

This part offers several benefits that translate to real-world advantages for truck operators and fleet managers. Improved engine performance is one of the primary benefits, as the flywheel helps to maintain consistent power delivery and smooth operation. Enhanced fuel efficiency is another significant advantage, as the flywheel’s ability to store and release rotational energy contributes to more efficient engine operation. Increased durability ensures that the flywheel can withstand the demands of commercial truck use, reducing the need for frequent replacements and maintenance. These benefits contribute to lower operating costs and improved reliability for fleet operations 4.

Installation and Compatibility

Proper installation of this part is crucial to ensure optimal performance and longevity. Guidelines for installation include ensuring that the flywheel is properly aligned with the engine and transmission, and that all mounting surfaces are clean and free of debris. Specific requirements may vary depending on the truck model and engine configuration, so it is important to consult the manufacturer’s instructions for detailed guidance. Compatibility with different truck models and engine configurations is an important consideration, ensuring that the flywheel functions correctly within the specific application 5.

Troubleshooting and Maintenance

Routine maintenance practices are important to ensure the optimal performance and longevity of this part. Regular inspections for signs of wear or damage can help identify potential issues before they become serious problems. Troubleshooting common issues may involve checking for proper alignment, ensuring that mounting surfaces are clean, and verifying that the flywheel is balanced correctly. Following manufacturer recommendations for maintenance and inspection intervals can help prevent issues and ensure reliable operation 6.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related components, with a reputation for innovation and quality. The company has a long history of providing reliable and high-performance solutions for a wide range of applications, including commercial trucks. Cummins’ commitment to innovation is evident in the design and development of components like the 4934885, which are engineered to meet the demanding requirements of commercial truck use. The company’s focus on quality and performance ensures that its products contribute to the efficient and reliable operation of commercial vehicles 7.

Cummins Flywheel Part 4934885 Compatibility

The Cummins flywheel part number 4934885 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This flywheel is engineered to work with the following Cummins engines:

QSM11 Engines

The QSM11 series engines benefit from the robust design of the 4934885 flywheel. This part is specifically tailored to match the QSM11’s power output and torque requirements, providing a smooth and efficient power transfer from the engine to the transmission.

CM570 Engines

Similarly, the CM570 engines are compatible with the 4934885 flywheel. This part ensures that the CM570 engines maintain their high performance and durability, crucial for applications that demand consistent power and reliability.

Grouping of Engines

The compatibility of the 4934885 flywheel with both the QSM11 and CM570 engines highlights its versatility and broad application range. Cummins has ensured that this flywheel part is designed to meet the specific needs of these engines, making it a reliable choice for maintenance and replacement purposes 8.

Role of Part 4934885 Flywheel in Engine Systems

The flywheel, specifically part 4934885, is an integral component within the engine system, serving multiple functions that contribute to the overall performance and efficiency of the engine.

Energy Storage and Smooth Operation

One of the primary roles of the flywheel is to store rotational energy. When the engine’s pistons move, they generate power that is transferred to the flywheel. This stored energy helps maintain the engine’s momentum between power strokes, ensuring a smoother and more consistent operation. The flywheel’s mass and design allow it to effectively store and release this energy, which is essential for the engine’s stability and performance 9.

Clutch Engagement

The flywheel also plays a significant role in the clutch system. It is directly connected to the pressure plate, which is part of the clutch assembly. When the clutch pedal is depressed, the pressure plate disengages from the flywheel, allowing the driver to change gears without interrupting the engine’s operation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring power from the engine to the transmission and ultimately to the wheels. This seamless engagement and disengagement are vital for smooth gear changes and efficient power transmission 10.

Vibration Dampening

Another important function of the flywheel is vibration dampening. The engine produces vibrations during operation, which can be transferred to other components if not properly managed. The flywheel’s design helps absorb and dampen these vibrations, reducing the stress on the engine and transmission components. This not only enhances the longevity of the engine system but also contributes to a more comfortable driving experience 11.

Starter Motor Interaction

During engine start-up, the flywheel interacts with the starter motor. The starter motor engages a ring gear attached to the flywheel to crank the engine. This interaction is essential for initiating the engine’s operation. The flywheel’s robust construction ensures it can withstand the repeated engagements with the starter motor without sustaining damage 12.

Balancing the Engine

The flywheel also contributes to the engine’s balance. Its weight and placement help counteract the forces generated by the reciprocating motion of the pistons. This balancing effect is particularly important in inline engines, where the flywheel helps maintain the engine’s stability and reduces the likelihood of excessive vibration 13.

Conclusion

In summary, the 4934885 flywheel is a multifaceted component that enhances the engine’s performance, ensures smooth operation, and contributes to the overall efficiency and reliability of the engine system. Its design and features make it a critical part of commercial truck engines, providing benefits such as improved performance, enhanced fuel efficiency, and increased durability.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Cummins Inc. (n.d.). Service Manual (5659745).

↩ -

Cummins Inc. (n.d.). Service Manual (5659745).

↩ -

Cummins Inc. (n.d.). Service Manual (5659745).

↩ -

Cummins Inc. (n.d.). Service Manual (5659745).

↩ -

Cummins Inc. (n.d.). Service Manual (5659745).

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Cummins Inc. (n.d.). Service Manual (5659745).

↩ -

Cummins Inc. (n.d.). Service Manual (5659745).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.