This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4946105 Air Transfer Pipe, manufactured by Cummins, is a vital component designed for the efficient transfer of air within heavy-duty truck systems. Cummins, a renowned entity in the automotive industry, is celebrated for its high-quality diesel engines and components. This specific air transfer pipe is crucial for the operation of heavy-duty trucks, ensuring that air-dependent systems function correctly.

Basic Concepts of Air Transfer Pipes

An Air Transfer Pipe serves as a conduit for the movement of air between various components within a truck’s air system. Its primary function is to maintain a consistent and efficient airflow, which is essential for the operation of systems such as the air brake system, suspension systems, and other air-actuated components. The efficiency of these systems is contingent upon the proper functioning of the air transfer pipes, making them a critical element in the overall performance and safety of the vehicle 1.

Purpose of the 4946105 Air Transfer Pipe

The 4946105 Air Transfer Pipe plays a pivotal role in the operation of a truck by ensuring the smooth transfer of air to various air-dependent systems. It is particularly significant in the air brake system, where it helps maintain the necessary air pressure for safe and effective braking. Additionally, it supports other systems that rely on air pressure, contributing to the truck’s overall operational efficiency 2.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity even under demanding conditions. The design of the pipe includes features that facilitate easy installation and maintenance, as well as elements that ensure a secure fit within the truck’s air system. These attributes contribute to the pipe’s reliability and efficiency in transferring air 3.

Benefits

The benefits of the 4946105 Air Transfer Pipe include improved air system efficiency, enhanced durability, and increased reliability. By ensuring a consistent and efficient airflow, it contributes to the optimal performance of air-dependent systems. Its durable construction and reliable operation are essential for the safety and efficiency of heavy-duty trucks, making it a valuable component for fleet operators and truck manufacturers alike 4.

Installation Considerations

When installing the 4946105 Air Transfer Pipe, it is important to consider compatibility with the specific truck model and air system. Proper installation involves ensuring a secure and effective fit, which may require following manufacturer guidelines and using appropriate tools and techniques. Attention to detail during installation can prevent issues such as leaks or blockages, ensuring the pipe functions as intended.

Troubleshooting Common Issues

Common problems associated with Air Transfer Pipes include leaks and blockages, which can affect the efficiency of air-dependent systems. Troubleshooting these issues involves inspecting the pipe for signs of damage or wear, checking connections for tightness, and ensuring there are no obstructions in the airflow. Addressing these problems promptly can help maintain the performance and safety of the truck.

Maintenance Tips

Regular maintenance of the 4946105 Air Transfer Pipe is important for ensuring its longevity and optimal performance. Maintenance routines should include periodic inspections for signs of wear or damage, cleaning to remove any debris that may obstruct airflow, and checking connections to ensure they remain secure. Following these maintenance tips can help prevent issues and ensure the pipe continues to function efficiently.

Cummins Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. Its expertise in diesel engines and components, including the 4946105 Air Transfer Pipe, underscores its dedication to providing reliable and high-performance solutions for the heavy-duty truck market.

Cummins Engine Compatibility with Air Transfer Pipe Part 4946105

The Cummins Air Transfer Pipe part number 4946105 is designed to fit a variety of Cummins engines, ensuring efficient airflow and optimal engine performance. This part is compatible with the following engine models:

6C8.3 and L8.9 CM2670 L134C

The 6C8.3 and L8.9 CM2670 L134C engines benefit from the Air Transfer Pipe part 4946105 by maintaining a consistent air supply to the engine’s combustion chambers. This part is crucial for ensuring that the engine operates smoothly and efficiently, particularly in demanding applications.

QSC8.3 CM2880 C102 and QSL9.3 CM2880 L113

Similarly, the QSC8.3 CM2880 C102 and QSL9.3 CM2880 L113 engines are designed to work seamlessly with the Air Transfer Pipe part 4946105. This component helps in managing the air intake process, which is vital for the engines’ performance and longevity. The design of this part ensures that it fits perfectly with these engines, providing a reliable and durable solution for air transfer needs.

By using the Air Transfer Pipe part 4946105, these engines can achieve better air management, leading to improved efficiency and reduced wear and tear over time. This part is a critical component in the overall maintenance and performance of these Cummins engines.

Role of Part 4946105 Air Transfer Pipe in Engine Systems

The 4946105 Air Transfer Pipe is an integral component in various engine systems, facilitating the efficient transfer of air between different parts of the engine. This pipe ensures that the air required for combustion reaches the engine’s cylinders in a controlled and regulated manner.

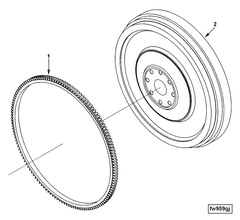

In conjunction with the Flywheel, the Air Transfer Pipe plays a significant role in maintaining engine stability and performance. The Flywheel, which stores rotational energy and smooths out the power delivery from the engine’s cylinders, relies on a consistent supply of air to ensure optimal combustion. The Air Transfer Pipe delivers this air efficiently, contributing to the overall balance and efficiency of the engine.

Additionally, the Air Transfer Pipe interacts with other components such as the Intake Manifold and Throttle Body. The Intake Manifold distributes air into the engine’s cylinders, and the Throttle Body controls the amount of air entering the engine. The Air Transfer Pipe ensures that air flows seamlessly from the air filter to these components, enhancing the engine’s responsiveness and power output.

Furthermore, the pipe works in tandem with the Mass Air Flow (MAF) Sensor to measure the amount of air entering the engine. Accurate air measurement is essential for the Engine Control Unit (ECU) to calculate the correct fuel-to-air ratio, ensuring efficient combustion and reducing emissions.

In summary, the 4946105 Air Transfer Pipe is a key element in the air induction system, supporting the function of multiple engine components and contributing to the engine’s overall performance and efficiency.

Conclusion

The 4946105 Air Transfer Pipe by Cummins is a critical component in the operation of heavy-duty trucks, ensuring efficient air transfer within the vehicle’s systems. Its durable construction, reliable performance, and compatibility with various Cummins engines make it an essential part for maintaining the safety and efficiency of these vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.