This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

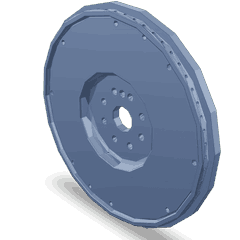

The Cummins 5318535 Flywheel is a component designed to enhance the operation of commercial trucks. Its purpose is to store rotational energy and smooth out engine operation, contributing to the overall efficiency and performance of the vehicle. Understanding its function and significance is vital for maintaining and optimizing truck performance.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing energy during acceleration and releasing it during deceleration. This mechanism smooths out engine operation, reducing vibrations and ensuring a steady power delivery. Flywheels play a role in stabilizing the engine’s rotational speed, which is crucial for efficient operation and longevity of the engine components 1.

Purpose of the Cummins 5318535 Flywheel

The Cummins 5318535 Flywheel is specifically engineered to enhance the operation of trucks by storing rotational energy and smoothing out engine operation. It contributes to engine performance by ensuring a consistent rotational speed, which aids in efficient fuel combustion and reduces wear on engine components. Additionally, it plays a role in the overall drivetrain functionality by providing a stable platform for power transmission from the engine to the transmission system.

Key Features

The Cummins 5318535 Flywheel is characterized by its robust design and high-quality materials, which include a durable cast iron construction. This design ensures it can withstand the high stresses and loads encountered in commercial truck applications. Unique characteristics of this flywheel include its precision machining and balanced design, which contribute to its smooth operation and longevity. The engineering considerations that went into its development focused on maximizing performance, durability, and efficiency.

Benefits

The Cummins 5318535 Flywheel offers several benefits, including improved engine performance, enhanced fuel efficiency, and increased durability. By storing rotational energy and smoothing out engine operation, it contributes to a more consistent power delivery, which can lead to better overall engine performance. Additionally, its design helps to reduce fuel consumption by ensuring efficient energy transfer within the engine system. The durability of the flywheel means it can withstand the rigors of commercial truck use, providing long-term reliability for operators and fleet managers.

Troubleshooting and Maintenance

Common issues related to the Cummins 5318535 Flywheel may include vibrations, unusual noises, or difficulty in starting the engine. These symptoms can be indicative of wear, imbalance, or other mechanical issues. Routine maintenance practices, such as regular inspections for wear and damage, ensuring proper alignment, and balancing the flywheel, are recommended to ensure optimal performance and longevity. Addressing issues promptly and performing routine maintenance can help prevent more significant problems down the line.

Installation Considerations

Proper installation of the Cummins 5318535 Flywheel is crucial for ensuring optimal performance and longevity. Specific requirements may include ensuring the flywheel is properly aligned with the engine and transmission, using the correct torque specifications for fastening, and verifying that all mating surfaces are clean and free of debris. Following best practices for installation helps to minimize the risk of issues such as misalignment, vibrations, or premature wear.

Compatibility and Applications

The Cummins 5318535 Flywheel is designed for use in various commercial truck models and engine configurations. It is commonly used in applications where reliable and efficient engine operation is critical. Understanding its compatibility with specific truck models and engine types is important for ensuring proper fit and function.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and powertrain solutions for commercial vehicles. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance components. Their flywheels, including the 5318535 model, are designed with precision engineering and durable materials to meet the demands of commercial truck applications.

Cummins Flywheel 5318535 Compatibility

The Cummins flywheel part number 5318535 is designed to fit a variety of Cummins engines, ensuring compatibility across different engine models. This flywheel is engineered to work seamlessly with the following engines:

- B5.9 CM2670 B166C

- D4.0 CM2620 D103B

- ISB3.9 CM2220 B107

- QSB3.9 CM2880 B138

- QSB5.9 CM2880 B139

For the B5.9 CM2670 B166C and D4.0 CM2620 D103B, the flywheel is tailored to ensure smooth operation and efficient power transfer. These engines, known for their reliability and performance, benefit from the precision engineering of the 5318535 flywheel.

Similarly, the ISB3.9 CM2220 B107 engine is designed to work optimally with this flywheel, providing a balance of power and durability. The flywheel’s design supports the engine’s performance characteristics, ensuring consistent and reliable operation.

The QSB3.9 CM2880 B138 and QSB5.9 CM2880 B139 engines also benefit from the 5318535 flywheel. These engines, known for their robust construction and efficiency, are paired with a flywheel that enhances their operational capabilities. The flywheel’s design is critical in maintaining the engine’s performance and longevity.

In summary, the Cummins flywheel part number 5318535 is a versatile component that ensures compatibility and optimal performance across a range of Cummins engines, including the B5.9, D4.0, ISB3.9, QSB3.9, and QSB5.9 models.

Role of Part 5318535 Flywheel in Engine Systems

The flywheel, specifically part 5318535, is an integral component in the operation of engine systems, serving multiple functions that contribute to the overall efficiency and performance of the engine.

Energy Storage and Smooth Operation

The primary role of the flywheel is to store rotational energy. When the engine’s pistons move, they generate power strokes that cause the crankshaft to rotate. The flywheel absorbs and stores this rotational energy, smoothing out the power delivery between these strokes. This results in a more consistent and stable engine operation, reducing vibrations and ensuring a smoother ride 2.

Clutch Engagement

In manual transmission vehicles, the flywheel plays a key role in the clutch system. When the clutch pedal is depressed, the pressure plate is disengaged from the flywheel, allowing the driver to change gears without interrupting the engine’s operation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission and ultimately to the wheels.

Starter Motor Assistance

During engine start-up, the flywheel assists the starter motor. The starter motor engages with a ring gear attached to the flywheel, spinning it to initiate engine cranking. This action helps to start the engine by bringing the pistons to the necessary speed for combustion to occur.

Balancing the Engine

The flywheel also contributes to the engine’s balance. Its mass helps to counteract the reciprocating motion of the pistons and the rotating motion of the crankshaft. This balancing act minimizes vibrations and wear on engine components, prolonging the engine’s lifespan.

Flywheel Housing and Dual-Mass Flywheels

In some engine systems, the flywheel is part of a dual-mass flywheel (DMF) setup. The DMF consists of two masses connected by a series of springs, which further reduces vibrations and provides a smoother driving experience. The primary mass is connected to the crankshaft, while the secondary mass engages with the clutch. This setup enhances the flywheel’s role in smoothing engine operation and reducing wear on the drivetrain.

Integration with Other Components

The flywheel works in conjunction with several other engine components to ensure optimal performance. It interacts with the crankshaft, clutch system, starter motor, and transmission, forming a cohesive unit that enhances the engine’s efficiency and reliability.

Understanding the flywheel’s role in these systems allows engineers and mechanics to appreciate its significance in maintaining engine performance and durability.

Conclusion

The Cummins 5318535 Flywheel is a critical component in the operation of commercial trucks, designed to store rotational energy and smooth out engine operation. Its robust design, high-quality materials, and precise engineering contribute to improved engine performance, enhanced fuel efficiency, and increased durability. Proper installation, routine maintenance, and understanding its compatibility with various Cummins engines are essential for ensuring optimal performance and longevity. The flywheel’s role in energy storage, clutch engagement, starter motor assistance, engine balancing, and integration with other components underscores its significance in maintaining engine performance and durability.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.