This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

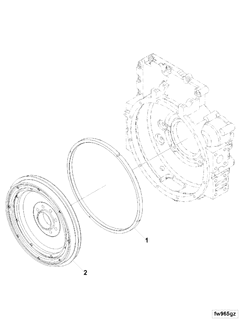

The Cummins 5348560 Flywheel Assembly is a critical component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by contributing to the smooth running of the engine and aiding in the starting process. Understanding its function and importance can help in maintaining and optimizing the performance of truck engines.

Basic Concepts of Flywheel Assemblies

A flywheel assembly is a mechanical device that operates within an engine system to store rotational energy. Its primary functions include stabilizing the engine’s rotational speed by counteracting fluctuations caused by the combustion process in each cylinder. This is achieved through the principle of inertia, where the flywheel resists changes in its rotational speed, thereby smoothing out the power delivery. Additionally, the flywheel plays a role in the engine’s starting mechanism by engaging with the starter motor to initiate engine rotation 1.

Purpose of the 5348560 Flywheel Assembly

The Cummins 5348560 Flywheel Assembly is integral to the operation of a truck’s engine. It functions by smoothing the engine’s operation, which is particularly important in diesel engines where combustion occurs in a more abrupt manner compared to gasoline engines. This smoothing effect reduces vibrations and ensures a more consistent power output. Furthermore, the flywheel assists in the starting process by providing the necessary inertia to turn the engine over, facilitating easier starts, especially in cold conditions or when the engine is under load 2.

Key Features

The Cummins 5348560 Flywheel Assembly is characterized by its robust design and the use of high-quality materials, which contribute to its performance and durability. It is engineered to withstand the high torque and stress levels typical of commercial truck engines. The assembly may include features such as a balanced weight distribution to minimize vibrations and a precision-machined surface for optimal engagement with the clutch. These attributes enhance the flywheel’s ability to perform reliably under demanding conditions 3.

Benefits of Using the 5348560 Flywheel Assembly

Incorporating the Cummins 5348560 Flywheel Assembly into truck engines offers several advantages. It contributes to improved engine performance by ensuring a smoother operation and more efficient power transmission. The assembly’s design and materials also enhance the engine’s reliability and efficiency, leading to potentially lower maintenance costs and extended engine life. Additionally, the flywheel’s role in the starting process can result in easier engine starts, which is beneficial for both the engine and the operator.

Installation Process

Proper installation of the Cummins 5348560 Flywheel Assembly involves several steps to ensure it functions correctly within the engine system. This process includes preparing the engine by removing the old flywheel, cleaning the mating surfaces, and inspecting the flywheel housing for any damage. The new flywheel is then aligned and secured in place, ensuring it is properly seated and all fasteners are tightened to the manufacturer’s specifications. Tools required may include a flywheel alignment tool, torque wrench, and possibly a flywheel removal tool, depending on the specific engine model.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 5348560 Flywheel Assembly is key to ensuring its longevity and optimal performance. This includes inspecting the flywheel for signs of wear or damage during routine engine maintenance checks. Common issues may include uneven wear on the flywheel surface, which can affect clutch engagement, or cracks that compromise its structural integrity. Diagnostic tips involve listening for unusual noises during engine operation or difficulty in starting the engine, which may indicate flywheel problems. Troubleshooting procedures should follow manufacturer guidelines to address any identified issues promptly.

Compatibility and Applications

The Cummins 5348560 Flywheel Assembly is designed for specific types of engines and truck models. Its applications span across various commercial truck segments, where it is utilized for its reliability and performance benefits. The assembly is engineered to meet the demanding requirements of these applications, ensuring compatibility with the engine’s design and operational parameters.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and engine manufacturing industry. The company’s product range includes engines for on-highway and off-highway applications, as well as power generation and marine solutions, serving a diverse array of industries worldwide.

Cummins Flywheel Assembly Part 5348560 Compatibility

The Cummins Flywheel Assembly part number 5348560 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is engineered to work with the B4.5 CM2350 B129B and B6.7 CM2350 B135B engines, providing a critical component in the engine’s operation.

B4.5 CM2350 B129B Engine

For the B4.5 CM2350 B129B engine, the flywheel assembly plays a pivotal role in maintaining the engine’s rotational momentum and ensuring smooth power delivery. This engine variant is known for its efficiency and reliability, and the flywheel assembly is a key part of its design, contributing to the engine’s overall performance.

B6.7 CM2350 B135B Engine

Similarly, the B6.7 CM2350 B135B engine benefits from the use of the Cummins Flywheel Assembly part number 5348560. This engine is recognized for its robust power output and durability, and the flywheel assembly is integral to its operation. It helps in the synchronization of the engine’s rotational movements, ensuring that the engine runs smoothly and efficiently.

Both engine models rely on the flywheel assembly to maintain the necessary balance and rotational inertia, which is crucial for the engine’s performance and longevity. The compatibility of the part with these engines ensures that users can maintain and repair their engines with confidence, knowing that the flywheel assembly is a reliable and essential component.

Role of Part 5348560 Flywheel Assembly in Engine Systems

The flywheel assembly, specifically part 5348560, is an integral component in the operation of an engine system. It is designed to work in harmony with several key components to ensure smooth and efficient engine performance.

Interaction with the Crankshaft

The flywheel assembly interfaces directly with the crankshaft. As the engine’s pistons move up and down, they impart rotational force to the crankshaft. The flywheel, attached to the crankshaft, stores this rotational energy and helps maintain consistent engine speed by smoothing out the power pulses delivered by the combustion process.

Relationship with the Clutch System

In manual transmission vehicles, the flywheel assembly is a critical part of the clutch system. When the clutch pedal is depressed, the pressure plate disengages from the flywheel, allowing the driver to change gears without interrupting the engine’s operation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission.

Contribution to the Starter Motor

During engine start-up, the flywheel assembly plays a vital role in engaging with the starter motor. The starter motor’s gear, known as the Bendix drive, meshes with the flywheel’s ring gear to crank the engine. Once the engine starts, the flywheel continues to rotate, helping to build momentum and stabilize the engine’s rotational speed.

Balance and Vibration Reduction

The flywheel’s mass and design contribute to balancing the engine. By counteracting the reciprocating motion of the pistons, it reduces vibrations and ensures a smoother operation. This balance is essential for the longevity and reliability of the engine components.

Energy Storage and Release

One of the flywheel assembly’s primary functions is to store kinetic energy. As the engine runs, the flywheel accumulates energy during the power stroke and releases it during the other strokes (intake, compression, and exhaust). This energy exchange helps maintain a consistent rotational speed, which is essential for stable engine performance.

Conclusion

In summary, the Cummins 5348560 Flywheel Assembly is a multifaceted component that interacts with the crankshaft, clutch system, starter motor, and plays a significant role in balancing the engine and managing energy storage and release. Its proper function is essential for the overall efficiency and performance of the engine system.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.