This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

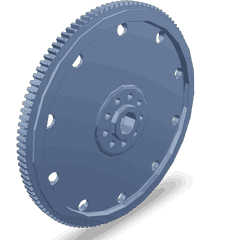

The Cummins 5593390 Flywheel is a critical component designed for use in commercial trucks, essential for the efficient operation of these vehicles. This part stores rotational energy and contributes to the smooth delivery of engine power, which is vital for the performance and reliability of heavy-duty trucks.

Basic Concepts of a Flywheel

A flywheel is a mechanical device designed to efficiently store rotational energy. It resists changes in rotational speed due to its mass, providing a stabilizing effect on the engine’s operation. Within an engine system, the flywheel smooths out the power delivery from the engine’s cylinders and assists in the operation of the starter motor during engine cranking 1.

Purpose of the Cummins 5593390 Flywheel

The Cummins 5593390 Flywheel is integral to the operation of a truck’s engine. It stores rotational energy generated by the engine and releases it to maintain consistent power delivery between the firing of the engine’s cylinders. This function helps to smooth out the power pulses, leading to a more stable and efficient engine operation. Additionally, the flywheel plays a role in the engagement of the clutch, allowing for smooth gear changes 2.

Key Features

The Cummins 5593390 Flywheel is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. It features a balanced mass that ensures smooth operation and reduces vibrations. The flywheel’s design also incorporates specific characteristics to enhance its efficiency in storing and transferring rotational energy 3.

Benefits of Using the Cummins 5593390 Flywheel

Utilizing the Cummins 5593390 Flywheel in a truck’s engine system offers several advantages. These include improved engine efficiency due to the flywheel’s ability to smooth out power delivery, enhanced durability that contributes to the longevity of the engine, and potential increases in vehicle performance. The flywheel’s design and materials also contribute to reduced wear on other engine components, leading to overall improved engine health.

Installation Considerations

Proper installation of the Cummins 5593390 Flywheel is crucial for ensuring its effective operation and the overall performance of the engine. Guidelines for installation include ensuring the flywheel is correctly aligned with the engine and transmission, using the appropriate tools for tightening bolts to the specified torque, and verifying that all mating surfaces are clean and free of debris. Special attention should be given to the balance of the flywheel to prevent vibrations.

Maintenance and Troubleshooting

Maintaining the Cummins 5593390 Flywheel involves regular inspections for signs of wear or damage, ensuring that it remains properly aligned and balanced. Common issues that may arise include uneven wear on the flywheel surface, which can affect engine performance, and problems with the clutch engagement. Troubleshooting steps may involve checking the alignment and balance of the flywheel, inspecting the clutch for wear, and ensuring that all connections are secure and free of corrosion.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive experience and expertise in engine technology are reflected in the design and performance of components like the Cummins 5593390 Flywheel.

Role of Part 5593390 Flywheel in Engine Systems

The flywheel, specifically part 5593390, is integral to the operation of the engine system. It is mounted on the crankshaft and serves multiple functions that contribute to the overall performance and efficiency of the engine.

Energy Storage and Smooth Operation

One of the primary roles of the flywheel is to store rotational energy. As the engine cycles through its power strokes, the flywheel accumulates energy, which it then releases during the non-power strokes (intake, compression, and exhaust). This energy transfer helps maintain a consistent rotational speed, ensuring smooth engine operation even when the load varies.

Clutch Engagement

In manual transmission vehicles, the flywheel plays a key role in the clutch system. When the clutch pedal is depressed, the pressure plate is disengaged from the flywheel, allowing the driver to change gears without interrupting the engine’s rotation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission and ultimately to the wheels.

Vibration Dampening

The flywheel also acts as a vibration dampener. By virtue of its mass and rotational inertia, it helps to absorb and smooth out the vibrations generated by the engine’s reciprocating components. This not only enhances driver comfort but also reduces wear on other engine components.

Starter Motor Interaction

During engine start-up, the flywheel engages with the starter motor’s pinion gear. The starter motor rotates the flywheel, which in turn rotates the crankshaft, initiating the engine’s combustion cycle. The flywheel’s substantial mass ensures that the engine can be started reliably, even under cold conditions.

Balancing the Engine

The flywheel contributes to the engine’s overall balance. Its mass helps counteract the imbalances created by the reciprocating motion of the pistons and the rotating motion of the crankshaft. This balance is essential for reducing mechanical stress and enhancing the longevity of engine components.

Conclusion

In summary, the Cummins 5593390 Flywheel is a multifaceted component that ensures the engine operates smoothly, efficiently, and reliably. Its interactions with the crankshaft, clutch system, starter motor, and other engine components underscore its importance in the engine’s functionality.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.