4960126

Flywheel Housing Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Flywheel Housing Seal, identified by Part #4960126, is a component manufactured by Cummins, a prominent entity in the heavy-duty truck industry. This seal is integral to the operation of heavy-duty trucks, ensuring the efficient and reliable performance of the engine system. Cummins, known for its high-quality and durable parts, provides this seal as part of its extensive range of engine components designed to meet the demanding requirements of heavy-duty applications 1.

Function and Operation

The Flywheel Housing Seal plays a role in the truck’s engine system by maintaining the integrity of the flywheel housing. It prevents oil leaks and keeps contaminants from entering the housing. This seal ensures that the flywheel operates in a clean and lubricated environment, which is vital for the smooth operation of the engine. By effectively sealing the flywheel housing, it contributes to the overall efficiency and longevity of the engine 2.

Key Features

The design and material characteristics of the Flywheel Housing Seal are tailored to withstand the harsh conditions within a heavy-duty truck engine. It is constructed from durable materials that offer resistance to high temperatures and pressures. The seal is designed for a precision fit, ensuring it effectively blocks any pathways for oil leakage or contaminant ingress. These features make it a reliable component in the engine system 3.

Benefits

Utilizing a high-quality Flywheel Housing Seal, such as the one offered by Cummins, can lead to several advantages. These include improved engine performance due to consistent lubrication and protection from contaminants. The seal’s durability and precision fit contribute to increased engine reliability, reducing the likelihood of unexpected failures. Additionally, a well-maintained seal can lead to reduced maintenance costs over the lifespan of the engine 4.

Installation Process

Proper installation of the Flywheel Housing Seal is crucial for its effective operation. The process involves carefully cleaning the sealing surface to remove any debris or old sealant. The new seal should be positioned correctly within the flywheel housing, ensuring it is seated properly without damage. It is important to follow manufacturer guidelines to avoid common pitfalls such as improper seating or damage to the seal during installation 5.

Maintenance and Troubleshooting

Regular inspection and maintenance of the Flywheel Housing Seal are recommended to ensure its continued effectiveness. This includes checking for signs of wear, leaks, or damage during routine engine maintenance. Troubleshooting common issues such as leaks may involve inspecting the seal for proper seating or signs of degradation. Addressing these issues promptly can prevent more significant problems down the line 6.

Common Failure Modes

Flywheel Housing Seals can fail due to various reasons, including wear from continuous operation, improper installation, or exposure to extreme conditions. Understanding these failure modes can help in identifying the root cause of seal failure and taking corrective action. Regular maintenance and proper installation practices can mitigate these risks 7.

Replacement Procedures

When a Flywheel Housing Seal needs replacement, it is important to follow a systematic approach. This includes safely removing the old seal, cleaning the sealing surface, and installing the new seal according to manufacturer specifications. Using the correct tools and following procedures ensures a proper fit and effective sealing, contributing to the engine’s reliable operation 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the heavy-duty truck industry, Cummins is committed to delivering high-quality, reliable components that meet the needs of its customers. The company’s extensive product range and focus on innovation and customer satisfaction have established it as a trusted name in the industry 9.

Cummins Flywheel Housing Seal (Part 4960126) Compatibility

The Cummins Flywheel Housing Seal, identified by part number 4960126, is a critical component designed to ensure the integrity of the flywheel housing system in various engine models. This seal is engineered to prevent oil leaks and maintain the necessary pressure within the engine’s flywheel housing, contributing to the overall efficiency and longevity of the engine.

Compatible Engines

The flywheel housing seal is compatible with several Cummins engine models, including:

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- ISZ13 CM2150 Z105

- QSX11.9 CM2250 ECF

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

- Z13 Z108G

Grouping of Compatible Engines

For ease of reference, the compatible engines can be grouped based on their model series:

-

ISX Series:

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

-

ISZ Series:

- ISZ13 CM2150 Z105

-

QSX Series:

- QSX11.9 CM2250 ECF

-

QSZ Series:

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

-

Z13 Series:

- Z13 Z108G

Each of these engines benefits from the use of the Cummins Flywheel Housing Seal, ensuring that the flywheel housing remains sealed and operational, thereby maintaining the engine’s performance and reliability.

Role of Part 4960126 Flywheel Housing Seal in Engine Systems

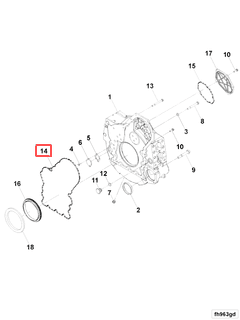

The 4960126 Flywheel Housing Seal is an essential component in the assembly and maintenance of engine systems, specifically interacting with the housing, flywheel, lower engine gasket kit, and overhaul kit.

Interaction with Housing and Flywheel

The flywheel housing seal is positioned between the housing and the flywheel. Its primary function is to create a secure seal, preventing any leakage of fluids or gases that could compromise engine performance. This seal ensures that the flywheel operates within a contained environment, maintaining the integrity of the system.

Integration with Lower Engine Gasket Kit

When installing or replacing the lower engine gasket kit, the flywheel housing seal plays a supportive role. The seal complements the gaskets by providing an additional layer of security against leaks. This is particularly important in the lower section of the engine where various fluids and pressures are present.

Contribution to Overhaul Kit

In the context of an overhaul kit, the flywheel housing seal is often included to ensure that all critical sealing points are addressed during a comprehensive engine rebuild. The seal is replaced to guarantee that the engine starts with a clean slate, free from any previous wear or damage that could affect performance.

Overall Functionality

The flywheel housing seal, while a small component, significantly contributes to the overall functionality and reliability of the engine system. It works in conjunction with other components to maintain a sealed environment, ensuring optimal engine performance and longevity.

Conclusion

The Flywheel Housing Seal, part number 4960126, is a vital component in the maintenance and operation of heavy-duty truck engines. Its role in preventing oil leaks, maintaining system integrity, and contributing to engine efficiency and longevity cannot be overstated. Proper installation, regular maintenance, and understanding of common failure modes are crucial for maximizing the benefits of this Cummins part. As part of Cummins’ commitment to quality and reliability, the 4960126 Flywheel Housing Seal stands as a testament to the company’s dedication to providing durable and effective engine components.

-

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383850.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383850.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383850.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383850.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383850.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383850.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383850.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.