This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

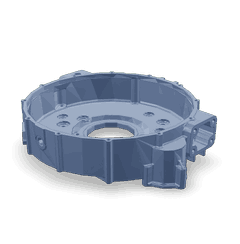

The Flywheel Housing 2831369 by Cummins is a vital component designed for commercial trucks, contributing significantly to the engine’s operation. This housing is integral to the truck’s performance, ensuring efficient power transmission and supporting critical engine functions.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, a heavy rotating disc that stores rotational energy. It facilitates the smooth operation of the engine by interacting with the clutch and transmission. The housing ensures that the flywheel operates within a controlled environment, minimizing wear and enhancing the efficiency of power transfer from the engine to the transmission 1.

Purpose of the 2831369 Flywheel Housing

The 2831369 Flywheel Housing is designed to support the flywheel, which is essential for maintaining engine momentum and facilitating smooth gear transitions. By providing a secure enclosure, it helps in reducing noise, containing vibrations, and protecting the flywheel from external elements. This housing plays a role in the overall efficiency and reliability of the truck’s drivetrain system.

Key Features

This part is constructed from high-quality materials, ensuring durability and resistance to wear. Its design includes precision-machined surfaces to ensure a perfect fit with the flywheel and other components. Additionally, it features robust mounting points to withstand the stresses of heavy-duty operations. Unique attributes such as enhanced sealing mechanisms contribute to its performance by preventing leaks and maintaining optimal operating conditions.

Benefits

The 2831369 Flywheel Housing offers several benefits, including improved engine performance through efficient power transmission. Its durable construction contributes to the longevity of the truck’s drivetrain, potentially leading to reduced maintenance needs. Furthermore, by ensuring smooth operation of the flywheel and clutch, it may contribute to better fuel efficiency and overall truck performance.

Installation Considerations

Proper installation of the 2831369 Flywheel Housing is crucial for its effective operation. It requires careful alignment with the flywheel and clutch components. Tools such as torque wrenches are necessary to ensure secure fastening. Following manufacturer guidelines for installation procedures will help in achieving a secure and effective fit, ensuring the housing functions as intended within the engine system.

Troubleshooting Common Issues

Common issues with flywheel housings include leaks, excessive wear, and noise. Diagnostic steps may involve inspecting seals for damage, checking for signs of wear on mating surfaces, and listening for unusual sounds during operation. Solutions might range from replacing worn seals to addressing misalignments or, in severe cases, replacing the housing to restore optimal function.

Maintenance Tips

Routine maintenance of the 2831369 Flywheel Housing involves regular inspections for signs of wear or damage, cleaning to remove any debris that could affect performance, and checking seals for integrity. Adhering to recommended inspection intervals and performing maintenance tasks as needed will help prolong the lifespan of the housing and ensure continued reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the commercial truck industry. The 2831369 Flywheel Housing is a testament to Cummins’ commitment to providing durable, high-performance components for the demanding environments of commercial trucking.

Compatibility with Cummins Engines

This part is compatible with several Cummins engine models, including the ISBE CM800 series, which are designed for heavy-duty applications. This compatibility ensures that the housing provides the necessary support and protection for the flywheel, contributing to the engine’s overall durability and performance. It is also compatible with other Cummins engines within similar heavy-duty applications, ensuring that the housing aligns perfectly with the engine’s components and maintains the integrity of the engine’s operation.

Role of Part 2831369 Flywheel Housing in Engine Systems

The flywheel housing, identified by part number 2831369, is an integral component in the assembly and operation of engine systems. It serves as the protective enclosure for the flywheel, which is a heavy, rotating disk that stores rotational energy and smooths out the power delivery from the engine’s cylinders.

Integration with Key Components

-

Flywheel: The primary interaction is with the flywheel itself. The housing encases the flywheel, providing a secure environment that shields it from external elements and ensures it operates within specified tolerances. This enclosure helps maintain the flywheel’s alignment and balance, which are essential for consistent engine performance.

-

Clutch Assembly: In manual transmission vehicles, the flywheel housing interacts closely with the clutch assembly. The housing must align perfectly with the clutch pressure plate and the clutch disc to ensure smooth engagement and disengagement of the clutch. Proper alignment is vital for the efficient transfer of power from the engine to the transmission.

-

Torque Converter (Automatic Transmissions): In automatic transmission systems, the flywheel housing interfaces with the torque converter. The housing must be designed to accommodate the torque converter’s components, allowing for the fluid coupling that transmits engine power to the transmission. This interaction ensures that the rotational energy is efficiently converted into hydraulic force.

-

Engine Block: The flywheel housing is bolted directly to the engine block, typically at the rear of the engine. This connection is critical for maintaining the structural integrity of the engine assembly. The housing must be robust enough to withstand the high torque and vibrations generated by the engine.

-

Starter Motor: The housing also provides a mounting point for the starter motor. The starter motor engages with the flywheel to crank the engine during startup. The precise fit between the flywheel housing and the starter motor ensures reliable engine starts and reduces the risk of mechanical failure.

-

Dual Mass Flywheel (DMF) Systems: In vehicles equipped with a DMF, the housing must be compatible with the additional components of the DMF system. This includes the primary and secondary masses, the sprag clutch, and the dampening springs. The housing must allow for the necessary movement and vibration dampening provided by the DMF.

-

Flywheel Bolts and Fasteners: The housing is secured to the engine block using flywheel bolts or fasteners. These components must be torqued to the manufacturer’s specifications to ensure a secure fit. The housing design must accommodate these fasteners, providing the necessary threading and spacing.

-

Flywheel Inspection Cover: Some flywheel housings include an inspection cover, allowing for easy access to the flywheel and clutch components without fully disassembling the housing. This feature is particularly useful for maintenance and diagnostic purposes.

Conclusion

The 2831369 Flywheel Housing by Cummins is a critical component in the operation of commercial truck engines. Its role in protecting the flywheel, ensuring efficient power transmission, and integrating with key engine components highlights its importance in maintaining engine performance and reliability. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part and ensure the longevity of the engine system.

-

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.