This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

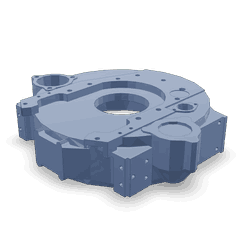

The Flywheel Housing 3005557, manufactured by Cummins, is a component designed for heavy-duty truck engines. Cummins, a well-established name in the commercial truck industry, produces a range of high-quality engine parts, including the Flywheel Housing 3005557. This part is significant in the operation of heavy-duty truck engines, contributing to their efficiency and reliability.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, a key component in the engine’s power transmission system. Its primary functions include safeguarding the flywheel from external elements, facilitating the connection between the engine and transmission, and contributing to the smooth operation of the clutch system. The flywheel housing integrates with other engine components such as the crankshaft, flywheel, and clutch, playing a vital role in the engine’s overall functionality 1.

Purpose of Flywheel Housing 3005557

The Flywheel Housing 3005557 serves a crucial role in the operation of a truck by enclosing and protecting the flywheel. It ensures the flywheel operates within a controlled environment, shielding it from debris and contaminants. This housing also plays a part in the interaction between the flywheel, clutch, and transmission, facilitating the transfer of power from the engine to the transmission system. Its design allows for efficient power transmission and contributes to the overall performance of the truck’s engine 2.

Key Features

The Flywheel Housing 3005557 is characterized by several distinctive features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates precise engineering specifications to ensure a perfect fit with the engine components. Additionally, it features robust mounting points and alignment provisions, contributing to its stability and reliability under heavy-duty conditions.

Benefits

The advantages provided by the Flywheel Housing 3005557 include improved engine efficiency, enhanced durability, and reliable performance under demanding conditions. Its high-quality construction and precise engineering contribute to the smooth operation of the engine, reducing the likelihood of mechanical failures. The protective enclosure ensures the flywheel remains in optimal condition, contributing to the overall efficiency and longevity of the engine.

Installation Process

Proper installation of the Flywheel Housing 3005557 is crucial for ensuring its effectiveness and longevity. The process involves several steps, including preparing the engine compartment, aligning the housing with the flywheel and transmission, securing it in place, and conducting final checks to ensure everything is correctly installed. Mechanics and engineers should follow best practices, such as using the correct tools and torque specifications, to ensure a successful installation.

Troubleshooting and Maintenance

Common issues associated with flywheel housings include misalignment, wear, and damage from external elements. Diagnostic tips for identifying these issues include checking for unusual noises, vibrations, or difficulty in shifting gears. Maintenance practices to ensure the longevity and optimal performance of the Flywheel Housing 3005557 include regular inspections, cleaning, and addressing any signs of wear or damage promptly. Proper maintenance contributes to the reliable operation of the engine and extends the lifespan of the flywheel housing.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable engine parts. The company’s product range includes a variety of engine components and systems designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted name in the industry.

Cummins Flywheel Housing Part 3005557 Compatibility

The Cummins flywheel housing part number 3005557 is designed to fit a range of engines, ensuring compatibility across various models. This part is crucial for maintaining the integrity and performance of the engine’s flywheel system.

N14 MECHANICAL

The N14 MECHANICAL engine is a robust and reliable option, often used in heavy-duty applications. The flywheel housing part 3005557 is engineered to seamlessly integrate with the N14 MECHANICAL, providing a secure fit that enhances the engine’s operational efficiency.

NH/NT 855

The NH/NT 855 engines are known for their versatility and durability, making them suitable for a variety of industrial and commercial applications. The flywheel housing part 3005557 is specifically designed to fit these engines, ensuring a precise alignment that supports optimal performance and longevity.

QSNT14 CM876 N102

The QSNT14 CM876 N102 engine is another variant that benefits from the compatibility of the flywheel housing part 3005557. This part is crafted to fit this engine model, ensuring that the flywheel system operates smoothly and efficiently, contributing to the overall reliability of the engine.

By ensuring compatibility with these engines, the flywheel housing part 3005557 from Cummins provides a reliable and efficient solution for maintaining the performance and longevity of the engine’s flywheel system.

Role of Part 3005557 Flywheel Housing in Engine Systems

The flywheel housing, identified by part number 3005557, is an integral component in the assembly and operation of engine systems. It serves as the protective enclosure for the flywheel, which is a heavy rotating disc that stores rotational energy and smooths out the delivery of power from a motor to the transmission.

When integrating the flywheel housing into an engine system, it interfaces directly with the engine block. This housing ensures that the flywheel is securely mounted and aligned with the crankshaft. The crankshaft, connected to the flywheel via the flywheel ring gear, transfers rotational force generated by the engine’s combustion process.

Additionally, the flywheel housing plays a role in the operation of the starter motor. The ring gear attached to the flywheel engages with the starter motor’s pinion gear during engine start-up, allowing the starter motor to turn the flywheel and initiate engine operation.

Moreover, the housing contributes to the structural integrity of the engine by providing a stable mounting point for the clutch assembly. In manual transmission vehicles, the pressure plate and clutch disc are mounted to the flywheel, and the flywheel housing supports this assembly, ensuring smooth and efficient power transfer from the engine to the transmission.

In summary, the flywheel housing (part 3005557) is essential for the proper function and integration of the flywheel, crankshaft, starter motor, and clutch assembly within the engine system. Its role in protecting and aligning these components is fundamental to the engine’s performance and durability.

Conclusion

The Flywheel Housing 3005557 is a critical component in the operation of heavy-duty truck engines, offering protection, efficient power transmission, and integration with key engine components. Its high-quality construction, precise engineering, and compatibility with various Cummins engines make it a reliable choice for maintaining engine performance and durability. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.