This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

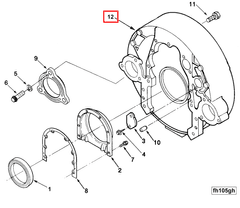

The Cummins 3036079 Flywheel Housing is a component designed for heavy-duty truck engines. It serves a pivotal role in the engine’s operation by providing a secure enclosure for the flywheel, which is integral to the engine’s balance and performance. This housing is engineered to withstand the rigorous demands of heavy-duty applications, ensuring reliable operation and efficiency.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective casing that encases the flywheel, a heavy rotating disc that stores rotational energy and smooths out the power delivery from the engine. The housing plays a role in the engine system by securing the flywheel in place, protecting it from external elements, and facilitating the transfer of rotational energy to the transmission. It interfaces with various engine components, including the crankshaft and clutch assembly, to ensure seamless operation 1.

Purpose of the Cummins 3036079 Flywheel Housing

The Cummins 3036079 Flywheel Housing is designed to support the flywheel within the engine assembly. Its role involves maintaining the flywheel’s position and alignment, which is vital for the engine’s balance and smooth operation. By providing a robust enclosure, it contributes to the overall stability and performance of the engine, especially under the demanding conditions typical of heavy-duty truck applications 2.

Key Features

The Cummins 3036079 Flywheel Housing is characterized by several key features that enhance its performance and durability. It is constructed from high-strength materials to resist wear and tear. The design incorporates precise engineering to ensure a perfect fit with the engine components, facilitating efficient energy transfer. Additionally, it features robust mounting points and seals to prevent leaks and ensure a secure enclosure for the flywheel 3.

Benefits

The Cummins 3036079 Flywheel Housing offers several benefits that contribute to engine efficiency and durability. Its high-strength material composition and precise design help to improve engine performance by ensuring smooth and reliable operation of the flywheel. The housing’s durability under heavy-duty conditions enhances the engine’s longevity, providing reliable performance over extended periods 4.

Installation Process

Installing the Cummins 3036079 Flywheel Housing involves several steps to ensure proper fit and function. Begin by preparing the engine bay, ensuring all mating surfaces are clean and free of debris. Align the housing with the engine’s mounting points, taking care to follow the manufacturer’s guidelines for torque specifications when securing it in place. Verify the alignment of the flywheel and ensure all seals are intact to prevent leaks. Finally, conduct a thorough inspection to confirm the housing is securely installed and functions as intended 5.

Common Issues and Troubleshooting

Common issues associated with the Cummins 3036079 Flywheel Housing may include leaks, cracks, or misalignment. To address these issues, begin by conducting a visual inspection for any signs of damage or wear. If leaks are detected, check the seals and gaskets for proper installation and condition. Cracks may require replacement of the housing, while misalignment issues can often be resolved by realigning the component or adjusting the mounting points. Always refer to the manufacturer’s troubleshooting guide for specific recommendations 6.

Maintenance Tips

To prolong the lifespan of the Cummins 3036079 Flywheel Housing, regular maintenance is recommended. This includes periodic inspections for signs of wear, damage, or leaks. Cleaning the housing and its surrounding areas can prevent the accumulation of debris that may lead to performance issues. Additionally, following the manufacturer’s recommended maintenance intervals for inspections and replacements can help ensure the housing remains in optimal condition 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the industry, Cummins is committed to producing high-quality components that meet the demanding requirements of heavy-duty applications. Their products are known for reliability, efficiency, and durability, making them a preferred choice for professionals in the automotive and heavy-duty truck sectors 8.

Role of Part 3036079 Flywheel Housing in Engine Systems

The flywheel housing, specifically part 3036079, is integral to the operation and efficiency of engine systems. This component encases the flywheel, which is a heavy rotating disc that stores rotational energy and smooths out the power delivery from the engine to the transmission.

Integration with Key Engine Components

-

Flywheel: The primary role of the flywheel housing is to securely hold the flywheel in place. The flywheel, in turn, is connected to the engine’s crankshaft via a series of bolts. This connection allows the flywheel to rotate in sync with the crankshaft, storing kinetic energy during the engine’s operation.

-

Crankshaft: The flywheel housing interfaces directly with the crankshaft through the flywheel. This setup ensures that the rotational energy produced by the engine is efficiently transferred to the transmission system.

-

Clutch Assembly: In manual transmission systems, the flywheel housing is closely associated with the clutch assembly. The pressure plate, which is part of the clutch, presses against the flywheel to engage or disengage the engine from the transmission. The housing provides the necessary structural support for this interaction.

-

Dual Mass Flywheel (DMF): In systems equipped with a DMF, the flywheel housing accommodates the additional components within the DMF, such as the secondary mass and the sprag clutch. This setup helps in reducing NVH (Noise, Vibration, and Harshness) levels, enhancing the overall driving experience.

-

Torque Converter (Automatic Transmissions): In automatic transmission systems, the flywheel housing may house the flexplate, which serves a similar energy-storing function as the flywheel. The torque converter, which replaces the clutch in automatic transmissions, connects to the flexplate to transmit engine power to the transmission.

-

Engine Mounts: The flywheel housing is also connected to the engine mounts, which secure the engine to the vehicle’s chassis. This connection helps in absorbing vibrations and ensuring stable engine operation.

-

Starter Motor: The flywheel housing provides a mounting point for the starter motor. The starter motor engages with the flywheel’s ring gear to crank the engine during startup, initiating the combustion process.

In summary, part 3036079 flywheel housing plays a significant role in maintaining the structural integrity and functional efficiency of the engine system. Its interactions with various components ensure smooth power transmission, effective energy storage, and stable engine operation 9.

Conclusion

The Cummins 3036079 Flywheel Housing is a critical component in heavy-duty truck engines, ensuring the flywheel’s secure enclosure and alignment. Its robust design and integration with key engine components contribute to the engine’s balance, performance, and durability. Regular maintenance and proper installation are essential to maximize its benefits and ensure reliable engine operation.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021

↩ -

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩ -

ISF3.8 CM2220 AN, Bulletin Number 4022093, Owners Manual

↩ -

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021

↩ -

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.