This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

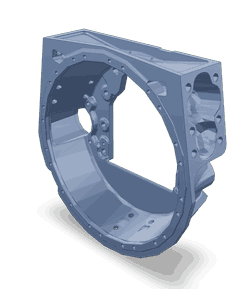

The Flywheel Housing part 3039123, manufactured by Cummins, is a component designed for heavy-duty truck engines. Cummins, a well-established name in the industry, is known for its commitment to quality and innovation in engine technology. This part is significant in the context of heavy-duty truck engines due to its role in ensuring efficient engine operation and durability.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective casing that encloses the flywheel and clutch assembly in an engine. Its primary functions include safeguarding the flywheel and clutch from external elements, maintaining alignment of the flywheel, and contributing to the overall structural integrity of the engine 1. The flywheel housing integrates with other engine components by connecting to the engine block and interacting with the transmission system through the clutch.

Purpose of the 3039123 Flywheel Housing

This Cummins part plays a role in the operation of a truck engine by providing a secure enclosure for the flywheel and clutch system. It ensures that the flywheel remains properly aligned and protected from debris and contaminants. Additionally, it facilitates the smooth transfer of power from the engine to the transmission through the clutch mechanism.

Key Features

The 3039123 is characterized by several key features that enhance its performance and durability. It is constructed from high-strength materials to withstand the rigors of heavy-duty applications. The design includes precise machining for optimal fit and function, as well as features that promote efficient heat dissipation. Additionally, the housing may incorporate unique characteristics such as integrated mounting points for accessories or enhanced sealing to prevent leaks.

Benefits

This part offers several benefits that contribute to improved engine performance, durability, and reliability. Its robust construction and precise design help to ensure consistent engine operation under demanding conditions. The housing’s ability to protect the flywheel and clutch system from external elements contributes to the longevity of these components. Furthermore, its design may facilitate easier maintenance and operational efficiency by allowing for straightforward access to the flywheel and clutch during service intervals.

Installation Process

Installing the 3039123 involves several steps to ensure proper fit and function. The process begins with preparing the engine block for the housing, which may include cleaning and inspecting the mating surfaces. The housing is then positioned over the flywheel and secured in place using the appropriate fasteners. It is important to follow the manufacturer’s guidelines for torque specifications to ensure a secure fit. Specific tools, such as torque wrenches, may be required to complete the installation.

Troubleshooting Common Issues

Common problems associated with flywheel housings can include leaks, misalignment, or damage to the housing itself. Symptoms to watch for may include unusual noises, difficulty shifting gears, or visible signs of leakage. Potential causes can range from improper installation to wear and tear over time. Troubleshooting steps may involve inspecting the housing for damage, checking the alignment of the flywheel, and ensuring that all fasteners are properly tightened.

Maintenance Tips

Regular maintenance practices are important for ensuring the longevity and optimal performance of the 3039123. Inspection tips include checking for signs of wear, corrosion, or damage during routine engine maintenance. Cleaning procedures may involve removing any accumulated dirt or debris from the housing and its surrounding areas. Additionally, it is important to follow the manufacturer’s recommendations for inspection intervals and any specific maintenance procedures related to the flywheel and clutch system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the heavy-duty truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to quality is evident in its rigorous testing and validation processes, as well as its focus on continuous improvement and customer satisfaction.

Role of Part 3039123 Flywheel Housing in Engine Systems

The flywheel housing, identified by part number 3039123, is an integral component in the operation of engine systems. It encases the flywheel, which is a heavy wheel attached to the crankshaft of an engine. This housing not only protects the flywheel but also plays a significant role in the efficient functioning of several interconnected components.

Interaction with the Flywheel and Clutch System

The flywheel housing is designed to securely hold the flywheel in place. The flywheel, in turn, engages with the clutch system. When the clutch is engaged, the flywheel transmits power from the engine to the transmission, allowing the vehicle to move. The housing ensures that this transmission of power is smooth and efficient by maintaining the alignment and integrity of the flywheel.

Support for the Starter Motor

Another key interaction is with the starter motor. The flywheel housing provides a mounting surface for the starter motor, which is essential during engine start-up. The starter motor engages with the flywheel to crank the engine, and the housing ensures that this engagement is precise and reliable.

Integration with the Engine Block

The flywheel housing is typically bolted to the rear of the engine block. This connection is vital for the structural integrity of the engine, as it helps to distribute the forces generated by the engine’s operation. The housing must be robust enough to withstand these forces while maintaining a secure fit with the engine block.

Role in Vibration Dampening

One of the less obvious but important functions of the flywheel housing is its role in vibration dampening. The housing helps to absorb and dissipate the vibrations produced by the engine, contributing to a smoother operation and reducing wear on other components 2.

Connection to the Exhaust System

In some engine configurations, the flywheel housing may also interact with components of the exhaust system. This interaction can include mounting points for exhaust manifolds or other exhaust components, further integrating the housing into the overall engine system.

Facilitation of Maintenance and Repairs

Finally, the flywheel housing is designed with maintenance and repairs in mind. It often includes access points or removable panels that allow mechanics to service the flywheel, clutch, and other related components without requiring extensive disassembly of the engine. This design consideration enhances the ease of maintenance and reduces downtime for repairs.

Conclusion

The 3039123 Flywheel Housing is a critical component in the operation of heavy-duty truck engines, offering robust protection and efficient power transmission. Its integration with various engine systems, including the flywheel, clutch, starter motor, and exhaust system, underscores its importance in engine performance and durability. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring long-term reliability and efficiency in engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.